It’s been almost 150 years since G. Smyth built the first machine for producing large quantities of corrugated board. Today’s corrugated machines are far more advanced, with new technologies introduced constantly to keep up with the sector’s explosive growth.

The promulgation of that technical knowledge is critical to further growth.

TAPPI’s Corrugated Packaging Division serves as a forum for knowledge-sharing in the corrugated packaging industry. Focused on the manufacture and use of corrugated containers and associated packaging materials and products, the division is comprised of members who work for manufacturers, converters, suppliers, consulting companies, and others in the industry. The division’s technical committees work together throughout the year to solve problems, develop technical papers, plan conference sessions, and more.

Many corrugated industry professionals are not aware of the opportunities available to join, contribute to, and learn from these active committees. A recent joint meeting of the Corrugated Board Technical Service Committee (Corbotec) and the Fiberboard Shipping Container Testing Committee (Fiscotec) highlight these opportunities. But what do these committees do?

Corbotec provides technical assistance to mills, container plants, and box customers in resolving board and container problems by promoting information exchange and communication between all elements of the process and distribution cycle. This committee meets twice each year to exchange ideas related to technical issues in all areas of the corrugated packaging industry.

Fiscotec is the committee in charge of maintaining TAPPI testing methods that apply specifically to containerboard, corrugated board, and corrugated boxes. These test methods are fundamental to the industry; they define what is meant by “Ring Crush,” “ECT,” “BCT,” and many other terms used to define corrugated products. To assure that each method remains current and accurate, they are reviewed on a regular schedule by their individual subject specific interest groups (SSIGs); the Fiscotec committee oversees this process.

QUESTIONS, ANSWERS, AND TIPS

The spring meetings for Fiscotec and Corbotec were co-located in Milwaukee, WI. During the Corbotec meeting, members broke out into small groups to work on TAPPI Technical Information Papers (TIPs) up for review and addressed necessary updates or changes. Corbotec also holds summer meetings; these are two-day events including technical presentations, plant tours, and review of “Ask Corbotec” cards—inquiries submitted anonymously by industry professionals, prior to the meeting, related to problems or issues they may be having. These inquiries are discussed collectively by the group and solutions are presented. This is a wonderful opportunity to learn and interact with peers and colleagues in a technical environment.

At Fiscotec committee meetings, new methods get proposed and members engage in technical discussions about new and existing methods in order to help make the methods (and the industry) better. Recent discussions have explored wet pin testing, DST (torsional stiffness), parallelism requirements for box compression testing, differences in ECT test methods (TAPPI has several), and flat crush, among other topics.

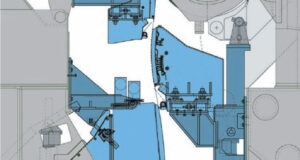

At this year’s spring meeting, Corbotec members also had the opportunity to visit Independence Corrugated in Oak Creek, WI, to tour the plant’s Quantum Corrugator. (Quantum is a member of Fosber Group.) Designed for flexibility, the Quantum line of machines offers compact dimensions, with a total length between 55 and 96 m, depending on the configuration.

GET INVOLVED

Any TAPPI member can join Fiscotec or Corbotec, and the committees encourage and appreciate active participation. To learn more about getting involved, contact the following committee chairs: for Corbotec—Mark Malinowski, Malintech Inc., [email protected]; or for Fiscotec—Jay Nason, Emerson Apparatus, [email protected].

Paper 360

Paper 360