millwise| CONVERSION

Reinventing Varkaus

In 2015, Stora Enso invested EUR 110 million to reinvent its Varkaus fine paper mill in a bid to gain market share. The result is a first-class packaging facility.

When you visit Stora Enso Varkaus, Finland—the location of BM 3, a new 390,000 tpy virgin-fiber-based brown and white top containerboard machine—you know you are in a history-making place. Recently, the mill was reborn for the fourth time since 1921, this time to meet market needs for kraft liner and white top.

What’s evident immediately in Varkaus and the new containerboard facility is that old and new live side-by-side. Few towns and factories can claim design from architect Alvar Aalto, or such prominence and scale of industrial success over nearly a century. Yes, they have had serious setbacks in recent years, even the near closing of the mill. However, resurgence is happening again.

In 2015, Stora Enso invested EUR 110 million (US$116.5 million) to convert its Varkaus fine paper mill to a 390,000 metric ton/yr virgin-fiber-based brown and white top containerboard facility.

Modifying existing assets to become a new product line is part of Stora Enso’s transformation to being a value-creating renewable materials company. Through this machine conversion, it is positioned to gain market share in a growing world market, recognizing the decline of fine paper. Stora Enso is vigilant about quality, including key properties such as strength and printability.

The new facility includes an existing 310,000 metric tpy unbleached kraft pulp mill, a power plant, considerable infrastructure, and a competent workforce. The mill is also ideally situated near an abundance of local virgin fiber resources. It is energy independent, employing 95 percent bio-fuels with low CO2 emissions.

The conversion increases Stora Enso’s renewable packaging sales by EUR 280 million (US$ 296.7 million). The company reports that the targeted EBITDA margin for the converted machine at full capacity is above 15 percent, provided that current market conditions continue.

GLOBAL MARKET ADVANTAGE

With the conversion, Stora Enso considerably strengthens its global offering to customers in containerboard. The Varkaus mill’s domestic customers are in Europe; its global markets include South America and Asia. The value proposition is con-sistency with strength, moisture resistance, purity, and printability. For fruits and vegetables, food packaging, retail, and industrial heavy duty, the mill’s offering of kraft liner and white top is ideal.

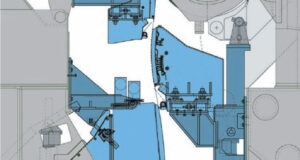

The mill also had an expert support team. Pöyry Engineering played a key role in the conversion. Valmet delivered a new headbox and wire section for reverse ply and modified the old wire section for print ply, as well as provided a shoe press. They revamped the paper machine’s dry end, including a quality control system.

Honeywell modernized control, security, and management systems—all from two fully integrated control rooms. A com-pact wet end and screening from Aikawa Fiber Technologies (AFT) for the new reverse ply eliminates many redundant pieces of equipment, and is an advanced version of Stora Enso’s pioneering work with this concept back in 2001.

NEARLY 100 YEARS OF SUCCESS AND EVOLUTION

Back in 1921 Varkaus, then owned by Ahlstrom, was the largest paper mill in Europe. In the 1980s, when Enso Gutzeit (Stora Enso since 1998) took over, the mill was a major newsprint producer. Its output supplied the newspaper plant of Helsingin Sanomat, the leading Finnish journal, as well as many other Nordic newspapers. Later in the 1980s, Varkaus made publication grades for magazines and brochures throughout Europe. It also started uncoated and coated fine paper production through conversion of two lines.

The mill is energy self-sufficient and now boasts usage of 95 percent bio-and recycled fuels, maximizing energy efficiency and minimizing fossil CO2 emissions. It also produces 310,000 tpy of unbleached kraft pulp from local, sustainably sourced and certified spruce and pine.

Says Mill Director Jarkko Tehomaa, “ Varkaus was a wise place for a conversion to containerboard, because an invest-ment of EUR 110 million, 10 times less than a greenfield mill, delivered a first class packaging facility. Our new board ma-chine was designed to balance perfectly with the existing integrated pulp mill and power plant. Well located from a raw material supply point of view, the necessary infrastructure and competence was in place. We also gained a lot from the Stora Enso Ostroleka (Poland) start-up team, who recently completed a major start-up of new test liner line.”

On a practical and tactical note, Tehomaa says, “ The paper machine’s existing trim width was just right for the new

end-products.” Tehomaa suggests that Varkaus benefits from the Stora Enso global sales network, which is now being enhanced in Europe and globally.

“ Our team is close to end users who demand strong containerboard that prints well. We are part of image-making for fruit and vegetable brands, as well as a range of industrial products. That’s why our range of brown and white top grades, light and heavy, are the right fit for diverse local converting.”

CORE SUPPLIERS

In addition to Stora Enso’s own experts, Pöyry engineering was instrumental in the conversion, including machine and process optimization from Valmet and Honeywell. In total, about 70 suppliers were involved for various specialization tasks.

Valmet handled construction and installation of the paper machine’s new headbox and shoe press and revamped the paper machine’s dry end. In addition, they supplied the mill with a new quality control system.

Honeywell was in charge of modernizing control, security, and management systems. Everything in the paper mill runs from two integrated control rooms. Only one control room runs the pulp mill and power plant.

LESS IS BETTER FOR WET END SYSTEMS

The compact system for approach flow and screening from AFT first proved itself at several other Stora Enso mills. According to Jukka Lyyra, area manager, paper machine, mill conversion project at Stora Enso, “ We knew we could count on AFT for their POM system, screens, and cleaners. There was no need for the traditional storage tanks and deculator, because AFT’s POM runs smoothly with much lower water and energy usage. There’s been no contaminant build-up. Less time for grade changes. Less air to disrupt the paper machine headbox process. Fewer defects and subsequent complaints from customers. We don’t think about it—AFT’s POM is almost dull, it’s so reliable! That’s the best kind of system in a board mill, because there’s always an issue somewhere.”

In fact, Varkaus was the first Stora Enso mill to install an early model of the POM system back in 2001. “ Some of the old-timers saw the value of a minimalist approach. Now, POM has been perfected, including easy monitoring in our controlroom.”

The AFT delivery includes a wet end system of two POMp degassers, a POMLock seal water drop leg and cleaning for the top ply, and a 3-stage back ply screening room combining three MaxFlow units in the primary and coarse positions and a tertiary MaxSaver screen to maximize fiber recovery.

“ Because the wire section is a bit short, the team had concerns about drainage capacity and higher speed. That’s why the two POMp730 degassers made sense for deaeration,” says Risto Nykanen, AFT project manager.

Adds Lyyra, “ Just the right amount of degassing without the civil engineering, capital, and running costs of a deculator was a wise move. We have full functional capacity and the flexibility we need in a very compact space.”

Stora Enso Varkaus at a Glance

• Saw mill, white wood timber: 260,000 m3

• Pulp mill, unbleached kraft pulp: 310,000 metric tpy

• Paper mill, containerboard: 390,000 metric tpy

• LVL mill, LVL: 100,000 m3/yr (start-up in June 2016)

• Wood usage: spruce, pine, birch—approx. 2.1 million m3 (after investments)

Paper 360

Paper 360