Sustana is a leading producer of top-quality fiber-based products and services, committed to sustainability and continuous improvement. Operating across North America with nine recovery facilities, two fiber recycling facilities, and a paper manufacturing facility, Sustana is a trailblazer in incorporating clean, renewable materials into everyday products.

Sustana manufactures premium, FSC® certified sustainable recycled fiber ideal for a range of applications. From food-grade packaging to printing and commercial paper and board, plus towel and tissue paper, their products embody both performance and environmental stewardship. Within their facilities in De Pere, WI, and Levis, QC, Canada, Sustana processes up to 2.2 million pounds per day of recovered paper in the form of sorted office paper, paper cups, aseptic and gable top cartons, and even release liner. This translates to a significant reduction in landfill space—over one million cubic yards per year. (See sidebar to read more about Sustana’s sustainability commitment.)

The De Pere facility, established in 1992, has specialized in wet lap fiber production. While producing 450 tons per day of quality fiber, the mill’s growth potential remained restricted due to manufacturing and transportation challenges of a product that was roughly 50 percent water. The answer? A capital project with a unique equipment source, making the most of every opportunity. The addition of dryer equipment at this facility marks a pivotal move to propel production into a new era within the recycled fiber market.

Sustana’s wet lap pulp already has a unique market: sustainable, 100 percent recycled fiber that is compliant with FDA standards for use in direct food contact packaging without the need for a barrier of any type. However, shipping wet lap is not economical, and in wet form the pulp has a limited shelf life. This project allowed Sustana to produce dry baled pulp that can be stored indefinitely and shipped anywhere in the world.

Sustana acquired the fluff drying equipment from Chetwynd, British Columbia, in September 2022. The Chetwynd mill had undergone a two-week shutdown in 2015, during which the decision was made to close the facility. At the time of closure, the drying system and presses were undergoing reconstruction and were at various stages of repair. The equipment remained disassembled and idle until Sustana stepped in to acquire it. Now, it stands as a testament to resilience and adaptability, ready to drive the De Pere operations forward.

A NEW PROCESS FLOW

Sustana has been producing wet lap for more than 30 years. With the installation of the new pulp drying and bale system, the mill bypasses the sheeting section of the wet lap machine. The web is fed to a shredding and screw conveyor, making it easier to transport to the dryer system. The pulp is then transferred via belt conveyors to a fluffer, which is very similar to a deflaker—not doing any fibrillation of the fibers but taking small chunks of pulp and increasing the surface area into a cotton candy fluff texture for more efficient drying. The pulp is then directly fed into two 130-foot vertical dryer stages.

The heat source for the dryer is two identical natural gas burners, supplied by Andritz. This is a modification of the Chetwynd design, which used steam coils. Each section of the 130-ft. drying tower is followed by a cyclone to remove moisture from the dry pulp. Exhaust from the second stage is used to preheat the first stage combustion air for increased efficiency. Dry fiber from the discharge of the secondary cyclone is fed into the tertiary stage where the fiber is cooled prior to being pressed into a bale at the slab press.

The slab press makes a compact bale out of the fluff that is sent to it, creating a 500 lb. bale that is 24″ × 36″ at 90 percent solids. At this point, the bale is very hard and compact, but a final pressing stage removes any further entrapped air in the pulp to prevent growth, reducing the final height of the bale to 20″. From here, the bales are wrapped, strapped, stacked, and ready for final shipment.

SPECIALISTS FOR SUCCESSFUL INSTALLATION

This project was extremely fast paced, with the equipment being removed from Chetwynd at the same time the new layout and design was being developed for the new site conditions in De Pere. A significant challenge this project faced was that it was not new equipment purchased through an OEM. There was no central technical knowledge of how this system should be installed, controlled, or operated. Consequently, the project team systematically sought out specialists in each of the functional areas to help with installation and startup. This effort was led by Precision Industrial Contractors, Woodland, WA, which served as the project lead for engineering and installation.

The control system that came with the equipment required a specialist to assist with the set-up. Brian Woodley, a controls engineer who operates Innotech Industrial Innovations, brought a unique background to the project as he was a pulp line operator at Chetwynd prior to becoming a controls engineer. This experience proved to be invaluable to the project team as the equipment came without documentation. Woodley was able to re-create and improve the original control scheme from the slab press through the final conveyor.

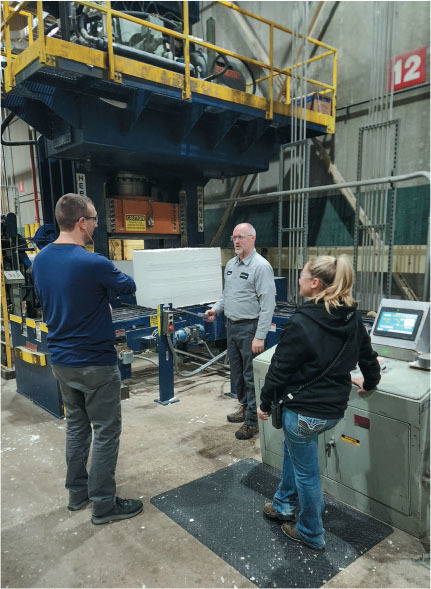

The hydraulics and control of the hydraulic systems are critical in the operation and control of both bale presses. Sustana brought in two individuals to assist with this portion of the project, one for each of the presses. Brian Menzies from Brian M Hydraulics LTD focused on the bale press, and Phil Jones of Legacy Automation, Inc. worked on the Hepburn press.

Menzies, a millwright by trade, has worked with bale presses for many years at a mill in British Columbia. He quickly became an expert in the operation, troubleshooting, and maintenance of such presses. Menzies subsequently started his own consulting business and now works throughout Canada and the US assisting on complicated hydraulic processes, with a focus on bale presses for fiber systems. Menzies was instrumental in the success of this project, as he provided guidance and training for the complex slab press.

Jones has overseen the installation and operations of dozens of Hepburn presses over the course of his career. He focuses on servicing and maintaining Hepburn presses throughout the US and overseas.

BALANCE OF POWER

One major hurdle on this project was the power distribution required for the equipment. In Chetwynd, the standard power is distributed at 575V, while a nominal 480V line voltage is used in the United States. To keep within the project’s tight timeframe, Sustana needed a new power distribution system for the bale line equipment, independent of the current facility power distribution system. This involved working closely with the local power provider, Wisconsin Public Service (WPS), to install new local transformers and an exterior high-voltage junction box to accommodate the power and voltage requirements.

Taking into consideration the age and condition of the equipment that was being relocated from Chetwynd to De Pere, the team evaluated and systematically pulled out critical components and major equipment to be evaluated and rebuilt locally. This equipment consisted of the 4160 switchgear, 575V MCCs, hydraulic pumps for both presses, medium and low voltage motors, instrumentation, valving, and hydraulic hoses and piping. Local major partners included, but were not limited to, Astro Hydraulics, JAMAR, GreCon, Coenen Mechanical, L&S Electric, Pearl Engineering, and Miron Construction.

SUSTANA MILL OPERATIONS

The project’s success is also due to the workforce at Sustana De Pere. The mill’s workforce culture—characterized by teamwork and collaboration—has been instilled since the mill’s inception in 1992. The establishment of a four-team structure is set up for cross training on every job, and over the mill’s 30 years, numerous production improvement ideas have been generated from the hourly teams. As a testament to the continuous improvement mindset, the wet lap machine that is still running in De Pere has more than doubled its original designed throughput.

Once the dryer equipment was turned over to production, the startup curve was steep. The first bale was made on September 21, 2023, and the team had the system running continuously by November 7, 2023, producing top-quality pulp.

“While there was a benefit to having contractors onsite that were equipment experts, a major part of the quick startup is a direct reflection of how engaged and special this workforce is,” says Dan Bassindale, plant manager in De Pere. “I cannot express enough how quickly this group took ownership of this equipment and drove the startup process. It is a pleasure to work with them every day.”

The De Pere mill’s workforce is not the only remarkable part of this optimization project. A few more interesting facts include:

- In the pulp and paper industry, it is common for equipment to be removed from plants in the United States and sent out of the country, but with Sustana it was just the opposite: equipment was brought back into the US to find new purpose.

- The workforce and dedication required to pull off this project within the one-year timeframe required assistance from individuals across the US, Canada, and Europe. The workforce spanned labor staff as young as 22, to machine designers who originally designed this equipment who are now nearly 78 years old. One millwright noted that his father had installed this same equipment in British Columbia when it was purchased new, and now he was able to remove, reinstall, and start the equipment up in Wisconsin, giving the equipment new life in a new country.

- The project also optimizes customer choice between wet lap or dry bale pulp that is recycled and FDA-approved.

- The dry baled pulp exhibits great characteristics for the end user. Because of its bulk density and dryness, when the bale is dropped in the pulper, the bale acts as a sponge and absorbs water very quickly; it falls apart with very little mechanical action required. Although in its final bale form it is hard as concrete, within 30 seconds in a pulper it will become a slurry.

The journey from equipment purchase to startup extended over the course of one year, presenting both challenges and achievements. Had Sustana opted for new equipment, delivery and installation would have likely commenced in early 2024, without factoring in the necessary infrastructure construction. However, by acquiring used equipment, the company gained a significant advantage: salable product delivery occurred at least two years earlier than the timeline for procuring new equipment.

Dan Goymerac, Miron Construction, served as Sustana representative, construction and engineering on the project. He sums things up as follows: “The dedication of the project team and the numerous local, multi-state, and international project partners, along with the equipment experts who assisted with this project, are a testament to the pulp and paper industry as a whole, and to the client’s commitment to making this project a success.”

Paper 360

Paper 360