Torbjörn Idhammar, President, IDCON INC

In Part 8 of this series, we got into how to decide on which Preventive Maintenance tasks are necessary when writing a PM for equipment. Part 9 provides a Preventive Maintenance example.

Preventive Maintenance Tasks

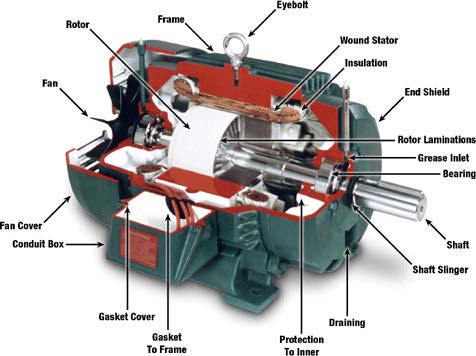

The equipment used for the example will be the same AC motor that has been used through the entire series. This process applies to any type of equipment!

Using a Database

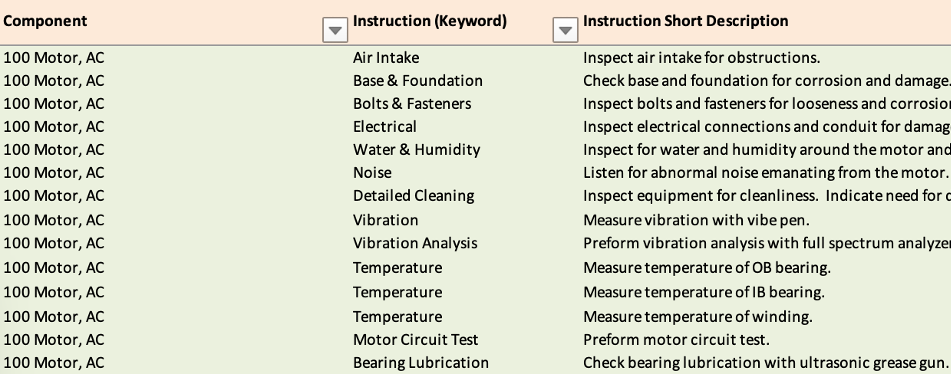

In the database you will find fields for Component, Keyword, Short Description (shown above) as well as Inspection Result Options, Equipment State, Minimum and Maximum Recommended Measurement, etc. The database also includes information on who should perform the Preventive Maintenance tasks and how often they should be done.

The information in Figure 2 demonstrates a typical inspection, but the procedure can change based on where the motor is located (in a wet or dry place for example), the RPM, the load, etc.

When we have this information in a spreadsheet in a database format, it needs to be exported to the Computerized Maintenance Management System (CMMS) and the tasks need to be divided into lube route software, vibration software, etc.

Using Condition Monitoring Standards (CMS)

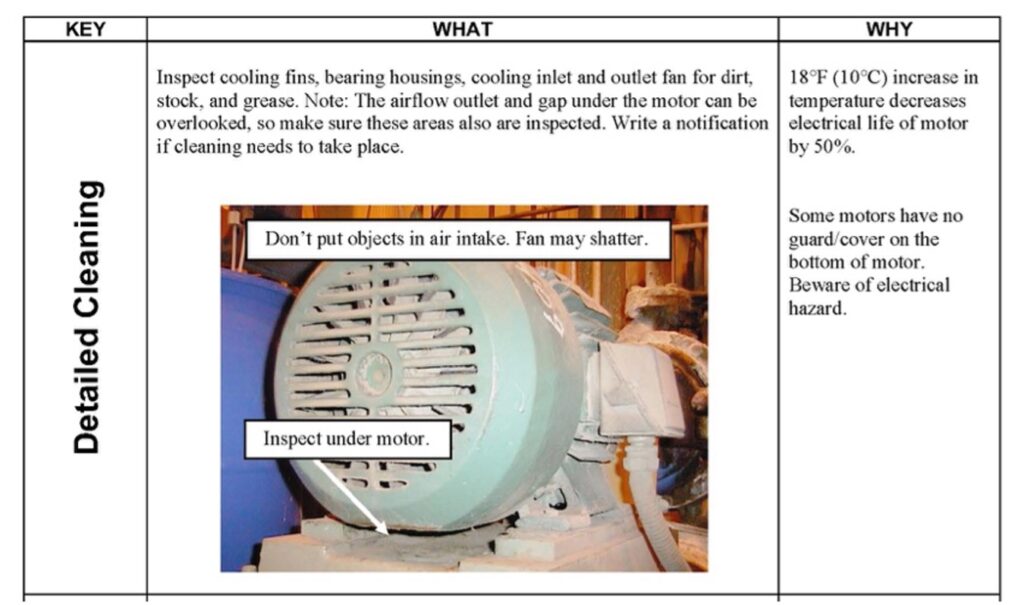

In Figure 2 above, you will see that one of the keywords on the list is “Detailed Cleaning.”

Figure 3 shows IDCON’s Condition Monitoring Standard (CMS) for Detailed Cleaning of an AC Motor. Get your copy of the complete Condition Monitoring Standards today.

In the first of the three columns is the keyword matching to the database. The next column is “What” and contains a short but detailed description of the task that needs to be performed for the keyword. In the third column “Why” there is an explanation of why the task needs to be performed.

Using the Condition Monitoring Standards (CMS) is part of the Know-Why training that IDCON has stood by for years.

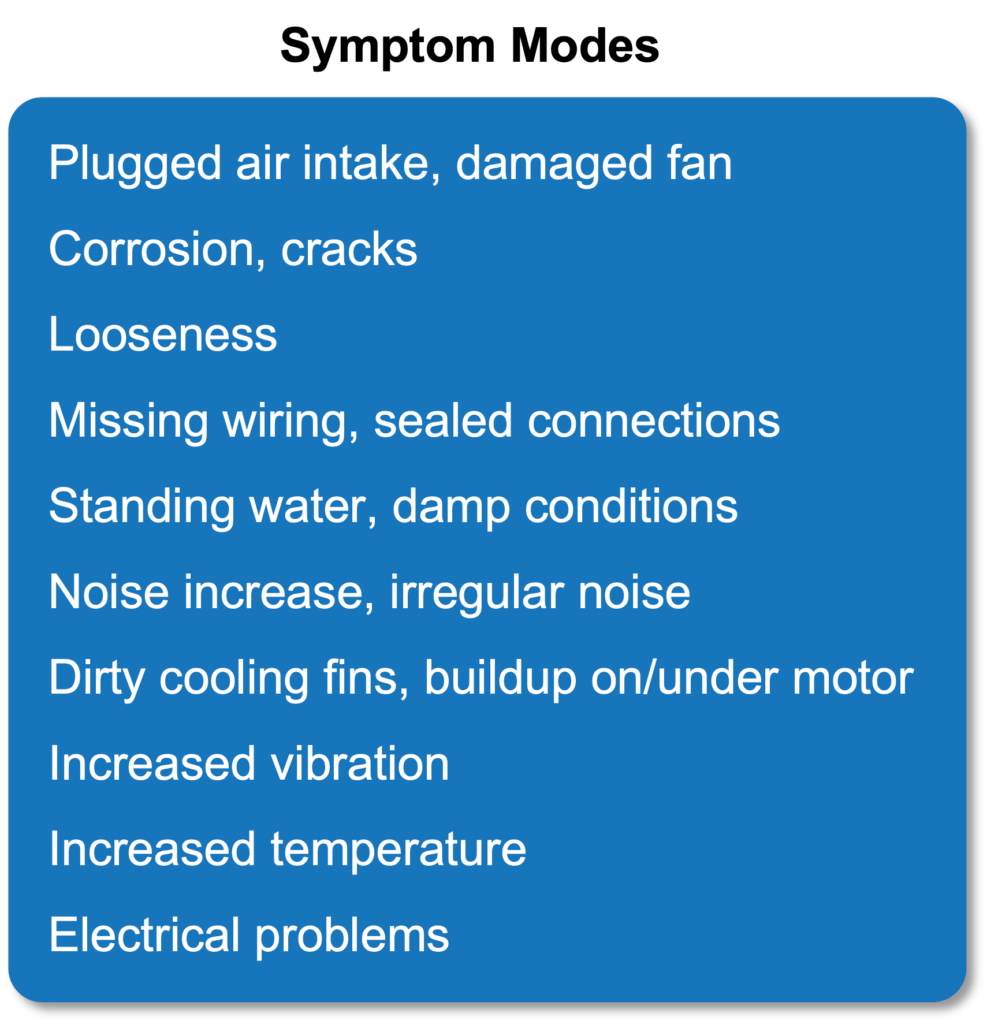

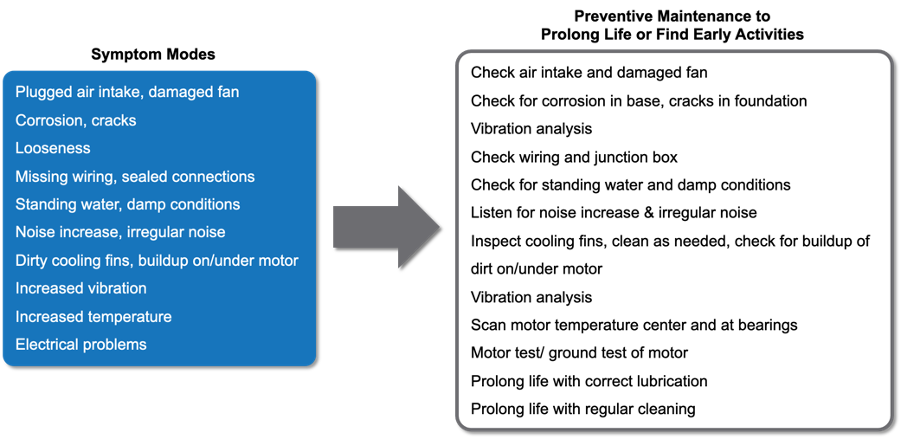

Symptom Modes

If you are not using the CMS, we find that it is useful to look at the symptom modes on the equipment or component rather than the failure modes. The symptom modes are what can actually be detected on the equipment. See Figure 4 below.

Symptom modes can be detected, but failure modes cannot. For example, “corrosion on the bearing of the motor” is a specific failure mode that can’t be detected with basic inspections. Vibration analysis can detect that there is damage in the bearing, but it is not possible to discern that the damage is corrosion from vibration analysis alone. Find out the best way to check bearings here!

Therefore, the symptom mode would be “damaged bearing.” A Root Cause Failure Analysis including disassembly would have to be performed to find the failure mode “corrosion on bearing.”

Preventing Failure, Prolonging Life, and Finding Failures Early

Once you have the symptom modes, it is time to figure out if there is anything that can be done to prevent the failure from happening.

Figure 6 shows a list of actions to take to prevent failures (or prolong life). Some of these actions are included in your Preventive Maintenance Program, such as regular cleaning of the motor, checking airflow, lubrication. There are also tasks outside of the PM Program that can be done, such as correct installation and alignment, balancing of shafts, proper torque, etc.

These are actions that can be taken to prevent the failure from happening, but what about finding failures early? Use the symptom modes, for example, “increased temperature” to help come up with tasks such as checking the temperature of bearings and the center of the motor that will tell you if PM needs to be performed on a piece of equipment or component.

All of these symptom modes and Preventive Maintenance actions can be combined to create a standard that can be used for an AC motor, and the same process of gathering information and deciding on PM actions can be applied to any equipment or component in the plant. Then it can be customized based on the specific conditions of the equipment in your plant, mill, or mine.

Look out for Part 10, the final installment in this series, coming up soon. It will cover the best way to assign tasks and tools to your team when documenting cost-effective Preventive Maintenance systems in your organization.

To watch the video accompanying this article, click here, and don’t forget to subscribe to our YouTube channel while you’re there!

Torbjörn Idhammar is president and CEO of IDCON, Inc. and section editor of Reliability & Maintenance for Paper360° magazine. Contact him at [email protected]. For more articles, please visit: www.idcon.comand https://maintenanceworld.com.

Paper 360

Paper 360