How to Document Cost Effective Maintenance Tasks: Part 8

Torbjörn Idhammar, President, IDCON INC

Part 7 “Choosing a Maintenance Method” detailed the three maintenance methods to choose from when performing Preventive Maintenance on equipment or components, and how to select the most cost-effective one. After choosing a maintenance method, it is time to organize the Preventive Maintenance tasks.

Add Content to Preventive Maintenance Tasks

When adding content to your Preventive Maintenance tasks, start with collecting the existing PMs for the equipment as well as any applicable vendor information. Vendor’s equipment manuals can offer useful information as well when selecting PM tasks, but often the manuals don’t tell the full story. For example, a manual for a centrifugal pump will say “run it at the best efficiency point and lubricate” when we know there is much more to the pump and its maintenance than that.

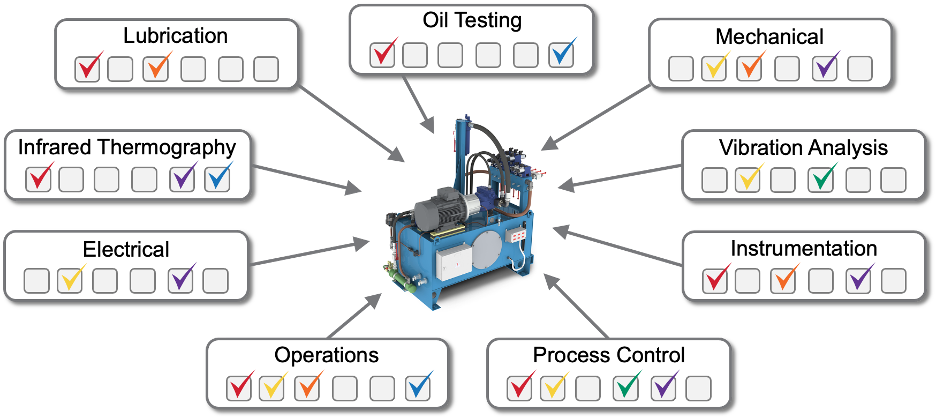

When it comes to existing PMs, the first thought is usually to search in the Computerized Maintenance Management System (CMMS). Of course, this is a valuable resource, but we may be missing other activity happening in departments of the plant, mill, or mine. It is very common that different crafts/departments have set up their own Preventive Maintenance Systems for components and equipment. (This is why communication is key!) See the example below using a simple hydraulic unit:

As you can see in Image 1, crafts, trades, and departments ranging from Lubrication to Process Control have set up PMs and/or inspections for the components of this hydraulic unit.

Determine the Right Preventive Maintenance Tasks

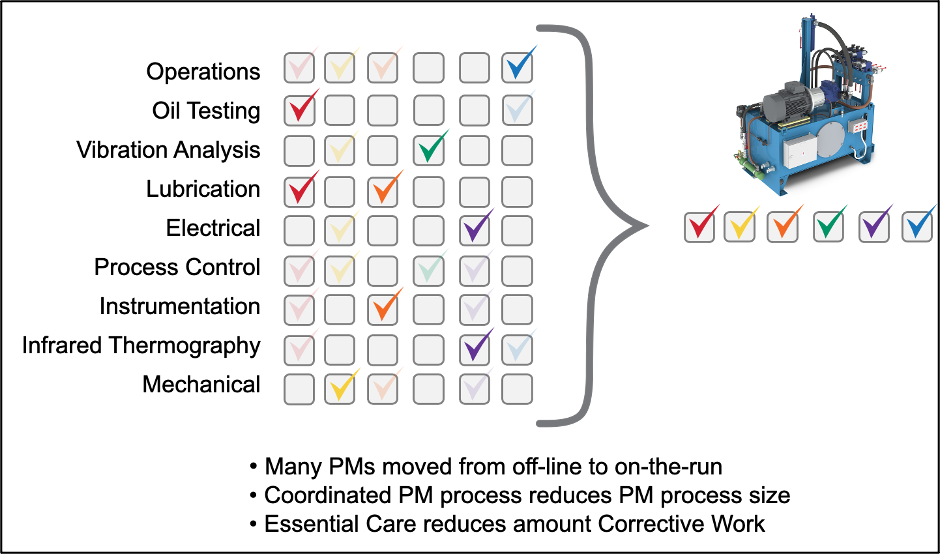

All the PMs that the different craft departments have added need to be organized and duplicates need to be eliminated. Instead of focusing on the needs of the crafts, it is better to determine the needs of the equipment itself. Image 2 below shows an organized selection of the Preventive Maintenance tasks ordered by the departments based on what the actual piece of equipment requires.

Once the necessary PMs are selected for the equipment, you can determine which tools are needed, which person should perform which task, when the task should be performed, etc. (Maintenance Planning and Scheduling).

To watch the video accompanying this article, click here and don’t forget to subscribe to our YouTube channel while you’re there!

Torbjörn Idhammar is president and CEO of IDCON, Inc. and section editor of Reliability & Maintenance for Paper360° magazine. Contact him at [email protected]. For more articles, please visit: www.idcon.comand https://maintenanceworld.com.

Paper 360

Paper 360