CHRISTER IDHAMMAR

IDCON, INC. FOUNDER AND RECOGNIZED RM GURU

Belief XIV: Always explain what, why, and how.

People do not mind change, but they do not like to be changed (Belief VII). Any improvement initiative requires a sales pitch. You need to have a clear vision of what the improvement initiative entails and why it is necessary to do it. You might have a clear idea of how it is going to be done, but after explaining the “what” and the “why,” it is effective to ask the people involved to come up with ideas on how they think it could be done. Focus first on reaching a consensus on “the right things to do” and then discuss how to do them. You will find that it is much easier for people to agree on the right things to do than on how they should be done.

Many organizations put too much emphasis on change management and end up complicating this concept. We often hear “we already do this,” which may very well be true—most organizations do most of the elements of best reliability and maintenance practices—but most can do these elements much better.

Of course, there might still be an element of change for some people, but like most of the improvements we talk about here, this is common sense and nothing new. Change management elements should be included, but not overdone.

It can also help to establish a definition of “what good looks like” and determine desired outcomes for the future. Here are some examples:

• Production reliability is improved by 3%

• Maintenance cost is down by 15%

• Very few maintenance people are on late shift (24/7 operation)

• Majority of basic equipment is maintained by trained operators

Belief XV: Execution is key to success.

The elements of a maintenance management system have not changed much since the 1960s. Technology such as computerized maintenance management systems and predictive maintenance tools have changed dramatically and are now much better and much more affordable. Since the 1970s, industries have moved away from fixed-time overhauls and replacements of equipment components to focusing more on condition-based maintenance.

It should be obvious that an improvement plan is meant to be executed, but nevertheless, many plans are never implemented to completion before a new initiative starts. I have seen so many excellent plans and presentations followed by failure to act on them.

As demonstrated in Fig. 1, the time it takes to develop a best practices document, define roles, educate the crew, and agree on a common repeatable assessment methodology and strategy might be 5 percent of the total effort. Getting acceptance from those responsible for implementation might be 10 percent of total effort. The remaining 85 percent should be on-the-job training and coaching. Too often, the time is spent more on development, etc. and almost no time is spent on supporting execution through on-the-job training and coaching.

The only major difference I have seen between the best performers and the lagging organizations is that the best performers execute well-defined best practices. Like I said before, most organizations know what they need to do, they just don’t consistently execute and continuously improve the best practices.

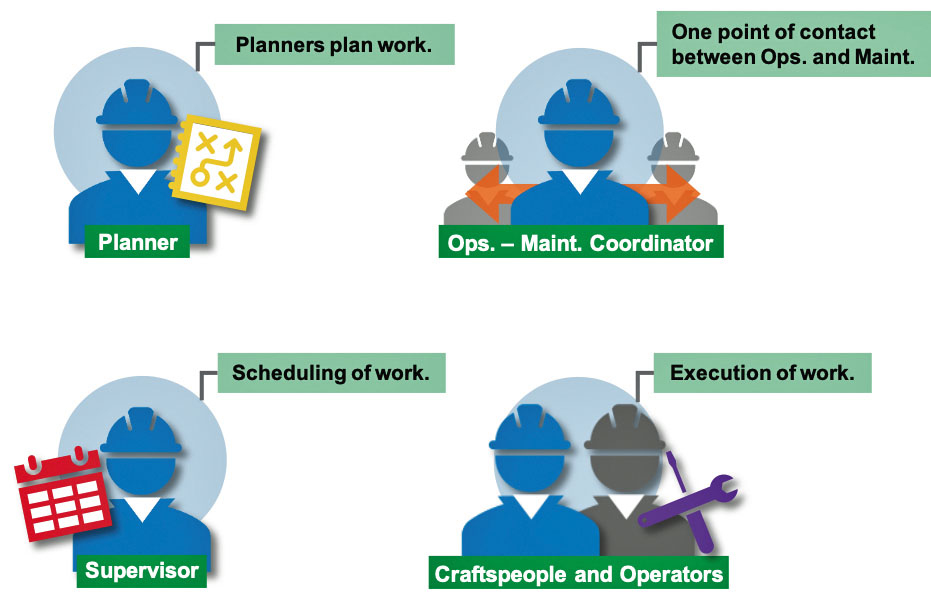

In an effective organization (see Fig. 2), there needs to be a function that collects and filters incoming work requests. There needs to be one established “point of contact,” or coordinator, between Operations and Maintenance. Planning needs to be done by someone (often a Planner) before work is scheduled for execution. Scheduling of work is often done by a frontline work leader or supervisor.

Who will execute? A notice to all managers: Every improvement initiative must be executed by the frontline organization—the craftspeople and operators. If the frontline organization does not perform, no benefits will result from the process.

Excellent, consistent, long-term leadership with well-defined, well-documented processes, and having the right people in the right positions, are the most essential factors for successfully executing and benefitting from any category of improvement initiative an organization undertakes.

Now that we have explored the details of the different beliefs, I want to remind you of the reason why they were created:

In a leadership role you need to create an organization of followers that will help make your vision, or future organization, a reality. As a leader myself, I have found it very important to develop and communicate my beliefs to the organization. These beliefs will guide your team on their journey toward accomplishing goals.

It’s as simple as that. Through establishing beliefs that cover essential elements, you can create the culture focused on proper planning, scheduling, and execution that all successful organizations have.

Christer Idhammar operates by a set of beliefs developed from his time spent in various R&M positions over a 60-year career. His wide range of experience includes working onboard ships in engine rooms and later mostly in process industries including food, pulp and paper, iron and steel, chemical, mining, and auto manufacturing. He discovered very early on that reliability and maintenance management is much more about good management and strong leadership than technology.

Paper 360

Paper 360