What is a component? IDCON uses the word “component” to describe an item that is highly repetitive for preventive maintenance purposes. For example, the AC motor on the infeed hydraulic unit is composed of several components or machine elements. The infeed hydraulic unit is a highly repetitive unit often found in paper mills, refineries, mines, etc. AC motors are a component that is reoccurring as well.

Read More »Author Archives: Robin Kent

How to Document Cost-Effective Maintenance Tasks Part 5: Equipment List

So, we have completed our Criticality Analysis. What’s next? In Part 5 of this series, we will cover the importance of using an equipment list while performing Preventive Maintenance, how to use the equipment list most effectively, and provide an example and template of a well-organized equipment list.

Read More »How to Document Cost-Effective Maintenance Tasks Part 4: Criticality Analysis

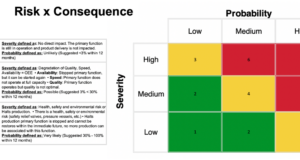

Part 4 of this series will cover how to decide what PMs we should document first, and typically we do a criticality analysis. As we like to say at IDCON: Keep it simple. It is best to keep the criticality analysis as simple as possible. As with any type of criticality analysis, the formula is Risk x Consequence. The “risk” represents the probability of the failure or breakdown occurring, and the “consequence” could refer to safety, environmental, high cost, lost production, etc.

Read More »How to Document Cost-Effective Maintenance Tasks Part 3: Process for Documenting Preventive Maintenance Tasks

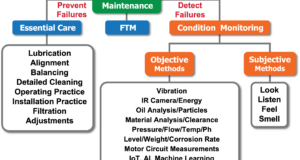

Part 3 in this series focuses on Preventive Maintenance documentation processes. In order to document a cost-effective preventive maintenance system, there must be a clear and established process in place for how to document PMs. It is not enough to rely on vendor information and personal experience alone.

Read More »How to Document Cost-Effective Maintenance Tasks Part 2: The Productivity Circle

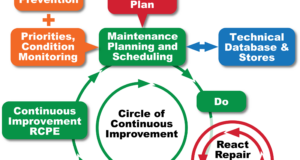

Part 2 in this series covers how Preventive Maintenance fits into the overall Reliability and Maintenance cycle. Figure 1 shows IDCON’s Productivity Circle which is used to demonstrate the overall partnership between Operations and Maintenance.

Read More »How to Document Cost-Effective Maintenance Tasks Part 1: Preventive Maintenance Definition

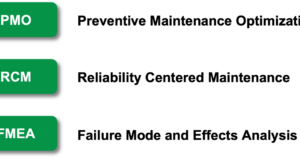

IDCON’s latest series will detail the correct way to document cost-effective maintenance tasks. The first thing to do is go back to the basics. Part 1 will cover the background and theory of how to achieve the correct tasks and documenting Preventive Maintenance tasks.

Read More »Reliability Engineers – what is their role at your mill?

by Christer Idhammar, Founder IDCON, Inc. – helping mills become world class maintenance organizations During a recent reliability and maintenance conference, we met several Reliability Engineers telling us they found their job different from what they expected it to be. Many of them had graduated as reliability engineers and had learned all about Mean Time To Repair (MTTR), Mean Time ...

Read More »Dissimilar Metal Corrosion – what’s the impact?

by Owe Forsberg, Vice President IDCON, Inc. – helping mills to become world class maintenance organizations. Here’s a real-life root cause analysis (RCA) for you to think about. A trailer was repaired after the side was scraped. The bolts that held the cross members to the aluminum frame on the side were replaced. The trailer passed the DOT inspection. One ...

Read More »90% of all Training is Wasted

Article written by Christer Idhammar, Founder, IDCON INCI believe that most training efforts are wasted unless the training is focused on the training needs of each individual. After going through training, a person should immediately apply the new skills. As the saying goes, “If you do not use it, you lose it.”There are many examples where the above has not ...

Read More »Driving lesson for reliability

If you’ve been in the industry since the late 80s or early 90s, you may be familiar with the image in this video. In order to have reliable production your mill manager, operations manager and maintenance manager need to work together to see the whole picture. Christer Idhammar, IDCON company founder and reliability and maintenance management expert, takes you through ...

Read More » Paper 360

Paper 360