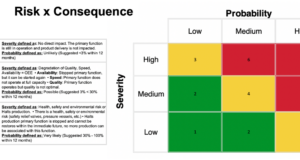

Part 4 of this series will cover how to decide what PMs we should document first, and typically we do a criticality analysis. As we like to say at IDCON: Keep it simple. It is best to keep the criticality analysis as simple as possible. As with any type of criticality analysis, the formula is Risk x Consequence. The “risk” represents the probability of the failure or breakdown occurring, and the “consequence” could refer to safety, environmental, high cost, lost production, etc.

Read More »Tag Archives: reliability

How to Document Cost-Effective Maintenance Tasks Part 3: Process for Documenting Preventive Maintenance Tasks

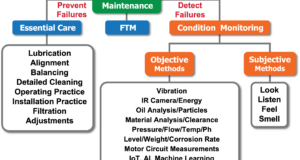

Part 3 in this series focuses on Preventive Maintenance documentation processes. In order to document a cost-effective preventive maintenance system, there must be a clear and established process in place for how to document PMs. It is not enough to rely on vendor information and personal experience alone.

Read More »How to Document Cost-Effective Maintenance Tasks Part 2: The Productivity Circle

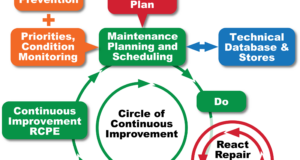

Part 2 in this series covers how Preventive Maintenance fits into the overall Reliability and Maintenance cycle. Figure 1 shows IDCON’s Productivity Circle which is used to demonstrate the overall partnership between Operations and Maintenance.

Read More »How to Document Cost-Effective Maintenance Tasks Part 1: Preventive Maintenance Definition

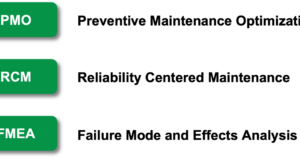

IDCON’s latest series will detail the correct way to document cost-effective maintenance tasks. The first thing to do is go back to the basics. Part 1 will cover the background and theory of how to achieve the correct tasks and documenting Preventive Maintenance tasks.

Read More »Why People Are Important to Operational Excellence

The importance of considering human factors to reduce injury potential.

Read More »Connecting People, Work Processes, and Technology to Improve R&M Management

Five key steps that blend together people, work processes, and technology to give your organization a solid reliability and maintenance foundation.

Read More » Paper 360

Paper 360