What is a component? IDCON uses the word “component” to describe an item that is highly repetitive for preventive maintenance purposes. For example, the AC motor on the infeed hydraulic unit is composed of several components or machine elements. The infeed hydraulic unit is a highly repetitive unit often found in paper mills, refineries, mines, etc. AC motors are a component that is reoccurring as well.

Read More »Tag Archives: maintenance

How to Document Cost-Effective Maintenance Tasks Part 5: Equipment List

So, we have completed our Criticality Analysis. What’s next? In Part 5 of this series, we will cover the importance of using an equipment list while performing Preventive Maintenance, how to use the equipment list most effectively, and provide an example and template of a well-organized equipment list.

Read More »How to Document Cost-Effective Maintenance Tasks Part 2: The Productivity Circle

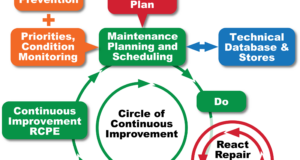

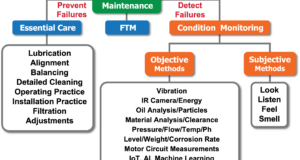

Part 2 in this series covers how Preventive Maintenance fits into the overall Reliability and Maintenance cycle. Figure 1 shows IDCON’s Productivity Circle which is used to demonstrate the overall partnership between Operations and Maintenance.

Read More »How to Document Cost-Effective Maintenance Tasks Part 1: Preventive Maintenance Definition

IDCON’s latest series will detail the correct way to document cost-effective maintenance tasks. The first thing to do is go back to the basics. Part 1 will cover the background and theory of how to achieve the correct tasks and documenting Preventive Maintenance tasks.

Read More »LE Introduces Easy Bar with Almasol

Easy-To-Apply Melting Bars Prevent Costly Wear in Rotary Kilns and Dryers

Read More »Smart Strategies for Pulp Mill Optimization: Take Care of ESP Fundamentals

Like any complex system, a pulp mill is only as strong as its weakest link. The challenge for teams is how to build intelligent optimization and maintenance strategies that check all the boxes from an engineering and equipment perspective.

Read More »Reliability Engineers – what is their role at your mill?

by Christer Idhammar, Founder IDCON, Inc. – helping mills become world class maintenance organizations During a recent reliability and maintenance conference, we met several Reliability Engineers telling us they found their job different from what they expected it to be. Many of them had graduated as reliability engineers and had learned all about Mean Time To Repair (MTTR), Mean Time ...

Read More »Execute! Execute! Execute!

Keeping things simple when you implement maintenance processes is the foundation for successful execution on the plant floor.

Read More »90% of all Training is Wasted

Article written by Christer Idhammar, Founder, IDCON INCI believe that most training efforts are wasted unless the training is focused on the training needs of each individual. After going through training, a person should immediately apply the new skills. As the saying goes, “If you do not use it, you lose it.”There are many examples where the above has not ...

Read More »Connecting People, Work Processes, and Technology to Improve R&M Management

Five key steps that blend together people, work processes, and technology to give your organization a solid reliability and maintenance foundation.

Read More » Paper 360

Paper 360