Editors’ Note: This detailed case study was first presented as a webinar by the Biorenewable Deployment Consortium. Session speakers were Don Simola, who at that time was technology director at Andritz Oy, Finland; Leif Sjöblom, then senior project manager at Södra; and Johan Isaksson, PhD, who was a specialist in energy technology at Södra.

Demand for bio-based fuels and chemicals is expected to rise steadily in response to changing global standards for CO2 emissions. This could offer a tremendous opportunity for facilities able to invest in technology to create marketable side-stream products.

One such example is the industry’s first fossil-free biomethanol plant operating at Södra’s Mönsterås pulp mill in Sweden. The plant now produces 5,250 metric tpy of biomethanol as part of the company’s Liquid Forest™ line. The product has properties and quality equal to all types of commercial methanol, opening a host of new market opportunities for Södra.

MEET THE PLAYERS

The plant that creates the purified methanol is from Andritz, a leading global supplier of plants, equipment, systems, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and solid/liquid separation in the municipal and industrial sectors as well as for animal feed and biomass pelleting. Andritz offers equipment and technology production for all types of pulp, paper, tissue, board, and energy boilers.

Methanol purification is part of the company’s A-Recovery+ modular chemical recovery concept. According to Don Simola, Andritz, this model targets better mill profitability through cost-savings and additional revenue generation. The goal is to minimize the use of fossil-based raw materials and better utilize the side streams. The three available modules of the A-Recovery+ chemical recovery concept generate profits by valorization of raw methanol, concentrated non condensable gases (CNCG), and lignin side streams.

Södra is a forestry company based in southern Sweden. The company is owned by 53,000 forest owners throughout Sweden. With three pulp mills (Värö, Mörrum, and Mönsterås) the company’s pulping division, Södra Cell, is one of the leading producers of market pulp in the world. Södra Cell is also a major producer and supplier of biofuels, green electricity, district heating and raw material for liquid biofuels. With a strong focus on sustainability, Södra has long pursued energy efficiency measures; all three pulp mills have an excess of energy and are essentially fossil-free in production.

WHY PURIFIED METHANOL?

Methanol is a by-product from pulping, which means that no additional raw material is used in this process, apart from the chemicals used. Based on 2018 figures, global demand for methanol was more than 80 million metric tons and it has been growing steadily. Methanol has a number of traditional feedstocks:

- Natural gas represents more than 65 percent

- Coal represents roughly 35 percent

- Renewable sources (non-fossil sources) represent less than 1 percent of sources of methanol. This can be considered biomethanol.

Normally, biomethanol is produced from agricultural waste. Another source is municipal waste from various feedstocks. As a renewable methanol, another source is CO2 capture plus renewable hydrogen produced by water electrolysis.

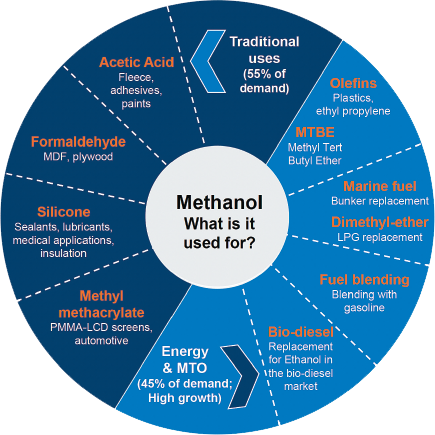

Simola pointed out that methanol is one of the most important commodities used as a starting material for different chemicals such as silicones, acetic acid, and formaldehyde. One big, growing sector is energy and MTO—methanol to olefins (see Fig. 1). As a green fuel, it is becoming more important, so there is increasing interest in biomethanol as component of bio-diesel or other fuels. One reason for this is different EU mandates for renewables and different directives for the uses of biomethanol.

When methanol is recovered during the wood pulping process, it’s often quite heavily contaminated. Due to this, methanol use externally has been a big challenge. For that reason, methanol produced during the pulping process is usually burned in the recovery boiler. To be marketable outside the mill, this methanol must be purified.

THE MÖNSTERÅS PLANT

When the Mönsterås biomethanol plant was first inaugurated, delivered capacity was five thousand tpy of purified methanol; today, the mill reports a capacity of 5,250 metric tpy. The purified methanol can be used as itself, as a fuel (biomethanol), or as a component in different biofuels—for example, in biodiesel.

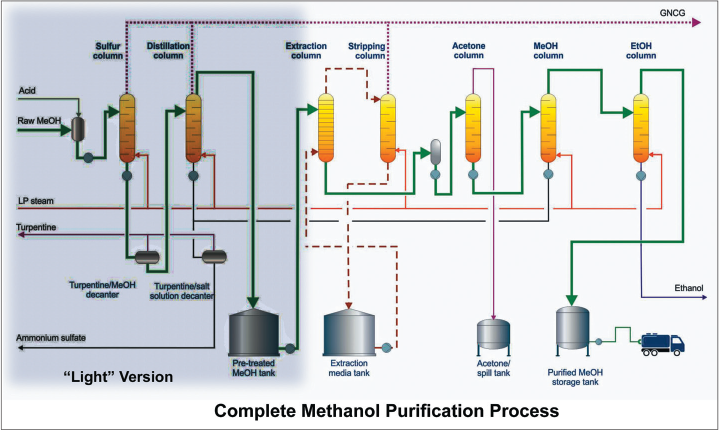

The equipment installation is modular, which allows for two configurations: light purification and full purification (see Fig. 2). The methanol produced from the “lighter” process is already acceptable as a biofuel for certain applications—for example, as a lime kiln fuel. One side stream is turpentine, which is returned to the mill; another is ammonium sulfate, which is considered a good nutrient for biological effluent treatment.

For full purification, the light purification is followed by a series of additional columns. In full purification, these extra steps remove the organic and inorganic sulfur compounds that are not removed by the first distillation. The process continues through several distillation phases to produce standard methanol, which can be used in different fuel blendings, for instance, in bio-diesel production. It can also be used by the pulp mill internally in the chlorine dioxide process. The system’s modularity allows the process to proceed from light purification to the final distillation stages, depending on quality requirements.

Because the execution is modular, Andritz is able to pre-fabricate the column modules to minimize the installation time and labor work, depending on the site. This means that equipment piping and instrumentation, and components such as safety devices, are pre-installed in the workshop, then shipped to the installation site, as per specification.

In addition to equipment safety, the mill made special efforts to address process safety. As Södra’s Johan Isaksson points out, flammable liquids and gasses had always been in use at the pulp mill, but the methanol purification plant represents a new context within a new and complex process. Before startup, the mill did a thorough risk analysis to identify areas with increased risk of exposure to flammable and toxic media. The mill developed an ATEX classification plan, which was then translated into personal safety standards. ATEX, which stands for “ATmospheres EXplosives,” is a European Union directive consisting of safety procedures regarding material, equipment, and systems used in environments with a risk of potentially explosive atmospheres.

SUSTAINABLE STANDARDS

Södra knew it would be important to be able to prove to its customers—and for them to prove to their customers along the value chain—that the company’s purified methanol is a sustainable product with a low carbon footprint. They chose to certify the product through the International Sustainability and Carbon Certification (ISCC), an independent, multi-stakeholder initiative and leading certification system supporting sustainable, fully traceable, deforestation-free, and climate-friendly supply chains.

The plant was the first of its kind in the industry so, as Södra’s Leif Sjöblom points out, at the onset of the project no one on the team knew what final parameters could be achieved. The plant started up in November 2019 and was running to higher capacity by the end of January 2020; Sjöblom reports that during that time, operators and Andritz were fine tuning the process. He says that the plant was soon up to 99.99 percent methanol purity.

Once the process had been refined, Andritz was able to guarantee results to the ISCC standards for many of the most important contaminant values, including sulfur, water, ethanol, and acetone. This guarantee of certified standards makes it much easier for the mill to market the purified methanol to potential customers.

Most important for the success of this project has been the dedicated team of operators at the mill sites, says Isaksson. The team was able to develop a close collaboration with Andritz. He notes that the mill was able to quickly realize that there was no startup curve regarding flow; the process gave the best results running at full capacity.

Regarding quality, the process was more complex, with many interacting steps. When fine-tuning, one change at the beginning takes quite a long time to promulgate through all the different distillation columns. It can take patience to operate the plant to the highest level. Deposits can also be a challenge, but operators have developed several ways of handling the issue.

With the attention to quality and adherence to ISCC standards, the purified biomethanol can be sold into any market where fossil-based methanol is used. Comparable costs will be dependent on local subsidies and tax regulations, notes Sjöblom; these generally favor the use of greener fuels and chemicals.

One of the first reported customers for the purified biomethanol was a Danish biodiesel producer. Several chemical companies also expressed early interest; another early customer was Pond’s, an American skincare brand owned by Unilever, which planned to use the biomethanol as a chemical component in its fragrance and flavor business. That is really interesting to us,” Sjöblom said, “because it shows that this product is not only for fuel.”

Paper 360

Paper 360