Efficiency and waste reduction are crucial aspects of the tissue and paper-converting industry. While waste is an inevitable part of the converting process, there are various strategies and technologies that can be employed to minimize waste and optimize operations. In this article, we will explore the importance of waste optimization, the obstacles faced in the industry, and the opportunities for improvement through automation. By implementing effective waste automation techniques, paper converters can enhance productivity, reduce costs, and improve overall sustainability.

MINIMIZING WASTE: A NECESSARY EVIL

When converting paper products, the focus is primarily on maximizing production throughput and minimizing waste. However, it is essential to recognize that waste is an inherent part of the process. No matter how well waste is minimized, the more production that takes place, the more waste is generated. Often, the waste stream needs to be noticed amidst the optimization efforts in the facility. To address this issue, it is crucial to find ways to optimize without compromising production efficiency.

OBSTACLES AND OPPORTUNITIES FOR EFFICIENCY IMPROVEMENT

Manual labor poses significant challenges to efficiency, especially in the current labor market conditions. Finding and retaining skilled employees is increasingly more difficult, leading to staffing shortages and potential inefficiencies. On the other hand, automated machinery offers greater reliability and consistent performance. By automating various processes, manufacturers can reduce dependence on manual labor, free up floor space, and minimize safety risks associated with human error.

TYPES OF WASTE AND AUTOMATION TECHNIQUES

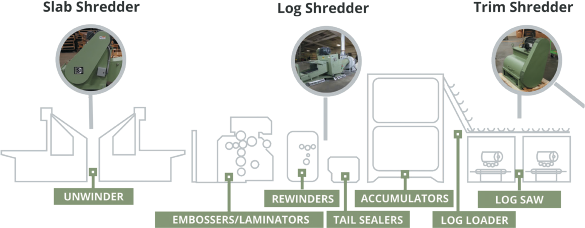

To effectively optimize the waste stream, it is essential to identify the different types of waste produced in the paper product converting process. These include slab waste (both prior to unwinding and spent rolls), log waste, roll, and trim waste. Streamlining the process by automating material transport can significantly contribute to waste reduction. Implementing shredders is a common approach to transforming waste materials into a more manageable and consistent form for further processing. Shredders can be strategically placed offline near unwinders to ensure minimal impact on uptime. Additionally, shredders can be installed online to handle log waste, roll waste, and trim waste (as it is discharged from the converting equipment), allowing for immediate disposal and transportation.

THE HIGHWAY IN THE SKY: CONTAINING WASTE AND DUST

One crucial aspect of waste automation is the implementation of a comprehensive air system; we like to call it the “Highway in the Sky.” The system includes ducting, fans, blowers, and filters to contain waste and dust particles generated during the converting process. This process facilitates the transportation of waste materials back to the pulper or other designated areas for recycling or disposal. By effectively containing waste, dust is collected, allowing converters to prevent its accumulation throughout the facility, reducing the risk of fires and improving overall air quality.

REAL-LIFE EXAMPLE AND ECONOMIC CONSIDERATIONS

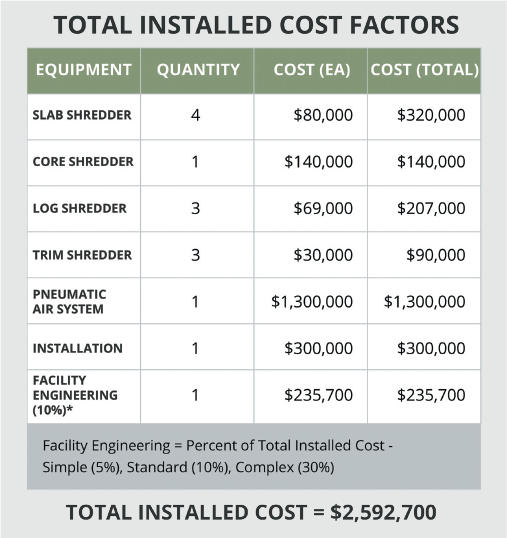

Let’s examine a hypothetical scenario to understand the economic impact of waste automation. Suppose a greenfield paper converting facility installs waste automation during an expansion project to install three new converting lines consisting of shredders, an air system, and other associated equipment.

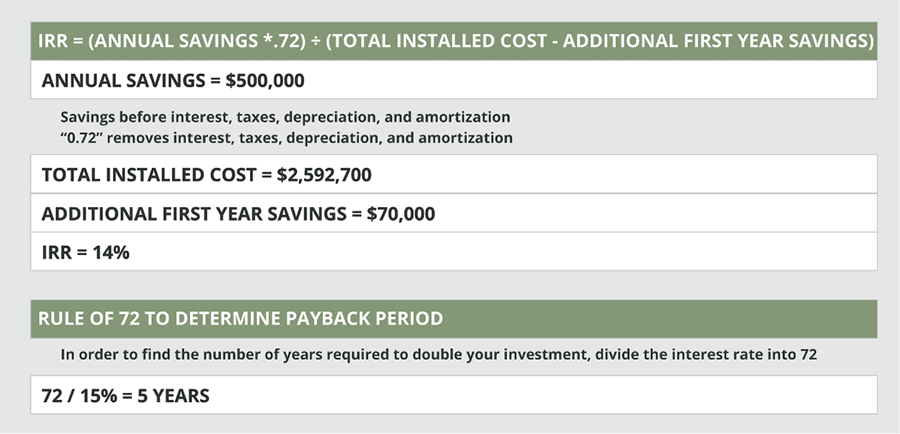

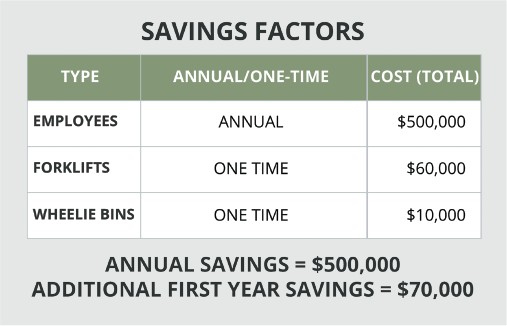

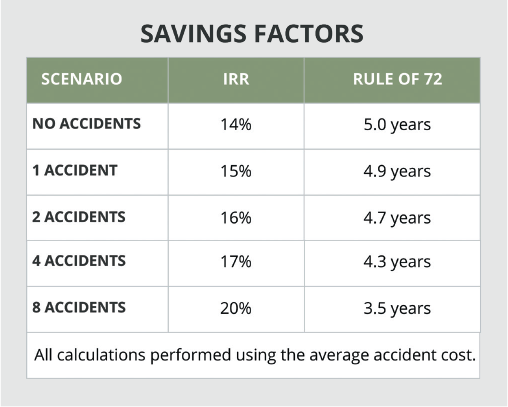

The total installed cost of such a system may initially seem substantial, but the long-term cost savings justify the investment. By reducing the number of employees required for waste handling, the facility can save significant labor costs annually. Additionally, the reduction in forklifts and bins further contributes to cost savings. Considering the internal rate of return (IRR) and payback period, it becomes evident that the investment in waste automation technology pays off within a relatively short time frame.

SAFETY AND ENVIRONMENTAL BENEFITS

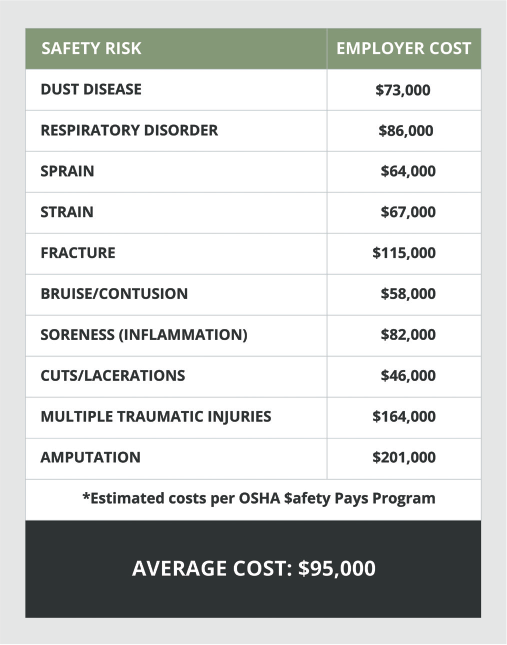

Automating waste handling and containing dust not only improves efficiency, but also enhances safety within the facility. By minimizing movement on the floor and reducing the risks associated with manual labor and forklift operations, converters can prevent workplace injuries and accidents. Moreover, effective waste automation practices reduce the fuel source for potential fires, and installing fire suppression equipment in the ducting system further enhances safety measures. When organizations invest in safety and reduce accidents, they also reduce liability, human suffering, and, ultimately, money. Accidents cost an average of $95,000 per accident. By that calculation alone, the reduction in time to pay back for implementing automation and optimization efforts shortens significantly.

THE KIND OF POSITIVE IMPACT YOU MIGHT BE LOOKING FOR

Automating waste management in the paper industry significantly benefits facility operations and safety, and is a true cost reduction project. By using automated systems like shredders and efficient waste transport, paper converters can minimize manual labor, streamline processes, and optimize production efficiency. The advantages include improved plant safety, increased worker productivity, and reduced operational costs. Automation allows operators to focus on core tasks, leading to higher production output and a safer work environment. It eliminates manual labor expenses, reduces reliance on equipment, and lowers maintenance costs, resulting in substantial financial savings.

Additionally, automated waste management systems address safety concerns by reducing injuries, mitigating fire risks, and controlling dust accumulation. Dust containment within shredders and air systems minimizes fire fuel sources and enhances facility safety. These systems can be tailored to fit existing or new production lines, adapting to specific processes and materials for maximum efficiency. Embracing automation in waste management enables the paper industry to improve productivity, profitability, and sustainability, ensuring the efficient use of resources and contributing to industry advancement.

Paper 360

Paper 360