by Christer Idhammar, Founder IDCON, Inc. – helping mills become world class maintenance organizations

During a recent reliability and maintenance conference, we met several Reliability Engineers telling us they found their job different from what they expected it to be.

Many of them had graduated as reliability engineers and had learned all about Mean Time To Repair (MTTR), Mean Time To Failure (MTTF), Mean Time Between Failures (MTBF), Weibull charts, Failure Mode Effect Analyses (FMEA),reliability Centered Maintenance (RCM),etc.

All good stuff! But not necessarily the most practical for their day- to-day work

They told us that in their job they rarely used any of what they learned.

Their mills did not even have a policy that included maintainability and reliability analyses and reviews when they specified new equipment.

Some helped planners to document standard job plans, participated in failure investigations, but not with a structured method such as a Root Cause Problem Elimination (RCPE). Some were assigned to set up a Preventive Maintenance program and tried to use RCM but soon found it too complicated for what they wanted to accomplish.

There seems to be a gap between college theory and the real world. The real world is about people and reactive behavior not just theory. Just because you have an excellent process documented does not necessarily mean it is being followed.

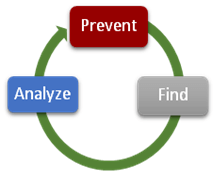

To simplify the role for new reliability engineers we suggest following:

1. Prevent problems from occurring.

- – Reliability and Maintainability design

- – Cleaning

- – Lubrication

- – Alignment of components

- – Equipment operating procedures

- – Filtration of lubricants, seal water etc.

- – Storage handling of spares

- – Etc.

2. Find includes early detection of problems

- – Predictive Maintenance

- – Basic inspections

3. Analyze equipment failures and data to propose solutions.

- – Event reports

- – Equipment history triggers

- – Condition Monitoring reports

Close the loop by implementing the actions can be taken to 1. prevent and 2. find problems early.

Many organizations are more reactive than proactive which means that many reliability engineers are caught up in this environment and they will not spend enough time on what they should do.

Are your Reliability Engineers Preventing- Finding-Analyzing equipment failures? or are they doing something else?

Paper 360

Paper 360