techlink| INSIDE

TJ SUMMARIES

The papers summarized here are from the February 2017 issue of TAPPI Journal and the March 2017 issue, featuring special content on lignin valorization. TAPPI Journal is an online publication of relevant and timely peer-reviewed research delivered via email and free to all TAPPI members. To receive TAPPI Journal, join TAPPI at www.tappi.org.

FEBRUARY |

NONWOOD PULPING

Low-temperature precausticizing — a hopeful approach for green liquor desilication

Xinxing Xia, Fang Wang, Xiaojing Qin, Tingting Tang, and Tianwen Zhou

As precausticizing quicklime increased, the Cobb value decreased and sizing effect improved.

Researchers investigated silica removal in the wheat straw pulping process by low-temperature precausticizing and the properties of second causticizing calcium carbonate (CCC). About 89.3 percent of silica removal was achieved when 20 per-cent of causticizing quicklime was added for precausticizing at 20º C for 60 min. After that, silica removal became slow. As precausticizing quicklime was increased to 30 percent, the amorphous material and the crack disappeared, and the specific surface area decreased significantly. When CCC was used as filler, the Cobb value decreased significantly, and the sizing effect improved as precausticizing quicklime increased.

Understanding the properties of CCC with different quicklime contents for low-temperature precausticizing and its effect on paper quality can mitigate issues caused by “silica influence” and let papermakers reuse CCC produced from the chemical recovery process of wheat straw soda pulping.

RECYCLING

Fractional pulping of packaging board in high consistency drum pulping

Heikki Upola, Ari Ämmälä, and Mirja Illikainen

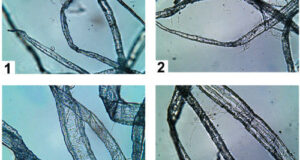

Illustration of disintegration efficiency in drum pulping.

A wide variety of packaging materials with different wetting rates and wet strength properties are used in old corrugated container (OCC) processing. The disintegration rates of the different grades vary and enable use of the fractional pulping concept where easily disintegrated material is removed at the early stages.

Researchers studied fractional drum pulping by pulping (pilot drum pulping) and fractionating (Tampella oscillating screen) a mixture of strong-grade kraftliner and weak-grade fluting at high consistency to see if energy consumption could be reduced. The results showed that a 25 percent energy saving could be realized through fractional pulping and an even higher potential might be possible if pulping conditions are optimized. Average fiber length, fines content, and ash content in the separated fractions were analyzed. The separated short fiber fractions and long fiber fractions could be individually processed, thus de-creasing the volumes in the unit processes on the OCC line.

LIGNIN PRODUCTS

Melt-blown compostable polyester films with lignin

Wolfgang G. Glasser, Robert Loos, Blair Cox, and Nhiem Cao

Prototype and (semi-)commercial products made from lignin-containing melt-blown and injection molded polymer blends.

Compostable films for such uses as packaging and agricultural soil covering materials were first produced on commercial scale from blends of biodegradable polyesters and a modified kraft lignin. The lignin consisted of an industrial product isolated by the LignoBoost process. The lignin modification involved homogeneous phase reaction with propylene oxide, and the films were melt-blown from a pelletized compound consisting of up to a 30 percent blend of lignin derivative with commercial bio-degradable polyester. The 12–93 μm thick films combined characteristics of lignin as modulus-building and environmentally degradable polymer with those of strength-building thermoplastic polyester.

Although the modified lignin paralleled the behavior of native lignin in wood by resisting rapid and full conversion to carbon dioxide in a simulated composting environment, two thirds of the film mass biodegraded within 12 weeks of composting, with the remainder turning into (humus-like) water-soluble solids and particles <2 mm in size. The lignin derivatives suffered from the release of trace amounts of malodorous volatiles containing reduced sulfur when subjected to melt-blowing. The objectionable odor was virtually unnoticeable in injec-tion-molded solid parts.

Use of kraft lignin as a contributing thermoplastic polymer component of melt-blown film and injection-molded products from sustainable resources with environmental compatibility helps the kraft pulping process advance toward a multi-purpose biore-fining technology with increased income potential.

LIGNIN CONVERSION

Accelerated aging of bio-oil from lignin conversion in subcritical water

Huyen Nguyen Lyckeskog, Cecilia Mattsson, Lars Olausson, Sven-Ingvar Andersson, Lennart Vamling, and Hans Theliander

Solvent fractionation of the lignin-derived bio-oil (DEE = diethyl ether; THF = tetrahydrofuran).

Accelerated aging of bio-oil derived from lignin was investigated at different aging temperatures (50°C and 80°C) and times (1 hour, 1 day, 1 week, and 1 month). The bio-oil used was produced by the hydrothermal liquefaction of kraft lignin, using phenol as the capping agent, and base (potassium carbonate and potassium hydroxide) and zirconium dioxide as the catalytic system in subcritical water. Researchers measured elemental composition, molecular weight, and chemical composition of the bio-oil to better understand the changes occurring after subjection to an accelerated aging process.

The lignin-derived hydrothermal liquefaction bio-oil was quite stable compared with biomass-pyrolysis bio-oil. The yield of the low molecular weight fraction (light oil) decreased from 64.1 percent to 58.1 percent and that of tetrahydrofuran (THF) insoluble fraction increased from 16.5 percent to 22.2 percent after aging at 80°C for one month. Phenol and phenolic dimers had high reactivity compared with other aromatic substituents; these may participate in the polymerization/condensation reactions in the hydrothermal liquefaction bio-oil during accelerated aging.

Moreover, the high molecular weight fraction (heavy oil) in the aged raw oil in the aromatic region showed the structure of this fraction was a combination of phenol-alkyl patterns, and the guaiacol cross-peaks after aging indicated a new polymer was formed during the aging process.

Pulp mill personnel can use this information when considering technology to extract lignin from black liquor and process it further into bio-oil.

ECONOMIC ANALYSIS

Analysis of economically viable lignin-based biorefinery strategies implemented within a kraft pulp mill

Cédric Diffo Téguia, Rod Albers, and Paul R. Stuart

Many pulp and paper companies are considering implementing a lignin-based biorefinery to diversify their core business to new products and improve their longer-term competitiveness. In this study, various lignin biorefinery strategies were considered in a case study involving lignin precipitation processes integrated within an existing kraft mill and solvent pulping processes that would be implemented in parallel to the existing mill processes using additional hardwood. The analysis aimed to identify the conditions under which various strategies would represent suitable investments.

Operating constraints in the case study mill limited lignin extraction to 85 metric tpd from 15 percent of the mill’s black liquor, whereas 260 metric tpd lignin could be extracted by solvent pulping 1500 metric tpd of hardwood. The preferred strategies identified by the study were lignin precipitation to phenolic resins production, and solvent pulping to carbon fiber production. The first product-process strategy requires lower investment, provides high returns (internal rate of return [IRR] of 39 percent to 43 percent), and is more easily implemented in the near term.

Solvent pulping resulted in reasonable profitability (IRR of 18 percent to 25 percent), with higher production volumes and a diversified product portfolio, and was considered more suitable as a longer-term strategy. Business model robustness and long-term competitiveness can be better assured by combining both strategies. It was shown that 1) government support to offset capital cost, and 2) high derivatives market prices positively influence lignin valorization strategies, which are sensitive to technology and market maturity.

This study illustrates how a technical and economic analysis could be used to identify lignin-based biorefinery strategies that represent an attractive investment.

Other research appearing in TAPPI Journal’s February 2017 issue:

PAPERMAKING

Estimating limits of wet pressing on paper machines

J. David McDonald and Richard J. Kerekes

PROCESS CONTROL

Understanding conductivity and soda loss

Michael T. Brown and Peter W. Hart

Other research appearing in TAPPI Journal’s March 2017 issue:

LIGNIN CHARACTERIZATION

An easy and reliable method for syringyl: guaiacyl ratio measurement

Raquel Prado, Lisa Weigand, Shikh M.S.N.S. Zahari, Xabier Erdocia, Jason P. Hallet, Jalel Labidi, and Tom Welton

Paper 360

Paper 360