Don’t have time to read? Watch the YouTube Video.

A key inspection for gear reducers is to listen for noise. The inspection should focus on a change in the sound. Use a stethoscope, if necessary. Don’t have a stethoscope? You can use a wooden stick to listen for noise.

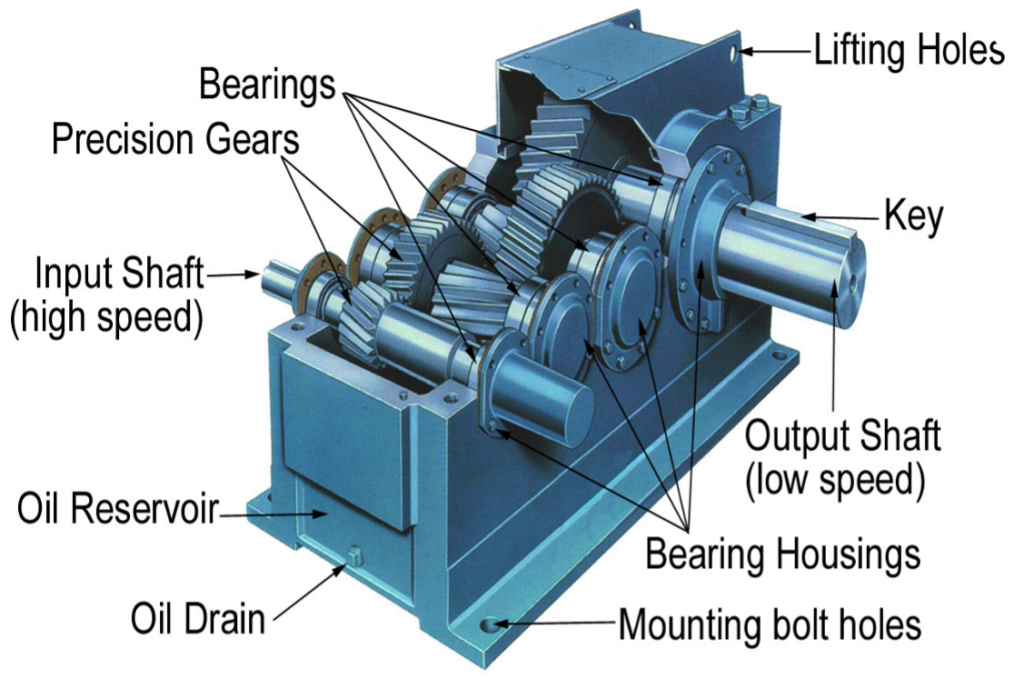

Excessive noise can point to misalignment, poor lubrication, worn/failed bearings, worn/damaged gear teeth.

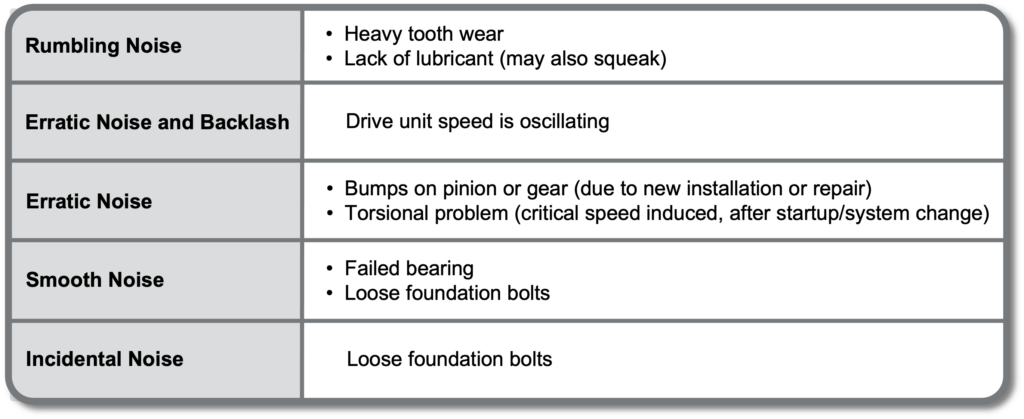

Interpreting noises:

How to determine/fix:

- Check the gear teeth on shutdown (rumbling)

- Change/refill lubricant (rumbling or squeaky)

- Check gears next shutdown (erratic noise & backlash)

- Disconnect the output coupling and run drive, if noise changes or disappears, system is the cause (erratic noise & backlash)

- Take unit apart on shutdown, check for shiny spots on gear. (erratic noise)

- Make mechanical blue imprint (erratic noise)

- Check gear clearance with lead or plastic wire (erratic noise)

- Consult system expert (Torsional problem)

- Check axial float (smooth)

- Tighten bolts, check foundation condition (smooth or incidental)

Even though the gear reducer is making noise, be sure the condition isn’t caused from other system problems, such as fluctuation in drive speed or coupling wear.

For more on how to inspect and care for the Gear Reducer, purchase IDCON’s Condition Monitoring Standard Volume 1.

IDCON INC will release Volume 5 of our Condition Monitoring Standards soon – keep an eye out!

Paper 360

Paper 360