Planning is an extremely important link in the maintenance chain: "Inspect—prioritize—plan—schedule—execute."

Read More »Reliability and Maintenance

Reach the Perfect Temperature with Regular Heating System Maintenance

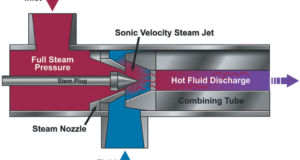

CLARK CONLEY Green liquor heaters make the slaking process run better in kraft mill applications. However, green liquor is very demanding on the heater. Annual inspection and maintenance of your heating systems ensure that your green liquor stays at the optimum temperature. Exact temperature management in the kraft mill process is critical for conversion efficiency in recausticizing green liquor ...

Read More »Reliability and Safety

Leveraging reliability improvements to reduce overall risk.

Read More »R&M TIP: MOTORS

IR Inspections of Electric Motors

Read More »Reliability and Safety

Part 1: The Link Between Personnel Safety and Equipment Reliability

Read More »How China Came to Dominate Market for Lithium Batteries

China's share of the battery market has increased dramatically, from 60 percent in 2018 to 72 percent in 2020.

Read More »It Turned into Nothing

The product of maintenance work should not be service. It is not repair and it is not cost. The outcome of maintenance work is equipment reliability.

Read More »Reliability Engineers – what is their role at your mill?

by Christer Idhammar, Founder IDCON, Inc. – helping mills become world class maintenance organizations During a recent reliability and maintenance conference, we met several Reliability Engineers telling us they found their job different from what they expected it to be. Many of them had graduated as reliability engineers and had learned all about Mean Time To Repair (MTTR), Mean Time ...

Read More »Dissimilar Metal Corrosion – what’s the impact?

by Owe Forsberg, Vice President IDCON, Inc. – helping mills to become world class maintenance organizations. Here’s a real-life root cause analysis (RCA) for you to think about. A trailer was repaired after the side was scraped. The bolts that held the cross members to the aluminum frame on the side were replaced. The trailer passed the DOT inspection. One ...

Read More »Should Maintenance Cost be Benchmarked?

TOR IDHAMMAR Trying to benchmark maintenance cost is a very common practice among many plants or companies. The maintenance cost/ton or maintenance cost/unit is usually considered the most important benchmark. However, only focusing on the maintenance cost/unit benchmarking is not useful. Why not? First, comparing maintenance cost between plants is very difficult because of variables such as the organization’s definition ...

Read More » Paper 360

Paper 360