With the rising cost of energy, any reduction in energy use—especially in the energy-intensive refining area—is good news for a pulp and paper mill. However, only thorough research can it be determined whether a proposed change will yield positive results with no loss of quality or efficiency.

The Cartiere del Garda mill in Riva del Garda, Italy, part of Lecta Group, has two paper machines and produces 345 thousand tpy of coated graphic paper. A collaboration between the mill and RCK Chemicals, part of NCR Biochemical Group, enabled technological research into the use of enzymes in the paper manufacturing process aimed at energy saving while retaining the end product’s characteristics within required standards.

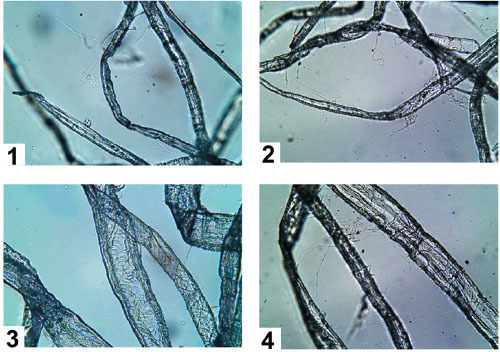

From left to right, the images show unrefined short fiber (1), unrefined short fiber with Renzyme 150 ppm (2), unrefined long fiber (3), and unrefined long fiber with Renzyme 150 ppm (4). This illustrates a positive trend linked to processing the selected Renzyme line product on both the short fiber pulp and on the long fiber pulp.

“At this particularly challenging time from an energy viewpoint, RCK Chemicals chose the Cartiere del Garda mill as a technical partner for its cutting-edge research. This collaboration made it possible to launch an extremely ambitious technology research project. The objective was to combine reducing energy consumption in refining with consequent reduction of CO2 emissions, while retaining or improving the quality of paper produced,” says Lorenzo Sorci, deputy technical manager, paper division, NCR Biochemical Group.

In addition to Sorci, the project team included Simone Cocco, deputy manager, production department for Cartiere del Garda; Mauro Ratto, R&D laboratory and CQ manager, Cartiere del Garda; and Giuseppe Schiavo, key account manager, NCR Biochemical Group. The team’s technical expertise would enable evaluation of the data collected.

ONGOING COLLABORATION

“Our long-term, proactive collaboration with Cartiere del Garda technicians has delivered ongoing quantitative and qualitative improvements in the production process,” says NCR’s Schiavo. “Market challenges provided the impetus to launch this research project, with the idea that we could verify the use of enzymatic formulations on fibrous materials to reduce the specific energy used in refining.”

Following preliminary laboratory research, the team tested the application in mill trials. The trials confirmed savings both in terms of energy consumption and chemical management in the wet forming section without sacrificing end product properties. “Initial industrial tests confirmed the performance that we hypothesized following the laboratory tests. The enzymatic treatment effectively reduced specific energy in refining by about 30 percent due to increase in fibrillation of long fibers,” he says.

“Cartiere del Garda has strict QC protocols for mechanical properties (Scott Bond, tensile, tear), thickness, stiffness, printing (mottling, ink-set, delamination, particle detachment), and converting (die-cutting and corrugating),” Schiavo continues. “Using the product selected from the Renzyme range on long fiber has also made it possible to retain end product properties unaltered, as verified by the laboratory and printers.”

CHOOSING THE PRODUCTS

Sorci details the products used. “RCK Chemicals’ Renzyme range comprises selected enzymatic cellulose-based products able to deliver increased technical performance by improved fibrillation of cellulose fibers,” he says. “This reduces the amount of energy necessary in the precise refining of the pulp. The products possess different chemical properties, and their application depends on the client’s technical requirements and pre-established targets.”

The quality and flexibility of Renzyme products make them perfect for wide-ranging technical research with predefined objectives. The technical team began with laboratory research that tested different pulps from the mill with various products from the Renzyme line. Researchers compared the samples to ascertain which came closest to achieving the team’s ambitious initial objectives.

“Because various enzymes from the Renzyme range have different affinity with cellulose fibers, we decided to test each sample in the lab at different dosages to ascertain both the behavior and scope of each,” Sorci says. “That way, we could identify which Renzyme product could meet each target predefined by the mill. We applied these to the manufacturing cycle with excellent results. The Renzyme line is constantly evolving; all products are subject to ongoing technical research by our Research and Development Department, with the goal of improving quality and technical performance.”

DOING THE RESEARCH

Cartiere del Garda’s Simone Cocco offers further details about the team’s research. “Enzymatic technology is rarely used in the graphic paper sector. Our collaboration with RCK Chemicals and NCR Biochemical Group made it possible to test this technology, which enabled us to obtain excellent results both from an energy and production viewpoint,” says Cocco. “One highlight is the product’s ease of use—it requires only a simple, dedicated, easy-to-install dosing pump.

“At first we saw an increase in shopper grades and porosity measured on both paper machines,” Cocco explains. “This was subsequently offset by a gradual reduction in energy consumption in refining. Laboratory tests and online monitoring on the PMs have confirmed both the manufacturing and qualitative stability of our process when using the enzyme, with a considerable reduction in refining energy consumption. From a processing point of view, when using the Renzyme, we could reduce the dosage of other chemicals with no abnormal fouling of our production runs, even during long periods of use. This is due to a relative increase in interfiber bonding.”

FINAL RESULTS

The various tests carried out in collaboration with Cartiere del Garda confirmed that the selected Renzyme product was very effective in reducing energy consumption and CO2 emissions in the paper mill. These results led to an ongoing partnership between Cartiere del Garda and RCK Chemicals/NCR Biochemical Group. The enzymatic treatment that the team developed is a new benchmark in the market to optimize energy efficiency in paper mills.

The collaboration team’s next goal is to carry out similar tests on short fiber pulp. Both pulps will be treated to evaluate global optimization of energy consumption across the entire manufacturing cycle.

“Enzymatic hydrolysis of the fiber upstream of the refining section through the addition of the enzymatic mix proposed by RCK Chemicals, under precise processing conditions (pH, temperature, free chlorine concentration) and appropriate contact times, reduces energy input in conventional mechanical refining,” says Ratto, laboratory manager for the mill. “Internal and external micro-fibrillation linked to the enzymatic hydrolysis process significantly increases bonding points by virtue of the greater surface area and fiber compression, which therefore improves the felting process.”

This testing partnership has proven that cellulose-based products in the Renzyme range can successfully modify the morphology of cellulose fiber, offering many advantages both in terms of the production process and end product. The trials also showed that these products can be used in the production of printing paper, tissue, and special types of paper. “The tests we did prove ample opportunity for optimizing energy savings, while not highlighting any real weak points in terms of processing or quality of the end product,” Ratto concludes.

Paper 360

Paper 360