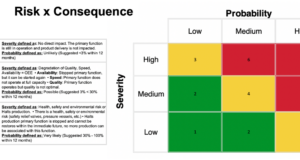

Part 4 of this series will cover how to decide what PMs we should document first, and typically we do a criticality analysis. As we like to say at IDCON: Keep it simple. It is best to keep the criticality analysis as simple as possible. As with any type of criticality analysis, the formula is Risk x Consequence. The “risk” represents the probability of the failure or breakdown occurring, and the “consequence” could refer to safety, environmental, high cost, lost production, etc.

Read More »Tag Archives: Reliability & Maintenance

How to Document Cost-Effective Maintenance Tasks Part 3: Process for Documenting Preventive Maintenance Tasks

Part 3 in this series focuses on Preventive Maintenance documentation processes. In order to document a cost-effective preventive maintenance system, there must be a clear and established process in place for how to document PMs. It is not enough to rely on vendor information and personal experience alone.

Read More »Better Valves Improve Pulp and Paper Mill Safety

A good valve — one that’s built to last and closes completely without pressure loss or leakage — improves worker safety in a mill.

Read More »Efficiency is Key for High Capacities

At the Bohui Papers facility, Cellwood Machinery’s largest dispersing system is helping the mill produce 2,150 metric tons per day of white-top cardboard—currently the largest capacity in the world.

Read More »Going the Distance with Utah PaperBox’s Trim Removal Solution

"Since installing our PAC cutter trim removal system, we’ve been able to keep our line running at full speed and capacity, while saving hours of labor in our sheeting department.

Read More »Automating Process Cooling Can Eliminate ‘Strainer Danger’

Automated scraper strainers that filter out both micron-sized particles and oversized detritus resist clogging and fouling, minimizing maintenance and boosting production.

Read More »Thinking Beyond the Basement

Vacuum systems are essential for papermaking, and understanding the dewatering process is the key to a well-working vacuum system.

Read More »Flexible Gas Monitoring Keeps Docks, Warehouses Safe

Detecting dangerous gases with versatile, modular systems can speed compliance and construction project completion for pulp and paper facilities.

Read More » Paper 360

Paper 360