Reliability Interview: Steven Mjoen, Catalyst Paper

Read More »Reliability and Maintenance

R&M Tips: Lubrication

Inspecting sight glasses is oil analysis in its simplest form. When done correctly, machine inspections can often uncover potential issues before they become catastrophic. Aside from checking for oil level, you should also be concerned with oil color, clarity, signs of foam or water, and staining on the glass itself. Getting more from your lube inspections is achievable by digging ...

Read More »R&M Tips: Better Grouting Practices

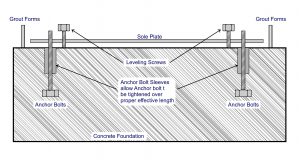

As our infrastructure ages, some say that grout failures are inevitable. However, poor base installation practices often reduce the life of our equipment. Here are some examples.

Read More »A new resource for R&M professionals

For more than a decade, TAPPI has partnered with IDCON to provide its members with valuable information about reliability and maintenance issues in the pulp and paper industry. That’s why it’s exciting to finally be inaugurating this new section in Paper360°, TAPPI’s official member magazine. I think a humming paper machine—whether it’s running tissue, kraft, liner, or a specialty grade—is ...

Read More »Leadership in Reliability & Maintenance – The Operations and Maintenance Partnership

World-class performance can only be achieved in a reliability partnership work system. This graphic shows the engineering, maintenance, and operations partnership, with key responsibilities for reliability.

Read More » Paper 360

Paper 360