Torbjörn Idhammar, President, IDCON INC

Using an Equipment Database for More Organized Preventive Maintenance

So, we have completed our Criticality Analysis. What’s next? In Part 5 of this series, we will cover the importance of using an equipment list while performing Preventive Maintenance, how to use the equipment list most effectively, and provide an example and template of a well-organized equipment list.

Equipment List

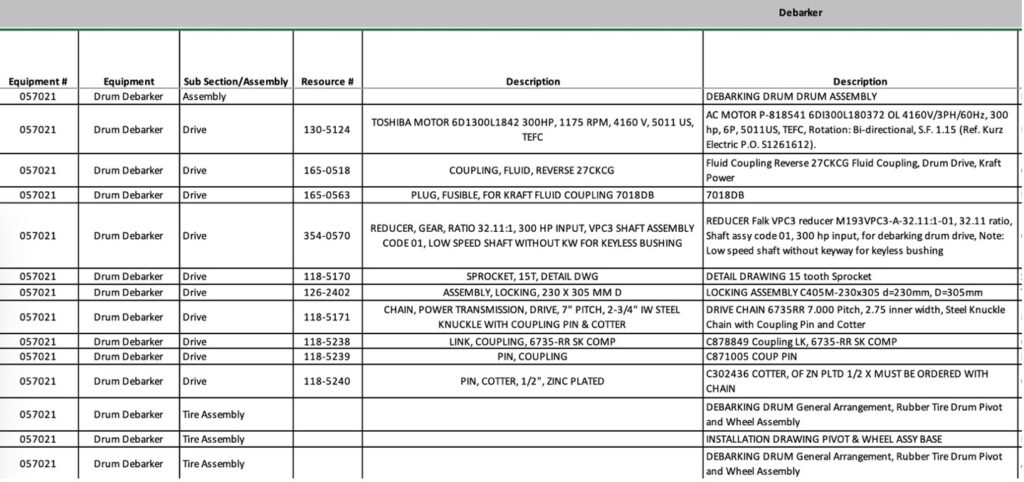

After completing the Criticality Analysis, we have a list of equipment that needs Preventive Maintenance and we know which equipment needs our attention first (see Figure 1).

Equipment Database and Existing Preventive Maintenance

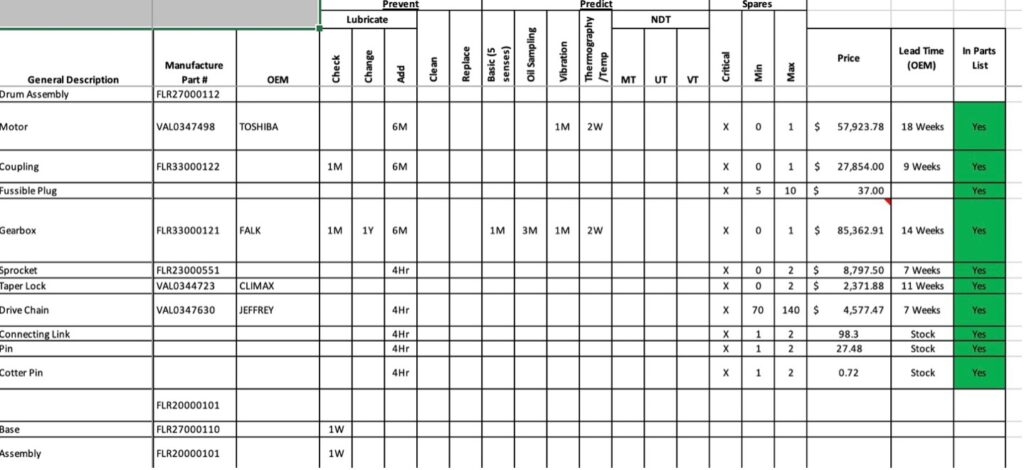

Before we go out into the field, we need to access the equipment database in the Computerized Maintenance Management System (CMMS) and search for existing PMs for the piece of equipment to be worked on first. Say we have determined that a simple hydraulic unit as the equipment with the most critical PMs.

For that hydraulic unit, in the CMMS there may be on-the-run Preventive Maintenance; routes for lubricators, mechanics, and operators; vibration analysis on the motor and pump; infrared; checking the level of the tank; electrical routes checking solenoid valves. This is all very important information, so make sure your team knows where to find it in the CMMS.

Now that we have the equipment database and have determined the existing PMs, we can transfer the information to a list and start our Preventive Maintenance inspection routes.

Using the Equipment List

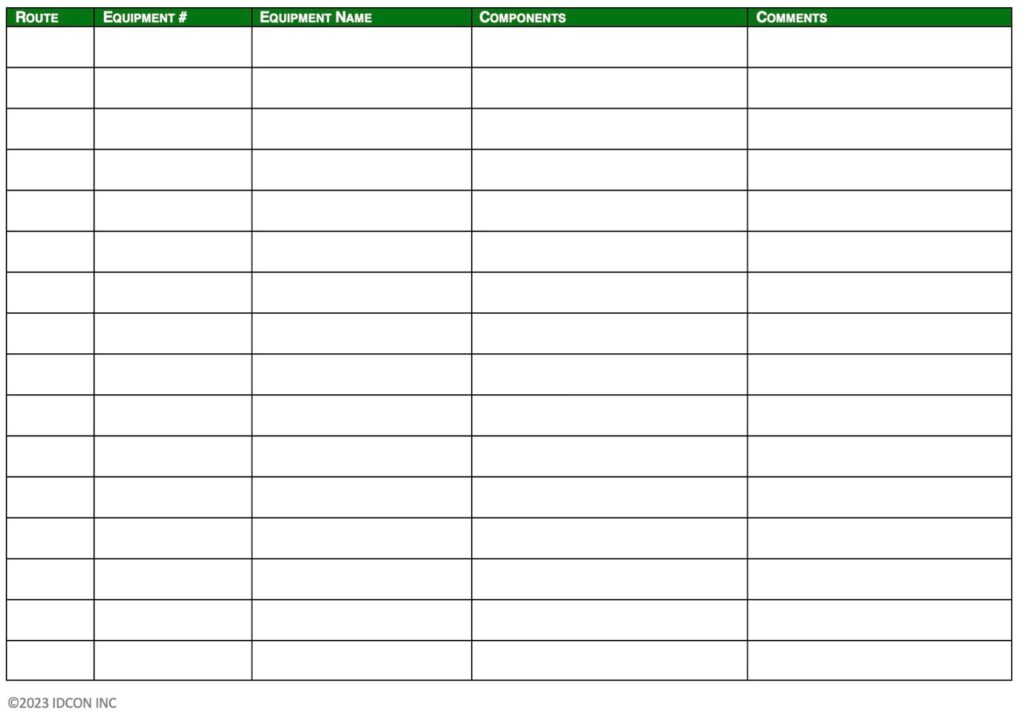

As you know, at IDCON we like to Keep it Simple. The template below shows the easy-to-use equipment list format that has been working for IDCON for years.

This sheet contains sections for the route number (the order in which the inspection route should be blocked for on-the-run inspections), the equipment number and name, components, and a section for notes and comments.

Once you have this list filled out, you are ready to go out on the field. Remember to bring your list on a clipboard, take your phone so you can take pictures of the equipment at the job site, your PPE such as safety glasses and hard hat, and head out to the plant.

Watch Tor’s video related to this article on our Youtube Channel.

Sign your organization up for IDCON’s Develop and Manage Preventive Maintenance Training today!

Torbjörn Idhammar is president and CEO of IDCON, Inc. and section editor of Reliability & Maintenance, for Paper360° magazine. Contact him at [email protected]. For more articles, please visit: www.idcon.com and www.maintenanceworld.com.

Paper 360

Paper 360