BEN THORP, HARRY SEAMANS, AND MASOOD AKHTAR

According to the Bureau of Labor Statistics (BLS) there were 17,619,000 Americans employed in the manufacturing section in January 1998; by January 2010, this figure had declined to 11,462,000, or a loss of 6,157,000 factory jobs in 12 years (Hemphill et al. 2015). This does not count the number of “consequential” jobs that were also lost. This loss of manufacturing jobs has reached the point of creating national concern.

There is a need for socio-economic actions to efficiently maintain and create jobs. These days we often hear the comment “Innovation is the key to creating more jobs.” We agree, but changes must be made to make it more effective in our more global US society. Similar situations are being faced by many developed nations, but our research focuses on the US.

Restoring manufacturing jobs will be difficult because the manufacturing industry is trying to use research and innovation to overcome national policy that has put the US in an unbalanced position in the world. Our analysis required extensive investigation of the real role of manufacturing jobs in an economy, and of the complex and ever-changing trade policies that are thousands of pages long and periodically amended.

Today we live in a more global, less national society where more companies are international, and if a company is not yet international it will likely compete with those who are. US policies established over the last several decades have helped force the international production of goods we buy. The policies favor low cost products—which is fine and good when the trade playing field is level—but due to an unlevel playing field, we feel this has led to the loss of US manufacturing jobs. This favor toward low cost has weakened the normal result of innovation on creating jobs.

Today we live in a more global, less national society where more companies are international, and if a company is not yet international it will likely compete with those who are. US policies established over the last several decades have helped force the international production of goods we buy. The policies favor low cost products—which is fine and good when the trade playing field is level—but due to an unlevel playing field, we feel this has led to the loss of US manufacturing jobs. This favor toward low cost has weakened the normal result of innovation on creating jobs.

Citizens ask, “What happened to the good manufacturing jobs and the communities they once supported?” One answer given frequently and far too casually is that America is the country of great innovation, and we will invent things that will create new and even better jobs. The fallacy of that notion creates a tremendous challenge.

To illustrate this point, let’s examine the impact of recent invention and innovation in just one area. Look on or near your desk and you will likely see a TV, laptop, a modem, a printer, a cellphone, an iPad, and a few other electronic tools. Now let’s think about their origin. Each one was invented in the US by US companies with US citizens dominating their boards of directors. Now look at the labels on all of these high-tech tools at your desk: they are all made overseas. So perhaps we should examine what has really happened—and more importantly, what is likely to happen—and most importantly, what we can do differently.

To understand the issue, it is necessary to introduce and focus on the “jobs multiplier”: the number of jobs created by one manufacturing job. The workers employed in manufacturing need raw materials, trucks to ship finished goods, schools, dry goods stores, food stores, restaurants, hospitals, doctors, nurses, recreational facilities, local water and power plants, and many other things. Those jobs are called consequential jobs because without the jobs in manufacturing, fewer of the consequential jobs would exist.

This concept is widely recognized, but there are wide ranges reported for multiplying factors—from 1.58 by the National Association of Manufacturers, to 16 in a case cited by Nosbasch and Bernaden (Jasinowski 2013.) There have been individual studies that have shown specific industries like coal mining have a multiplier of 4.0 (Cetnarski 2011). What is needed is a definitive study by type of manufacturing to enable accurate estimating.

For instance, it is clear that the manufacturing of goods has a higher multiplier than mining and that mining has a higher multiplier than service jobs. Manufacturing goods requires raw materials arriving at one dock and a higher-value finished product going out on another dock, which requires an infrastructure of utilities. Mining has outgoing bulk transportation, but the raw materials already exist and the utility infrastructure is small by comparison. Service jobs like teaching, nursing, doctoring, store keeping, etc. are vital and necessary, but require even fewer loading docks, shipping docks, and dedicated utility infrastructure. So service jobs have a low multiplier (many sources cite this multiplier to be less than one.)

With even this layman’s definition of multipliers, you can see how a move from a “manufacturing society” to a “service society” will result in the loss of huge numbers of jobs (Hilsenrath et al. 2016.) Any society has a limit to how many manufacturing jobs can be lost before that society’s well-being is significantly impacted.

UNDERSTANDING THE IMPACT

Painfully, the negative impact of manufacturing job loss is not uniform. Older workers may have retirement plans to partially offset the impact, and highly educated or highly skilled workers can find service jobs like selling or repairing all those electronics on our desks. The negative impact, however, is much larger for the younger and less skilled or less educated. So social equality is distorted, and resentment is created; resentment because citizens were not alerted to prepare them for this outcome.

There are numerous other factors resulting in manufacturing job losses, one example being fewer jobs due to automation. Automation replaces jobs because of the lack of a skilled workforce and the high cost of labor. This and other factors must be considered, but they do not change what we believe is the ultimate source of the losses: US policy toward US manufacturers.

Once upon a time, US invention and innovation did create jobs in the US; but once upon a time there was a different playing field. In the past, a larger percentage of manufacturing companies were US companies with US boards. Many were family owned. Federal policies favored US manufacturing. As examples, there were US tariffs to protect jobs, and fewer job-related regulations. The same was true in other countries so, except for wages, there was a reasonably level industrial playing field.

However, US policy has turned toward preserving the high US standard of living through policy that encourages the importation of goods; this keeps prices lower so the same or an even smaller paycheck can buy the same or more goods. This sounds like a good approach. Like many good approaches, however, the consequences are often in the details. In order to facilitate the importation of lower-cost goods, trade barriers were removed with little regard for the industrial playing field (Scott 2003) (Rihani 2002) (Roach 2016) (Senate Bill S.891 2015-2016).

At about the same time, national policy, again for mostly good reason, accelerated regulation of manufacturing. However, these same regulations were not being imposed in low-cost countries, and no compensation was made for this “unleveled industrial playing field.” Key US regulations included, but were not limited to, Equal Employment Opportunity, Occupational Safety and Health, American Disabilities Act and, more recently, the Affordable Care Act. All of these regulations had good provisions intended to protect American workers. They have contributed, however, to a negative impact on American workers’ jobs by creating financial advantages for low cost countries that do not impose similar regulations.

For US manufacturing, add to the burden stricter US environmental regulations, plus a costly and time-consuming permitting process that, in many cases, can take a year for approval even if all regulations are met. This is another good intention that has hampered construction of US manufacturing facilities and sent these facilities to low cost countries without similar regulations. What’s worse is that there are many cases where the shift in manufacturing to low cost countries has increased world industrial pollution.

The intricate permitting process means a heavy manufacturing facility in the US requires US$30-50 million of engineering and technical effort just to file permits. Smaller facilities require far less capital, but the permitting time for a fully compliant facility can be excessive.

THE ROLE OF INNOVATION

So how does research and innovation have a place in the increasingly global US economy? Research and development done as it was in the “good old days” will not contribute to the solution like it used to because of the reduced chance to reap the full value of the innovation. Assuming that a company wants to create US jobs through innovation—and may be willing to sacrifice a little to do so—a whole new outlook is needed. To reap the rewards of innovation, the key will be to find relevancy. Relevancy includes at least three factors:

• First, the item invented must provide significant economic benefits over currently preferred products.

• Second, the invention must be made with recognition of the necessary overall innovation needed (Cormier et al. 2016). The inventors and innovators must work closely to address the whole supply chain and create a suite of patents to protect their invention from copy.

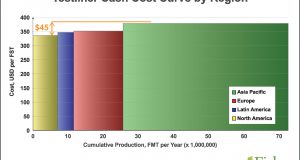

• Third, the innovation must create a transportation barrier to off-shore companies—for instance, by focusing on bulky products that have a high transportation cost, or on products that use raw materials with high transportation costs. One successful developer sees a reinvention of the chemical industry in which a differentiating factor will be selective replacement of petrochemical feedstocks with agricultural feedstocks (Stone 2016).

Studying the details of reverse engineering shows how daunting this task can be for an entire suite of patents (Elian 2005). Also, a suite of patents usually provides complementary benefits, increasing the economic impact of the initial offering. To protect any innovation, this suite of patents up and down the supply chain must be designed to confine heavy manufacturing jobs to the desired location. This sounds difficult and expensive—and it is. Furthermore, it does not guarantee that national policy will support it.

Creating a suite of patents is difficult and expensive because we are trying to use invention and innovation to overcome huge differences in the industrial cost playing field, much of which has been brought on by an accumulation of unbalanced national policies. The bottom line is that, as researchers or policy makers, we must avoid the shallow thinking that a single invention or innovation will automatically and permanently add jobs in the US.

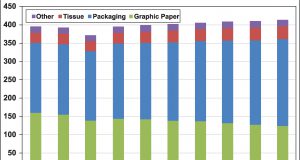

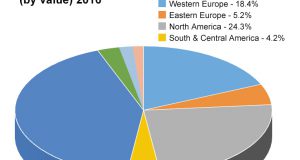

The third point about transportation cost has not been fully exploited. Manufacturers of tissue products try to manufacture them as close to major metropolitan areas or intermodal rail hubs as possible. There is an emerging class of bio products, made from the nation’s abundant biomass, that is regionally harvested and expensive to transport. Manufacturers should recognize that research and innovation for converting our nation’s biomass to high-value products will generate significant, good paying jobs in the US. With the right emphasis, this recognition could result in national policies to accelerate the growth of this pathway.

To be able to maintain and grow our manufacturing jobs and the consequential jobs that flow from them, we must do our best to influence public policy toward leveling the playing field in order to create manufacturing jobs in America. When the playing field is leveled and the lower risk is recognized, innovation will be encouraged and growth in manufacturing will return to levels that will provide the jobs required for economic stability. We need to encourage smarter US policies—like promoting research and innovation in bio products—because these jobs will stay in the US and create other jobs due to the multiplier effect.

CONCLUSIONS

Retention and creation of high paying manufacturing jobs is more important to the US economy in general, and rural economies in particular, than simply creating service jobs, due to the effect of the job multiplier. Yet national policies (including additional regulations and removal of trade barriers) have added burdens to the manufacturing of goods in the United States that other countries do not face. The result has been the loss of US manufacturing and the direct and consequential jobs that go with it.

Current invention and innovation efforts must incorporate expensive layers that will keep innovations from immediately being manufactured outside of the US. Industry leaders should be at the table in a bipartisan way with their elected officials (state and nation) to make sure that US policies help create a level playing field for US industry.

As a part of influencing public policy, we must educate our employees, citizens, and local, state, and federal officials about the fundamentals of manufacturing and national economic policy. If you think it is hard to innovate up and down the supply chain, consider how difficult this education will be. However, the results will be worth the effort.

Note: An article on this topic by the same authors was recently published at The Hill: http://thehill.com/blogs/congress-blog/economy-budget/313072-make-america-the-land-of-manufacturing-again

References:

• Cetnarski, Eric (2011). The Employment Multiplier – An Important tool for Promoting the Burgeoning Green Economy. Presidio Economics, Triple Pundit.

• Hemphill, Thomas and Perry, Mark. (2015). Putting US Manufacturing Growth into Perspective. Real Clear Markets.

• Jasinowski, Jerry (2013). The Magic Job Multiplier of Manufacturing. Huffington Post.

• Hilsenrath, Jon and Davis, Bob (2016). Tech Boom Creates Far Too Few Jobs. Wall Street Journal, p. A1.

• R&D in the Pulp and Paper Industry: To Innovate, Cooperate. Paper 360°, Sept/Oct 2016, P. 12.

• Elian, Eldad (2005). Reversing – Secrets of Reverse Engineering. Wiley Publishing, Inc. Indianapolis, IN.

• Rihani, Samir (2002). Complex System Theory and Development Practice, Understanding Non-Linear Realities, Zed Books, p. 137.

• Roach, Stephan S (2016). The Globalization Disconnect. Project Syndicate.

• Scott, Robert E (2003). The High Price of ‘Free Trade’- NAFTA’s failure has cost the US jobs across the nation. Economic Policy Institute.

• Brown, Sherrod; Senator [D-OH] (2015-2016). Senate Bill S.891, 114 Congress, Leveling the Playing Field Act.

• Stone, Joel (2016). Private conversation with Joel Stone, President, ConVergInce Advisors.

Masood Akhtar is president, Harry Seamans is treasurer, and Ben Thorp is vice president of the Biorenewable Deployment Consortium in Madison, WI. The BDC’s mission is to help deploy economic bioprocesses operations that will be economic without government subsidy long-term. BDC membership is made up of forestry companies, pulp and paper companies, and bioprocess companies. Learn more at bioenergydc.org.

Total U.S. manufacturing employment, 1970–2013. Shaded areas denote recessions. Source: Bureau of Labor Statistics (2014a).

Research and development done as it was in the ‘good old days’ will not contribute to the solution like it used to because of the reduced chance to reap the full value of the innovation.

Paper 360

Paper 360