How to Document Cost-Effective Maintenance Tasks: Part 6

Torbjörn Idhammar, President, IDCON INC

Part 5 “Equipment List” detailed the collection of information in an equipment list, how to use that list most effectively, and the best templates to use for creating an organized equipment list.

Now, it is time to analyze the information collected from testing and inspecting equipment in the plant, mill, or mine.

Analyzing Information

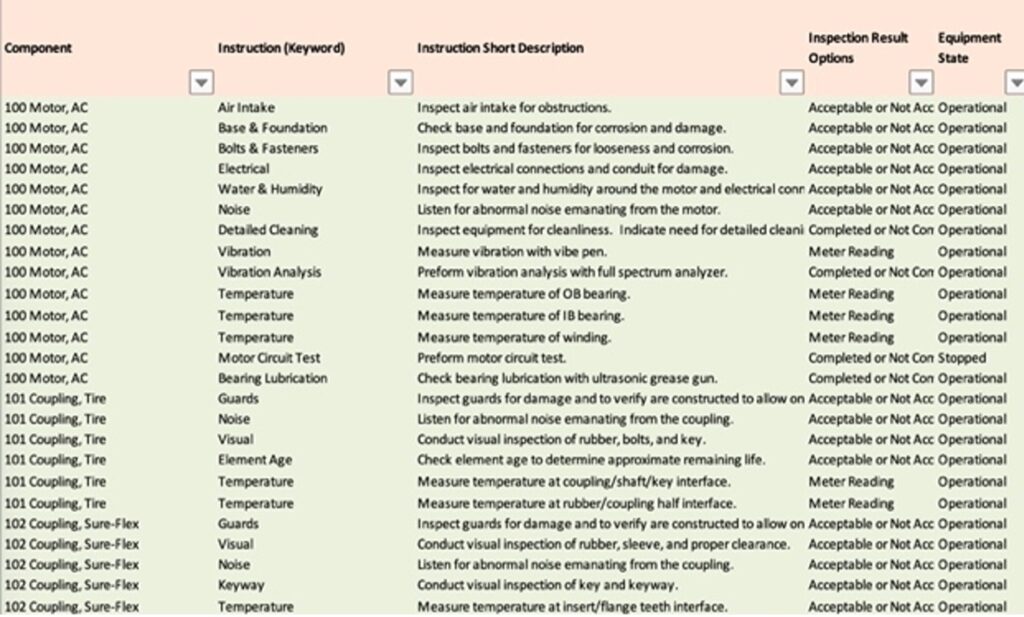

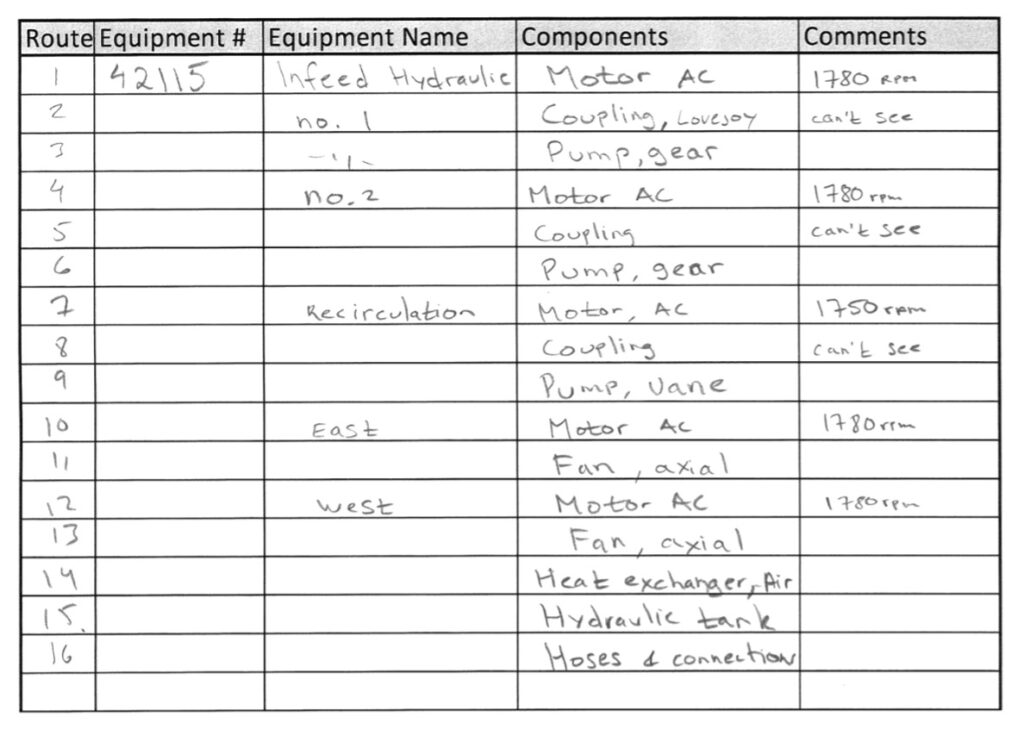

As an example, let’s continue to use the AC motor in the infeed hydraulic unit discussed in Part 5. On the sheet below, you see the Route Number (1), Equipment Number (42115), Equipment Name (Infeed Hydraulic), Components, and Comments.

It is important for the equipment to be labeled so that you don’t have to search the Computerized Maintenance Management System (CMMS) for the equipment number.

The first component on the list is the AC Motor. First, record the RPM (1,780). Then, use a stroboscope to inspect the coupling, air fans, etc. As you can see in the comments, the jaw coupling (Lovejoy) is completely hidden by guards and can’t be inspected.

This leaves a few options for the Preventive Maintenance inspection:

- Remove the guard to inspect with a stroboscope during a shutdown

- Operate until the equipment breaks down (Operate to Breakdown)

- Modify the guard

The decision will be made at the time when Preventive Maintenance is done on the equipment.

PMs Aren’t Written from a Desk

As you can see on the list, the infeed hydraulic unit has been broken down into 16 different components that have been inspected in the field. Field inspections are critical when writing PMs – you can’t write a Preventive Maintenance task from your desk by searching the CMMS.

If someone tried to write this information from a desk instead of while looking at the equipment itself in the plant, mill, or mine, they wouldn’t know that the jaw couplings were covered to the point that they couldn’t be inspected. How would we get the valuable RPM reading? What if one of the motors isn’t listed in the CMMS? How can we be sure which type of coupling or pump is on the equipment without an inspection of the equipment in the field?

Components

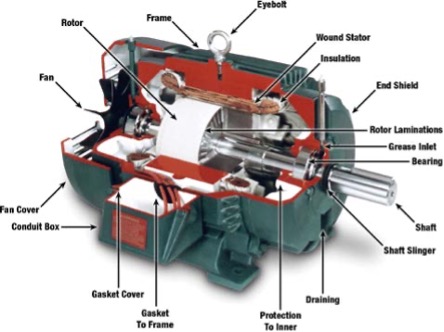

What is a component? IDCON uses the word “component” to describe an item that is highly repetitive for preventive maintenance purposes.

For example, the AC motor on the infeed hydraulic unit is composed of several components or machine elements. The infeed hydraulic unit is a highly repetitive unit often found in paper mills, refineries, mines, etc. AC motors are a component that is reoccurring as well.

It is important to establish standard Preventive Maintenance tasks/activities (on the run, shutdown, lubrication, etc.) for repetitive units (components) such as AC motors that can be applied repeatedly. Certain equipment being in different conditions than other components of the same type, for example being in a particularly hot or wet location in the plant, will have different requirements, but it is useful to have a set of standard inspections that will always be done to repetitive units.

The same idea can be applied to the jaw coupling.

There should be standard inspections that apply to any jaw coupling, but there is a different condition for the couplings on our example unit – they are covered by the guard. This means that different requirements will be needed for this component. The decision will need to be made to modify the guard, do a shutdown inspection and take it apart, or allow it to operate to breakdown.

Component Database

Best practice is to create a database containing the highly repetitive, standard components with standard Preventive Maintenance tasks to perform on the run and during a shutdown. With this information, the PM tasks can be refined and adjusted based on any different or special circumstances of the component or equipment.

Watch the video for a complete image of the component database and more detail and examples.

Torbjörn Idhammar is president and CEO of IDCON, Inc. and section editor of Reliability & Maintenance for Paper360° magazine. Contact him at [email protected]. For more articles, please visit: www.idcon.com and www.maintenanceworld.com.

Paper 360

Paper 360