Keit’s IRmadillo FTIR spectrometer is built to last in harsh environments

SPONSORED CONTENT BY KIET INDUSTRIAL ANALYTICS

Although originally conceived to measure the atmosphere around Mars, the Keit IRmadillo Fourier transform infrared (FTIR) spectrometer has found a new home in pulp and paper mills.

How could an instrument designed to work around the Red Planet find a home in a pulp mill? To survive the rigors of space travel, the design had to be low power, low maintenance, compact, vibration resistant (to survive launch blasts) and able to work consistently well in an exceptionally harsh environment: Other than lift-off, conditions similar to a chemical pulp mill.

The technology was based on the belief that a static-optical design was the best solution for measuring in space. Standard FTIR spectrometers are susceptible to vibration, thus impossible to use on a satellite and impractical for in situ industrial use.

To harvest the information-rich area of the mid-infrared spectral region for analysis, a new FTIR design was needed. The unit had to be fixed with no moving parts. The IRmadillo is the result.

However, it was soon realized that there were many closer applications here on earth. In 2013, Keit Industrial Analytics became a spin off company of the European Space Agency Business Incubation Centre, managed by the UK Science and Technology Facilities Council and is based in Oxfordshire, UK.

CEO Dan Wood explains, “We were spun out to explore the technology for industries here on earth and we started capitalizing on the instrument’s robustness and reliability.”

As Wood says, it may not be pretty, but it is solid, which makes it ideal for heavy and dirty industries such as pulp and paper. But it was not the pulp and paper industry where Keit first devoted its efforts.

“We originally focused on the chemicals and oil and gas space as we thought that was a good fit for the ethos behind the instrument,” Wood adds. However, the industry is “so entrenched in the near infrared space that our mid-IR instrument was a big step for them.”

“We’re still operating in those spaces but the requirements for additional certifications means it’s slower moving than other industries,” Wood says.

Other industries of interest include the pharmaceutical sector, industrial biotech, and edible oil refining.

But, it took a sharp-eyed Swedish distributor to realize that the pulp and paper industry had many opportunities. “We did an initial proof of concept in a green liquor line at a Swedish mill and had good results,” Wood explains.

One unit: many applications

The chemical recovery sector has shown itself to be an ideal place for the IRmadillo to prove itself. Keit has instruments installed in green liquor (smelt dissolving tank outlet), white liquor (digester feed) and black liquor (weak, strong and firing liquors).

Although most of the work is on the pulping side, papermaking has not been neglected. There is potential to measure stickies. There is one installed on an OCC line, but it is still in the preliminary stages of development.

Wood says there are at least eight mills with an IRmadillo but expects that number to rise to at least 12 by year’s end.

One global producer has installed five of the units. Its spokesperson said one of its mills needed to measure a chemical compound in its 50% black liquor stream. As its original supplier no longer made that equipment, a search was done and Keit was discovered.

“I got involved with the project to verify the unit’s operation,” the spokesperson explains. “I discovered it could measure many other properties, for example, additional chemical species in the black liquor stream.”

Because the IRmadillo can multi-task, the company decided to create additional sampling program protocols. This allowed it to build additional predictive models with the instrument. This is one of the strengths of the unit.

The spokesperson cautions that it is still early days and the company is working to get the new predictive models operational. “We are working with Keit to get enough sampling done to develop the predictive models.”

Keit’s Wood adds, “We’re building up the calibrations on them and the next step is our customer working on actually using that data to make improvements.”

The first IRmadillo is in service, and the others are in various stages of implementation. It is hoped that the next four will be operational by late 2023.

And, it is taking full advantage of the IRmadillo’s versatility, using it in five different applications. Besides the original 50% black liquor stream, the unit has been installed in white liquor, weak black liquor and green liquor streams.

For the liquor applications, the client is measuring various physical properties and chemical species. It is trying to determine what predictive models can be built with what degree of accuracy.

There is also one on a pulp line to see if it can determine stickies content in pulp. Keit did a paper on this, and the client picked up on the idea.

Two of the units were installed as part of a larger digester optimization project while the others were standalone purchases

Although attractive for its ability to do more than one job, the customer also favored the unit’s ruggedness that was not deterred by the harsh environment pulp mills are known for.

Also, once installed, costs to the mill are minimal. It is a self-contained unit with no need for separate controls. Sampling procedures are also simple.

The client notes that high-quality instrument air is a must. Therefore, an air filter and drying unit may be needed with the spectrometer. A strong base and protective cover are also needed.

Simplicity is another key feature of the IRmadillo. It has its own controller with two ethernet (cat5) cables coming out of the back. They can be used to remote into the instrument to control it and to “talk” to a mill’s distributed control system (DCS) over modbus. Right now, the unit still needs additional calibration, but Keit is working on pre-calibration to truly make it a “plug and play” operation.

No training is needed at the mill. The unit starts recording spectra from the moment it is powered on. Keit takes care of calibrating it remotely using data provided by the customer on its typical sampling regime.

The client concurs. “We really just want to provide a measurement to operators. The unit is self-contained; it’s really just outputting a signal. We’re using it as an engineering tool to identify abnormal operations, production upsets and how they are affecting production targets.”

The units can be retrofitted easily. Keit has designed the IRmadillo to be compatible with 2-in. ANSI flanges so the mill needs only to weld one on and directly insert into the pipe.

As well as standalone purchasing, Keit is also working with OEMs so the IRmadillo can be selected as the preferred option for mills undergoing larger investments.

Goals can be varied

Mills will invest in projects for many reasons: increased production, improved quality, raw material and/or energy consumption reduction, overall process optimization.

For the client with five units, the aim was “somewhat exploratory, “What can we measure with a degree of accuracy? I’m trying to figure out practically what can we measure in all these streams.”

If it all comes to fruition, there will be numerous benefits: energy efficiency (green liquor stream); for stickies, it is a machine availability issue; being able to measure black liquor properties will help predict boiler availability so that is a production issue.

Wood believes that the main benefit will be process optimization. “That can result in either an increase in yield or improved throughput, especially batch processes, which may complete earlier than otherwise thought.”

In the future, the client cited in this piece says it may be able to be used for closed loop control with some of the properties they are measuring, but this is still a ways away. “That is the ultimate goal.”

He also speaks of some of the challenges to watch for, most notably, the need to control fouling of the units in a mill environment. “Green liquor is a very difficult environment.”

A good level of calibration must be maintained so the mill has a high level of confidence in the accuracy of the models that have been developed. He again stresses the need for instrument air to be very clean.

“From our standpoint, we have had a good experience with the units; they are very responsive. We knew going in that the instrument was under development, and we are trying to figure out the best applications.”

Technically speaking

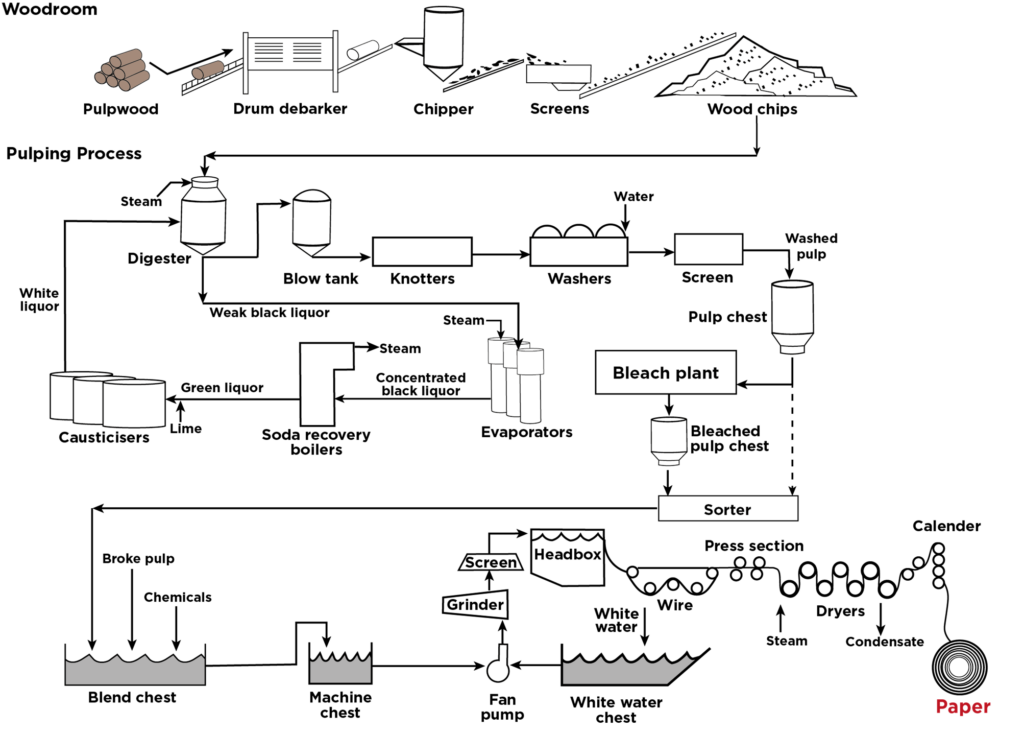

Delving deeper into the IRmadillo’s technical capabilities and applications, Figure 1 shows a kraft pulp process with potential installation points for the instrument.

For example, by measuring the concentration of both sodium sulfide and sodium carbonate, it can calculate how much lime is needed to effectively causticize back to sodium hydroxide. Stabilizing recausticizer operations through better control can help improve mill efficiency.

Although not discussed as much, in papermaking applications the IRmadillo can provide real-time measurement of chemicals present in the white water chest such as residual wet strength chemicals as well as other chemical additives.

Quantitative as well as qualitative measurements of different process chemicals can be achieved at the same time. Some of the chemicals it can monitor include: sodium carbonate; sodium sulfide, sodium sulfate; sodium sulfite; sodium hydroxide; metal hydroxides, ammonia, sulfuric acid and wet strength additives.

There is no maximum concentration and the scales can be adjusted depending on the chemical of interest. For example, a mill can monitor NaOH in % terms while watching the ppm level of contaminants at the same time.

Besides quantitative analyses of chemicals, the IRmadillo can do the same for process characteristics. Properties it can measure include: active alkali, effective alkali, sulfidity and causticity.

Qualitatively, the IRmadillo can provide readings such as “within specification”, “contamination spotted” and the like. Calibration is more flexible in this case and designed to show overall types of process conditions, rather than fixed chemical concentrations.

Keit can build a qualitative calibration after the unit has been in use for a time, so a mill can look back at the quality of its processes, showing where a process is likely to go over time. It should be noted that a mill can run a qualitative and quantitative calibration at the same time.

The software contains its calibration and runs the measurement in real time. This means a mill receives a live measurement of chemical concentrations (usually in %wt but a mill can choose its own units) over the whole process.

The IRmadillo will also talk to a mill’s DCS or SCADA system. Thus, it can communicate directly with existing infrastructure and be incorporated into feed forward and feed backward process control schemes.

Earlier, direct insertion into a flanged connection was discussed. This means the analyzer is measuring the same liquor as is flowing through the process pipeworks and benefits from any pipework cleaning being done. This does require the fitting of a flanged T-piece. This is also the default setting for the integrated ultrasonic descaling package.

Mills may opt for a recirculation loop and a flow cell. This method uses a flow cell on the IRmadillo probe coupled with a recirculation/extraction loop.

The process liquid does not need any special conditioning, just pumping around a short circuit into the flow cell and then back into the main pipeline. This method is much faster and does allow for the spectrometer to be removed from the process and cleaned separately.

This set up also allows for a separate cleaning cycle, which is beneficial if the installation point is known to foul over time.

For more information, contact [email protected].

Paper 360

Paper 360