Emerging technologies are a big part of CorrWeek. This year, the Technical Program Committee curated 15 “Tech Talk” presentations, offered over two days, that ran the gamut of the corrugated process. Eric Sextonson of Ringwood Starch Mix moderated both sessions.

Tech Talks give attendees the opportunity to learn about new technologies, products, or services that can help them be more productive and efficient. Each presentation is only seven minutes long, creating a rich environment for learning in a fast-paced setting. Here are this year’s highlights:

American Baler—Limited space demands a narrow-body baler, but that can’t mean sacrificing efficiency. The Model 5042WN-10T50 offers increased throughput and a capacity boost of 40 percent. Another benefit: reduced material handling, taking some pressure off busy crews.

AG Stacker—Improve end-of-the-line efficiency with the eBreak Bundle Breaker. The moveable platen design helps reduce waste, energy, and manpower. The company has even designed a digital twin of the Bundle Breaker for operator training and testing custom designs.

BW Papersystems—The company’s Servo Rotary Die Cutter can work for lightweight or heavyweight board, and combines an ultraheavy duty die cut system with an easy-to-use HMI system. Easy-to-see LED indicator lights support safe operation.

Baumer hhs Corp.—Want “greener” gluing? The CorrBox solution’s “stitch mode” can slash glue consumption, says Baumer. Other CorrBox components include a newly-designed interface that’s customizable for user experience, plus an easy-maintenance modular design and advanced glue monitoring.

Borregard USA Inc.—Reduced consumption of starch and energy are top features of the Exilva starch additive. Exilva is microfibrillated cellulose (MFC), a biodegradable, natural polymer that offers a host of functional properties to reduce bottlenecks while boosting your sustainability profile.

EAM-Mosca Corp.’s high speed strapping system comes with a transfer cart and an interchangeable third system.

EAM-Mosca Corp.’s high speed strapping system comes with a transfer cart and an interchangeable third system.

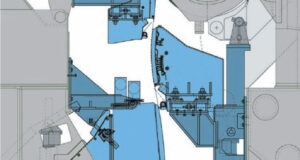

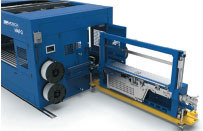

EAM-Mosca Corp.’s high speed strapping system comes with a transfer cart and an interchangeable third system.EAM-Mosca Corp.—The Max-Q-SoniXs High Speed Strapping System is all about flexibility. It boasts a 48 percent smaller footprint and a 50 percent greater throughput than the SQ4 Tandem; plus, it comes with a transfer cart and an interchangeable third system for easy maintenance.

Fosber America—Specifically designed for high graphic, micro-flute corrugated, Fosber’s Quantum Corrugator will help plants stabilize temperature on the substrate for optimal printing and stronger board, while dropping energy consumption by more than 30 percent.

HP Inc.—Drive digital transformation with HP’s PageWide T700i Press. It’s fast (print speeds up to 1000 ft/min), economical, and integrates seamlessly with HP’s One Package line. Consistent 6-color offset quality can be achieved on a range of papers with several pretreatment options.

Haire Group—With a “no crush servo feeder” that requires no operator intervention, the HGL series Rotary Die Cutters reach speeds of 12,000 sheets/hr with dual feed capability. The Encore HGL comes in two sizes: 1628 and 1632.

Kadant-Johnson—Detect defects before they happen with Thermo Zone Intelligent Condensate Handling. It’s built for tough environments and eliminates steam traps so there is no wasted steam or damage. Near-zero pressure makes it great for lightweight grades.

Kento Digital Printing—Offering both digital and analog printing capabilities, Kento’s Hybrid Single Pass Digital & Flexo Printer is designed for corrugated. Hybrid printing can tackle intense color backgrounds plus large printed areas, for ink costs up to 80 percent lower than inkjet alone.

Kolbus America—It’s “boxmaking on demand” with the AutoBox AB310, a range of short-run boxmaking machines that offer strong digital control plus an upgradable, customizable modular design. Ultra-fast automatic make-ready, an easy-to-use touch screen, and remote diagnostics keeps things on track.

SUN Automation Group—The Helios IIoT Platform operates throughout the plant to connect, summarize, and analyze massive amounts of data. The “secret sauce,” according to Sun? Machine learning that can help plants build a predictive model to identify the likelihood of downtime before it occurs.

Valmet—Ensure the quality of corrugated board with the IQ Quality Control System for corrugators. Online moisture, temperature, and warp sensors provide real-time information from the process while fast actuators reduce process limitations such as over-drying and uneven cross directional profiles.

WSA-USA, LLC—Validate plant layout, identify existing or potential bottlenecks, and much more with WSA USA/Warak’s 3D Plant Simulator Module. This digital twin technology uses real plant data to let customers view their plant running in real time, modeling real life operational situations.

Taken together, a few interesting themes emerged from the Tech Talks. Reducing bottlenecks is clearly top-of-mind for customers, as are operator safety and ease-of-use. Corrugated suppliers are also doing what they can to support customers’ sustainability goals and both sides seem ready to embrace corrugated’s digital future.

Paper 360

Paper 360