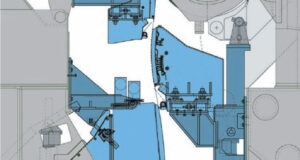

Containerboard grades require reliable strength properties, high productivity, and reduced specific energy consumption combined with a very low total cost of ownership.

Read More »Tag Archives: Reliability & Maintenance

Practical Maintenance Planning Tips, Cont.

Learn about protecting your planners so they can plan, basic elements of a standard job plan, and how to develop good job plans with these Practical Maintenance Planning Tips from IDCON Senior Consultant Leslie Skelly.

Read More »Practical Maintenance Planning Tips

Check out these quick maintenance planning tips covering Planner roles, quality work orders, and field job scoping from Leslie Skelly, Senior Consultant with IDCON INC.

Read More »3 Common Mistakes in Root Cause Failure Analysis (RCFA)

Analyzing and eliminating the root cause of a failure is a powerful tool for improving plant reliability. At IDCON, we call this process Root Cause Problem Elimination (RCPE). We find that this term more accurately defines the desired outcome of the process.

Read More »IDCON INC Reliability Tip: How to Use Root Cause Problem Elimination (RCPE) during Corrective Maintenance

Imagine you work in a mill as a mechanic and get a work order that states: Replace bearings on a press roll due to high vibration level. You complete the work and the damaged bearings and seals were replaced according to the plan. The machine was started up and is now producing paper again.

Read More »Operations Maintenance Coordinator: A Beneficial Role

TORBJÖRN IDHAMMAR, IDCON INC. Why do we need an Operations Maintenance Coordinator? Maintaining a good Reliability and Maintenance program requires sharpening existing skills and reminding ourselves of what we already know: that improving production reliability largely depends on the commitment and involvement of operations. To achieve this, assigning the role of an Operations Maintenance Coordinator (OMC) is critical. It is ...

Read More »IDCON Reliability Tip: The Gemba of Reliability and Maintenance Management

"Gemba" is a Japanese word meaning the actual place where value is created, or where actions are executed. It includes Gemba walks to the actual place to observe, learn and improve work.

Read More »Keeping it Simple – Some Principles of Successful Reliability and Maintenance Management

On April 20th at 10:30-11:00 AM (EST) in his second webinar in the “Keeping it Simple” series, Reliability and Maintenance Management expert Christer Idhammar gives you a glimpse into why “knowing why” is important in managing maintenance and how knocking bolts became the catalyst behind Christer’s philosophy. You’ll also learn some forgotten truths about managing maintenance processes. Join us through ...

Read More »How to Document Cost-Effective Maintenance Tasks Part 9: Preventive Maintenance Example

Catch up with Tor's latest installment in the series "How to Document Cost-Effective Preventive Maintenance" here.

Read More »Choosing a Maintenance Method

In terms of Maintenance Methods, there are three choices for existing equipment. They are Operate to Breakdown, Fixed Time Maintenance, and Condition Based Maintenance. Operate to Breakdown: The equipment is run until it breaks down. Fixed Time Maintenance: The replacement of parts or equipment on a fixed/scheduled frequency. Condition Based Maintenance: The problem is found and fixed at the time when it is discovered. It is a common assumption that Condition Based Maintenance is always the most cost effective. While this is commonly the case, it is not always true.

Read More » Paper 360

Paper 360