The 2020 pandemic brought many challenges to the pulp and paper industry, including longer lead times on spare parts deliveries and difficulties bringing supplier SMEs (subject matter experts) from overseas due to travel restrictions. Considering its aged installed machinery, North American pulp and paper mills cannot remain competitive in the globalized market without proper maintenance practices. Additionally, the industry’s aging workforce increases dependency on technology and equipment suppliers’ knowledge and support.

CHALLENGE #1: AGING WORKFORCE AND COVID-19-RELATED TRAVEL RESTRICTIONS

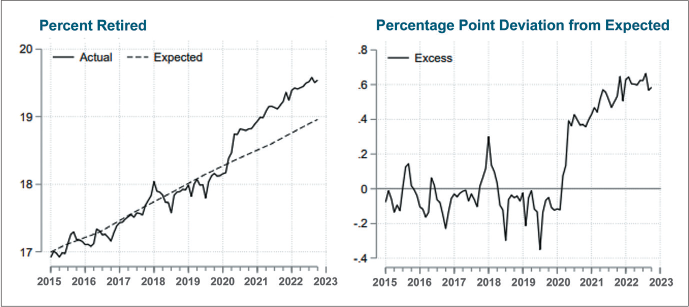

In his article for the May/June, 2017 issue of Paper360°, John A. Neun discussed the impact of an aging workforce. TAPPI recognized what they called the “retirement tsunami”1, meaning that many workers were retiring, taking their knowledge and experience with them. But as Montes et al showed in 2022, the number of Americans retiring during the pandemic years increased even more2, exceeding the number of retirees expected in the period (Fig.1).

In practical terms, this brought many unexperienced workers to mills, with limited technical or historical knowledge of the equipment to be maintained. They need to rely on external knowledge sources to plan their maintenance schedules. Without properly planning shutdowns, it becomes more difficult to get parts, labor, and experienced suppliers in time for the annual outages.

If external help is needed, the mills must contact their main OEMs (original equipment manufacturer), whose workforce is also aging and retiring. So, they need to turn to their headquarters/technology units in Europe for help. Yet between March 2020 and November 2021, the USA was under a travel ban that made it very difficult to bring in foreign nationals.

These factors show how susceptible the industry is in terms of technical knowledge. Technology usage must be increased to retain the mills’ histories, best practices, knowledge, and experiences.

CHALLENGE #2: MANAGING SHORTAGES

In manufacturing facilities, high spare parts inventory levels equal high costs. For years, our mills have pursued a “lean mentality,” trying to keep these numbers at an absolute minimum. But OEMs also have similar goals and targets and keep their spare parts inventories at a minimum. This sensitive balance between short inventories in both supplier and mill warehouses worked well for many years, until the pandemic disrupted the whole global supply chain system. Suddenly, it became much harder for the mills to receive spare parts in time for their annual shutdowns.

Matthew Pereira, Mainway Handling Systems3, suggests some lessons to be learned in terms of Spare Parts Management after the COVID-19 pandemic. Below are his recommendations, with some adaptations to the pulp and paper industry reality:

- “Just in time” is not good enough. Plan for shutdowns early.

- OEMs should not deliver spare parts only a few days prior to shutdown. There should be enough time to review the parts received before the work is done.

- Maintenance planners must conclude the shutdown schedules earlier, and they should not assume that the OEMs will expedite spare parts deliveries every time.

- Procurement departments must work faster, respecting the long lead times provided by OEMs for spare parts.

- Communication is key to winning.

- Maintenance planners should communicate with the OEM reps in a pre-determined frequency, making sure that the spare parts deliveries are on track.

- OEM reps must always determine who is their main point of contact for each maintenance job.

- Have seamless data integration.

- Excel spreadsheets are antiquated tools and unreliable when it comes to spare parts management.

- Technology should be your best friend. Pursue a digitalization project to modernize your supply chain and preventive maintenance systems.

- Do not rely only on lean inventory models.

- The world is not safe from new supply chain disruptions caused by several factors.

- Increase your spare parts inventories.

- Meet with your main OEMs and understand their spare parts inventory system.

CHALLENGE #3: BUDGET TIMING AND SHUTDOWN PLANNING

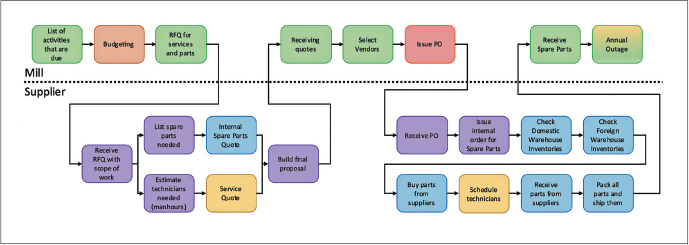

Each mill has its own budgeting cycle, which includes maintenance budgets. This is often an impediment for early annual outages planning, as the maintenance planners cannot issue Purchase Orders—or even know for sure, or with much advance notice—what activities will be done during a specific shutdown. According to my past experience working for a major OEM for the pulp and paper industry, to ensure a trouble-free outage in terms of equipment maintenance, the spare parts should be ordered at least 6-8 months prior to the annual outage (Fig. 2). This means it is important to include the financial, procurement, and maintenance departments in the planning phase.

RECOMMENDATIONS

Pulp and paper mills must reduce dependency on OEMS by using technology to optimize maintenance planning and retain technical knowledge. When it comes to OEMs, paper producers must use their technical knowledge and their facilities, building spare parts consignment agreements, making sure that spare parts are always available with shorter lead times. To reduce maintenance costs and bring technical experts to the mills, maintenance package bundles, including parts and technical advisory, should be preferred instead of buying parts separately from technical advisors and labor packages.

Finally, the lean mentality, when it comes to spare parts, must be reviewed, both by paper producers and by equipment suppliers. To avoid future vulnerabilities, spare parts inventories should be increased.

Paper 360

Paper 360