Based in Austria, BHM Ingenieure is one of the leading engineering and consulting companies in the European paper industry. The company specializes in design and project management services for buildings and outside facilities and has provided its services to the industry for more than 30 years, mainly in Europe, but also around the globe.

As experts in the field of building related overall engineering and project management, BHM is aware of the complexity of these types of projects due to the enormous amount of process equipment, automation, and intralogistics. The coordination of all engineering disciplines involved is crucial to an efficient design process.

“As a market leader in the field of construction planning for the paper industry, we always aim to offer our customers the best possible service. This means that, besides the permanent training of our highly qualified and experienced staff, BHM is using state-of-the-art and proven technology for the performance of its services,” says Peter Oksakowski, managing director of BHM Ingenieure.

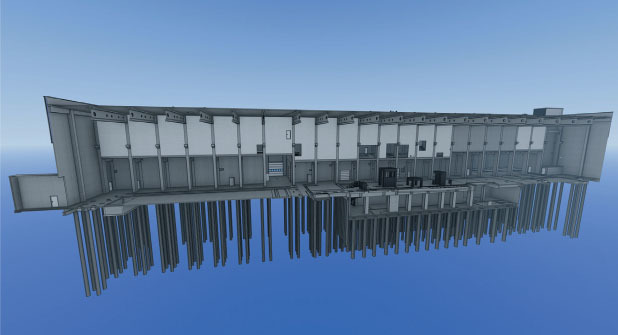

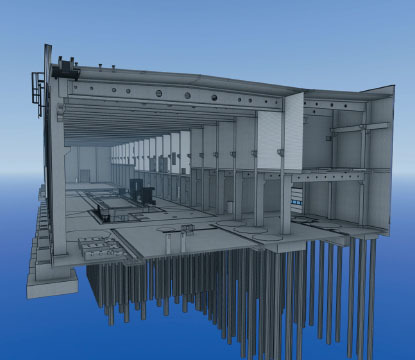

BHM started using Building Information Modeling (BIM) in 2015 for its engineering services, creating digital twins of the facilities to be built. This required not only the training of all designers regarding the new software, but also a totally different design approach.

One of the recent projects where BHM provided overall design, project, and construction management services was the new paper machine PM2 at Vajda Papir Kft. in Dunaföldvár, Hungary. PM2 is one of the most modern tissue machines in the industry, with a capacity of approximately 80,000 metric tpy and a design speed of 2,200 m/min. The Vajda PM2 project was successfully completed within only one year, from the commencement of construction to the successful start-up of the tissue machine. BHM Ingenieure provided overall design and project management for the PM2 project related buildings as well as basic design for outside facilities. BHM decided in the very beginning to implement a BIM design process.

CHALLENGES

- A very challenging deadline: Vajda-Papír was eager to start up the new paper machine in the shortest time possible to be able to cover the market demand concerning environmentally sustainable tissue products.

- To host the new PM2 in a suitable space, directly attached to the existing PM1 building, fitting with the other equipment in such a way that enables the company to optimize the thorough working flow.

- Material shortage as well as supply chain issues due to the COVID-19 pandemic crisis.

- Increased on-site coordination and safety measures because of simultaneous ongoing operation of existing PM1, installed only four years prior.

MILESTONES

- Start of basic design tissue machine building: December 2020

- Enabling works and deep foundations: April/May 2021

- Start of civil construction PM building: June 28, 2021

- Start of process equipment installation: December 2021

- Start-up of PM2: July 6, 2022

“One of the essential factors that enabled success of this project, besides the passionate and impressive commitment of the whole Vajda Papir project team, was the intensive communication with all parties involved from the very beginning. In addition, the 3D models created by BHM, using our BIM software, improved a lot the coordination between all design disciplines, especially between process and civil design,” says Rene Roos, project manager from BHM Ingenieure.

Designing with BIM helps architects, engineers, and contractors to visualize what has to be built in a virtual environment to identify any potential risk concerning design, construction, and interfaces to be coordinated between building design, process engineering, and operational issues.

When building projects are planned using BIM technologies, design and construction teams are able to work together more efficiently. As data is collected in the 3D model throughout the design and construction phase, it can be analyzed and used to develop ways to make processes more efficient.

In addition, the BIM model also provides multiple benefits for the whole life cycle of the facility. Depending on the LOD (Level of Detail), the BIM model can be used as a database for operational topics and maintenance issues; for example, product or material information, supplier, service sequence, etc.

BIM also improves safety by pinpointing potential hazards and issues before they become a real problem. Potential risks can be detected upfront in the model, which helps when it comes to creating safe conditions during construction, installation, operation, and maintenance.

BENEFITS THE BIM DESIGN APPROACH

- Better communication between the design disciplines by exchanging 3D models.

- Improved design quality by using one coordinated 3D model to generate drawings.

- Enhanced check of interferences between process design and civil design.

- More accurate and faster preparation of tender documents.

- Optimization of building structures.

- Significant optimization of construction sequence.

- One model as database which can cover the whole life cycle of the facility.

On the other hand, the BIM design requires a quite different approach when compared to a conventional design method. Designing with BIM needs very close coordination, right from the beginning, between all parties involved.

“Due to the detailed coordination of the 3D model at an early stage of the project, we could avoid any major changes later on. Furthermore, we were able to provide a complete set of pre-cast overview drawings to the contractor immediately after closing the agreement, which saved several weeks compared to the original construction time schedule,” says Tobias Gassner, BHM lead designer for the Vajda PM2 project.

In the PM2 project, the first relevant clarifications took place between Vajda Papir owner Attila Vajda, who constantly followed the project, BHM Ingenieure and the paper machine vendor. Many decisions were taken in the first few weeks after the design start. For example, decisions were made early on regarding the grid system, main floor levels, load specifications, specifications for routing, and installing of the Yankee dryer.

Besides the efforts and experience of all parties involved forming a highly motivated team in the Vajda Papir PM2 project, the BIM design approach implemented by BHM Ingenieure made it possible to achieve the target to have salable tissue just one year after commencement of construction.

Vajda says: “With the PM 2 project, BHM demonstrated again that the involvement of a professional, experienced, and highly qualified engineering company can shorten the project period significantly, which of course pays off for every investor. I´m very satisfied with the performance of BHM Ingenieure, a company we have been partnering with for several years.

“However, we all were able to succeed in this project not only because of the professionalism involved, but also because of the strengths of the various partners and their dedicated passion in the joint work undertaken.”

Paper 360

Paper 360