These are the final two installments in a series by corrugated equipment specialist Jim Brown. These articles have outlined what the board experiences during the conversion process, but from an unusual perspective: that of the board itself, in the form of our imaginary narrator, Corra Gator-Boardy. We hope you have enjoyed riding along with Corra in this series of six mini-adventures on her transformation from a flat corrugated board to an amazing, corrugated container.

We have followed Corra through the machine press sections of a flexo-folder/gluer; she was now ready for her final journey as she travels through the folding and gluing section and counter/ejector.

FOLDING / GLUING

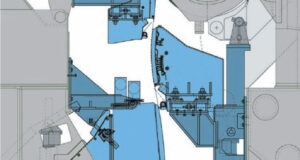

Corra flew out of the slotter nip and into the folding section onto a pair of urethane-topped belts. The belts grabbed her from underneath and transported her forward, toward the counter/ejector section. But before any folding could begin, she needed to receive stripes of wet glue on her operator side glue tab. A glue applicator squirted several beads of glue on the top surface of her glue tab as she passed underneath the nozzles.

Now she was ready to get folded! Ahead of her were adjustable, round folding rods that curved in such a way as to lift her outer panels as she proceeded along the vacuum folding rails that held the rest of her down flat. The panel with the glue on it folded slightly ahead of the opposite panel, so that when folding was completed, the glue contact joint was made. The quick-drying glue began to set as she speeded forward, toward the counter/ejector section.

COUNTER / EJECTOR

Corra entered the counter/ejector through a compression nip—a pair of rollers that perfectly squeezed her glued flaps together to help finish the glue tab bond. Still moving at a rapid pace, she was immediately knocked downward by a series of plastic loops that whipped around on a shaft above her. Then she came to an abrupt stop as she slammed into the backstop, the back wall of the counter/ejector hopper.

She noticed that she had been reunited with the rest of her family who she had not seen since being stacked into the feeder hopper. But now she had been fed, printed upon, die cut, slotted, glued, and folded! As she neared the end of her great transformation, she was lowered incrementally with the others in an elevator section as they were counted and positioned to travel through the compression section. A pneumatic pusher extended and quickly moved her and her family off the elevator and into an upper and lower array of powered belts that were adjusted to squeeze them all together, further setting their glue flap bonds.

Well, there was nothing left but to be ejected and strapped together with her family as she exited through the automatic band strapping machine and rolled onto the ball bearing conveyor rollers.

What a transformative process! Corra had been converted from a flat piece of corrugated board to a real corrugated container. Looking behind her, she remembered the amazing ride through the converting machine, each section progressively changing her into a useful box. Now she was being loaded onto a truck, headed out to market to transport everything from berries to batteries, and she was ready.

SHARE CORRA’S STORY!

We hope readers have enjoyed this unique series of articles. Whether you’re a seasoned corrugated professional, a vendor eager to learn more about customer processes, or a new hire to the industry, there is always more to learn about the sequence of steps that turns a flat corrugated board into a custom-designed corrugated container.

If you’d like to request a free PDF compendium of every article in this series, drop a note to Editorial Director Jan Bottiglieri ([email protected]). Readers will be free to share this pdf with customers, clients, vendors, students, or others in the industry who may benefit from an expert and entertaining overview of this amazing process.

Paper 360

Paper 360