Perhaps no event in recent memory has affected so many globally as the COVID-19 coronavirus. Of course, the pulp and paper industry is no exception. Many governments have recognized the industry as being essential in these difficult times and thus, allowed to continue to operate.

To mark this strange and uncertain time for our industry—and to spotlight the extraordinary efforts of our industry’s leaders and innovators—the Paper360° editorial team has gathered news from companies in our industry responding to the crisis in admirable ways. Some have adapted their production capabilities to meet sudden changes in global demand for products used by citizens and health care workers to support health and safety. Others explored new collaborations to serve their communities or invent new solutions.

By the time this issue has reached your desk, laptop, or mobile device, you may know of even more ways that our manufacturers, suppliers, and industry organizations are responding to this global pandemic. We encourage you to share your stories on TAPPI Connect at www.tappi.org.

The following snippets are but a few examples of how the industry has faced the virus and what it is doing to aid global efforts to combat COVID-19.

PRODUCERS

DS Smith has worked closely with food retailers across Europe to design, develop and produce new boxes designed to supply emergency provision boxes to the most vulnerable. The company’s Packaging CEO, Stefano Rossi, said the solution allows for a “stack, drop and go approach that is more time efficient, more hygienic and frees up time for more deliveries.”

Pulp producer Harmac Pacific in British Columbia produces K10S pulp that is used to make disposable surgical masks, hospitals gowns, and other medical supplies. A US firm that makes medical supplies recently doubled its order from Harmac Pacific.

Pratt and Visy Industries global chairman Anthony Pratt has donated US$1 million to fund testing in Australia of two medications that might be a vaccine for or help COVID-19 patients.

Mondi’s plant in Gronau, Germany, typically focuses on making materials for hygiene products; however, the plant was able to quickly adapt one of its manufacturing lines to produce a three-layer, laminated strap that binds a stretchable plastic film between layers of soft, nonwoven material. The straps, which Mondi supplies to its mask-making customers on a reel, are then cut and attached to each side of a face mask. This elastic material replaces a rubberized band, thereby increasing operational speed of the machines in comparison to rubber.

Georgia-Pacific issued a very interesting statement about how much toilet paper people need. “The average US household uses 409 equivalized regular rolls per year. Using our own calculations, staying at home 24/7 would result in a 40 percent increase versus average daily usage. Therefore, to last approximately two weeks, a 2-person household would need nine double rolls or five mega rolls. A four-person household would need 17 double rolls or 9 mega rolls to last approximately two weeks.”

All tissue producers, cognizant of the run on tissue during the pandemic, have said their facilities are running full out to meet demand. As G-P explained: “While the timing (stocking store shelves) is uncertain due to many variables in the supply chain process, our primary focus is to do all we can to meet consumer demand.”

In an interview with The Montreal Gazette’s Bill Brownstein, Kruger Products CEO Dino Bianco also addressed the toilet paper problem. “Grocery stores don’t carry that much toilet paper in its designated sections because it takes up lots of space. So the shelves are fast emptied. And as soon as you see an empty shelf, your mind says supplies are running out and you’d better buy more. Then pictures start going around the Internet and panic sets in that there’s a shortage. Toilet paper is a very emotive item.”

Procter & Gamble said it was manufacturing masks at almost a dozen of its sites globally. It has also established a new line to produce hand sanitizer. When fully operational at five sites globally, it will be able to produce 45,000 L/week. In Europe, the company has donated US$10 million in goods and financial support.

In South Africa, the industry will continue to operate as a “critical business continuity service,” according to the Paper Manufacturers Association of South Africa (PAMSA). Its executive director, Jane Molony, said, “Never before has toilet paper enjoyed such publicity. Any perceived shortage of toilet paper in the shops is more a consumer behavioral issue that it is a production issue.” She also noted, and this can be applied to almost any region in the world, that there is availability of product further up the supply chain, but the challenge is getting it to the consumer amid manufacturers trying to limit COVID-19 exposure for their own workers.

Virtually all producers’ websites have information about what each company is doing to provide the best possible service during this crisis and many have released statements. The following from International Paper is typical. “Protecting the health and safety of our employees and contractors is our most important responsibility. We will continue to operate our mills and converting plants while practicing personal hygiene, social distancing, site cleaning and other measures recommended by the World Health Organization and the Centers for Disease Control and Prevention.”

As of press time, many mills have been shut either due to:

• Market conditions: For example, Chinese coated fine paper producers APP, Shandong Huatai, Shandong Sun Paper, Shandong Chenming have announced large amounts of downtime in April. Rayonier has ceased production of newsprint at its mill in Kapuskasing, ON (Canada). Kruger has closed its Brompton, QC,paper mill.

• COVID-19 afflicting workers: Norske Skog Golbey PM 2 (France); Arauco Horcones (Chile). Columbia Pulp temporarily shut down its Lyons Ferry, WA, facility. Mercer International Inc. will be taking approximately four weeks of downtime (starting April 20) at its joint venture Cariboo pulp mill. Domtar Corporation will temporarily idle its Kingsport, TN, mill and the A62 paper machine at its Ashdown, AK, mill for three months.

Many expansion projects in Latin America have been put on hold. Companies affected include: Klabin, UPM, WestRock and Arauco.

In New Zealand, the government ordered the closure of all non-essential businesses for four weeks (as of press time in early April.) This included market pulp mills operated by Winstone Pulp International, Pan Pac Forest Products and Oji Fiber Solutions. It should be noted that not all mills in the country are down. For example, Oji’s Kinleith mill is still up. The only tissue mill in New Zealand, owned by Asaleo Care, is operating.

France has extended confinement measures in the country, but most paper and board mills are running. The association of French paper industries, Copacel, said seven small mills have shut and 20 others have reduced operations due to a shortage of workers.

The Indian pulp and paper industry is mostly in lockdown, although exemptions are available. Among the companies announcing closures are: JK Paper, ITC and Ballarpur. However, Paswara Papers has announced it will continue to operate. Logistical issues also plague the country as many truckers are not working or unable to do so. An April 3 report of a study from Shiv Nadar University estimated that India could have witnessed a surge of 31,000 cases of disease between March 24 and April 14 without lockdown.

The Bureau of International Recycling (BIR), has called upon governments to recognize recycling industries as essential services. “Recycling operations are providing secondary raw materials, critical to downstream industries, some of them directly involved in combating the COVID-19 pandemic.”

SUPPLIERS

Arkema Group, a supplier of coating and bleaching products for the pulp and paper industry, has repurposed a production line in order to manufacture 20 tons of alcohol-based solution per week to be distributed free of charge to hospitals in France. A pilot line at the company’s Rhône Alpes Research Center (CRRA), near Lyon, was dedicated to the manufacture of the alcohol-based solution, which will be supplied to the French health authorities and earmarked in particular for the mass restocking of public hospitals.

Ecolab has been closely tracking the coronavirus since February, and has compiled resources to help hospitals, restaurants, and the hospitality industry deal with the special cleaning demands of fighting the virus. A link from ecolab.com helps customers find the guidelines and reports on how Ecolab is responding for its own workers.

Siemens has put in place a global and US-specific task force to continuously monitor the impact of COVID-19. According to the company, areas include:

• Healthcare infrastructure: The company’s cloud-based platforms for remote monitoring and climate control are helping facilities meet the air-pressurization requirements necessary to prevent further transmission of COVID-19.

• Medical equipment for patient testing and care, including technology for blood-gas monitoring for patients on ventilator support, portable X-ray systems for triage areas, ultrasound systems for bedside assessment, and CT systems for acute cases.

• Increasing manufacturing capacity to address supply shortages and enable manufacturers to switch production lines to pharma or medical devices and expedite the production of personal protective equipment such as masks. Siemens has also made its 3D-printing network available at no cost to designers and suppliers providing critical medical supplies.

HP Inc. has mobilized its 3D printing capabilities to help deliver critical medical equipment parts; by mid-March, more than 1,000 3D printed parts had been delivered to local hospitals. HP’s 3D R&D centers in Barcelona, Spain; Corvallis, OR; San Diego, CA; and Vancouver, WA, planned to increase production to meet the most urgent needs. Initial applications being validated and finalized for industrial production include face masks, face shields, mask adjusters, nasal swabs, hands-free door openers, and respirator parts.

The German company Wrapping Solutions, which specializes in producing interior fittings for cars, decided to produce mouth and nose protection masks. Since mid-March, up to 24,000 masks per day were being sewn at 20 workplaces, with plans to expand to 40 sewing workstations. When a production bottleneck was identified, packaging machinery provider Optima designed a custom device for folding the face masks (see photo).

FROM THE ANALYSTS

KeyBanc Capital Markets says the pandemic will be “problematic” for the graphic paper market as people are working and studying from home and not attending conferences. This compounds the decline that has already been seen in demand over the past few years. Pulp can also see a decline because of the aforementioned decline in P&W markets as well as being tied to global economic activity.

FastmarketsRISI notes that tissue and packaging are two sectors that have run contrary to decline in demand in other sectors. However, this was due to panic buying of tissue leading to huge demands on the supply chain as well as increased demand for home delivery of goods. If things ease, this could result in lower demand in the latter part of the year. AfH tissue could be particularly hit hard as restaurants close, travel is curtailed and people stay home. As the Viewpoint points out, “The economic disruptions emanating from the social upheaval the pandemic has placed on the world will be severe and will ripple through all industries.”

Moody’s Investor Services predicts COVID-19 will pressure demand and drive prices lower. “The global economic outlook is deteriorating as the outbreak spreads… the impact on global demand will likely be far worse than on global production. This will result in oversupply in many regions, which will drive prices for most grades lower.”

From Trade Show to Hospital

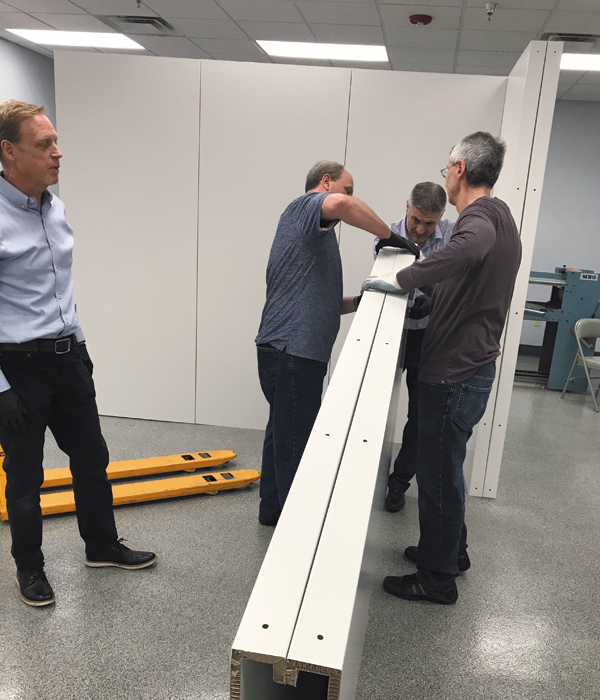

Mohawk Paper, along with a South African startup, Xanita Board, for which Mohawk acts as a distributor in North America, have done something well out of the ordinary. The board, usually sold to construct exhibits at trade shows has, thanks to an idea from Mohawk, been adapted to create pop-up field hospital rooms. All of the board now at Mohawk can be converted quickly into walls, beds, and other structures.

“Now is not the time to hold back knowledge that could help protect our communities from this crisis,” said VP of Product Development Mike Madura. “For our merchants who have Xanita in stock, they’ll be able to easily offer these field hospital kits to their communities. And for any creative minds who want to help, we hope it will provide a foundation on which they can build their ideas.”

Paper 360

Paper 360