Many companies are committed to reducing their CO2 emissions before 2030. Saving 1.5 MW in the vacuum system equals a 4,000-ton CO2 savings per year on average. Runtech looks at energy-saving projects from a wide perspective. It is not only about the vacuum pump or the turbo blower in the basement. The target is to understand what happens at the machine levels and what might be wrong or causing problems on the paper machine. Understanding the dewatering process is key to a well-functioning vacuum system.

Runtech RunEco vacuum system is developed especially to take into account the challenges and demands related to the dewatering and runnability of paper machines. The traditional method of increasing vacuum levels is replaced with speed adjustable turbo blowers, optimal doctoring and save-all systems with online dewatering measurements. By using only the needed vacuum in the critical consumers, mills can fully benefit from the more efficient nip dewatering strategy and save energy.

EP Turbo Blower is a key element in the RunEco solution.

EP Turbo Blower is a key element in the RunEco solution.

The solution is a fully adjustable, energy-efficient vacuum system for tissue production. It is a tailor-made solution equipped with optimal save-all and doctoring system and online dewatering measurements. RunEco can provide energy savings of 30 to 70 percent and is applicable for both greenfield and rebuild projects.

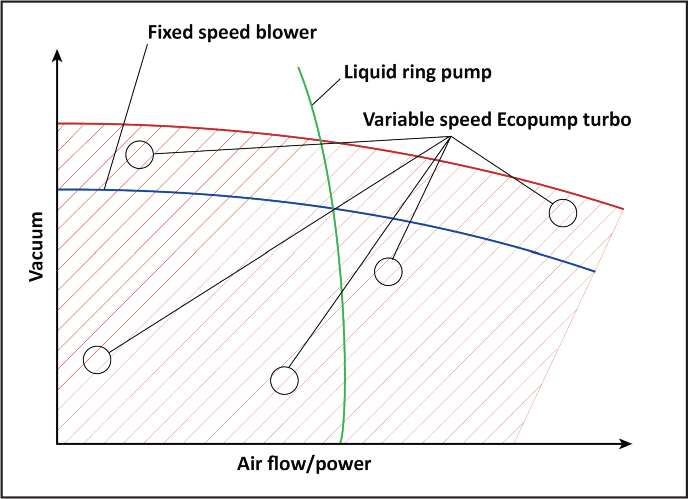

Operating window comparison.

Operating window comparison.RUNECO SOLUTION—OPERATING PRINCIPLES

There are some principles which govern the content and operation of an efficient and eco-friendly vacuum system. The primary function of a wire and press section, i.e., the removal of water, needs to be carried out effectively and reliably. This requires speed-controllable turbo blowers to create the needed optimal vacuum level, robust dewatering equipment such as save-alls and doctoring, and means to measure all this reliably to get the feedback for the energy-efficient control of the system.

Vacuum is created as a result of moving air across a restriction. Fans, turbo blowers and liquid ring pumps can each be used to achieve this goal and are also often used in combination with each other. Turbo blowers have the benefit of being an inherently efficient way of compressing air for the modest compression ratios (less than 3.5) faced in a paper machine. A turbo blower is, for a given rotational speed and impeller design, a constant compression ratio device as opposed to a liquid ring pump, which is a constant displacement machine. The power consumption of a turbo blower is a function of the air flow that is being compressed to satisfy the pre-determined compression ratio. A constant speed turbo blower has a limited range of efficient operation since the paper machine vacuum adjustment outside of the designed level requires throttling.

EP Turbo Blowers are designed to operate efficiently across a wide range of vacuum levels and air flows. They allow paper mills to optimize vacuum levels. High speed motors, driven by frequency converters, allow a typical RunEco blower to provide paper machine vacuum levels between 30 and 70 kPa. A wider range of impeller designs allows highly efficient levels across the operating range. This means that the amount and the usage of throttling valves can be reduced to a minimum. The result is energy savings of 30 to 70 percent when compared with traditional vacuum systems.

HYBRID VACUUM SYSTEM

A typical Runtech RunEco vacuum system consists of several smaller size turbo blowers giving clear design and operational advantages over the competition. It also offers liquid ring pump technology to form a combination of both technologies—namely a hybrid system.

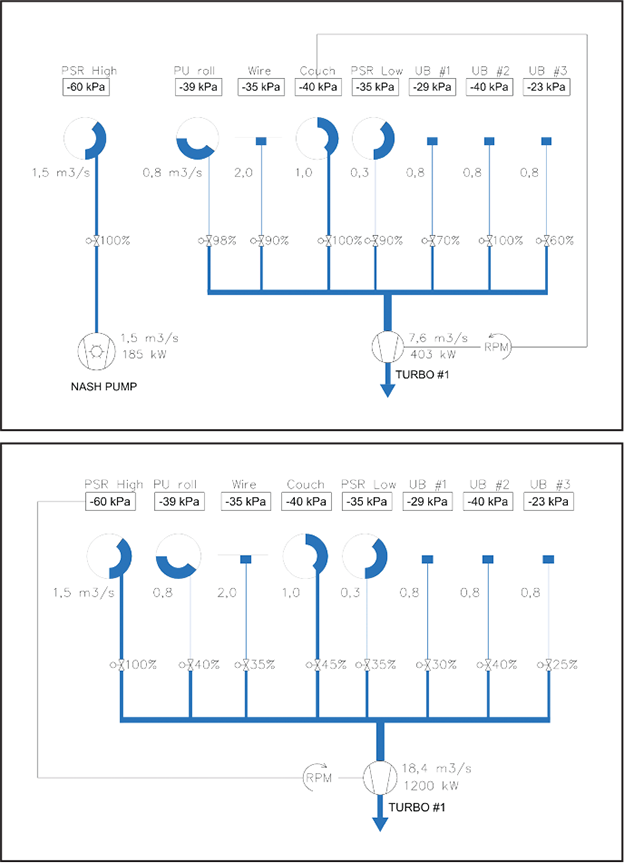

Often, a single or a few low air flow consumers (devices) are operating at high vacuum levels, such as a high vac box or a press suction roll high vacuum zone, while the rest use a considerably lower vacuum level. This leads to a situation where the most economical option is to continue the use of the existing liquid ring pump (LRP). Fully rebuilding a system with blower technology is not always the most efficient solution, especially if this means that different vacuum levels need to be combined in one blower. It is proven that a well maintained LRP operating at low speed to produce high vacuum level can perform at a good efficiency level, outperforming systems where a large single blower experiences considerable expansion losses.

Vacuum demand varies for different paper grades, felts, and machine speeds; therefore, a tailor-made solution with flexible and variable capacity can balance the supply and demand, resulting in both optimized dewatering and minimized power consumption. Paper machine vacuum levels are measured at the vacuum pumps and blowers to identify problem areas. The dewatering elements such as flat boxes, save-all pans, and uhle boxes are also reviewed. Specialists study pressure and bleed losses to analyze the energy consumption and evaluate if the vacuum levels are too high.

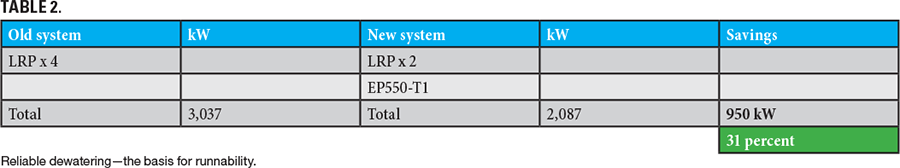

In the following rebuild cases, existing liquid ring pump or pumps are compared with a hybrid system to find an optimal balance between investment and operating costs.

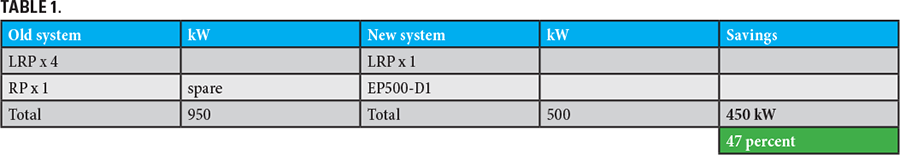

A tissue producer gained energy savings of 447 kW, which was almost 50 percent of its previous usage; water usage decreased by 75 percent. The installed EcoFlow dewatering measurement system provided a better control of the process.

A confidential tissue producer kept two liquid ring pumps for the chest box. A RunEco EP550-T1 Turbo Blower was connected to other vacuum consumers to allow all energy efficiency targets to be reached.

Each vacuum element in the machine, such as a suction box or a suction roll, requires a certain amount of air flow to operate at an ideal vacuum level, i.e., at the minimum to maximize the energy efficiency while maintaining the runnability and dewatering capacity. The needed capacity is dependent on felt life and type, paper grade, basis weight, machine speed, etc. To achieve this challenging goal, we need reliable dewatering measurements. The water that is removed from the paper sheet is a multiphase flow containing solid particles as well as air, thus being often subject to foaming. Traditional magnetic liquid flow meters demand a homogenous flow and often will not be able to provide continuous accurate data from such variating circumstances. Runtech EcoFlow™ meters are designed to measure water flow across a mechanical restriction and are not sensitive to entrained air or foaming. These devices are used both under vacuum (in a separator drop leg) and in atmospheric conditions.

The third fundamental issue in an energy efficient vacuum system is the dewatering and doctoring. These are not only related to energy consumption, but also play a major role in paper machine runnability (profiles), efficiency (dirt and breaks) and profitability. Therefore, a well-designed and operated dewatering and doctoring system is one of the key issues to a well-performing and energy-efficient machine.

The most economical method of water removal in a press section is nip dewatering, as opposed to felt dewatering requiring higher vacuum levels and thus energy demanding higher air flows. Fit-for-purpose doctoring and save-all equipment allows the felts to run wet collecting water in the pans, enabling higher dewatering, higher felt lifetime and, for example, better moisture profiles to improve runnability. Suction rolls are often equipped with double doctors to prevent re-wetting and maximize void volume to allow best water removal. Save-all pans should be designed to manage the water that is removed from the nips, and engineered to be rigid enough to accommodate doctor holders. Runtech is one of the leading suppliers for the improved dewatering and doctoring solutions for all kinds of pulp, paper, board, and tissue machines. In many cases, Runtech’s solutions have led to a 1-3 percent increase in dryness after the press section, which saves a considerable amount of energy in the dryer section (4-12 percent less steam).

TAILOR-MADE SOLUTIONS—NO COMPROMISES

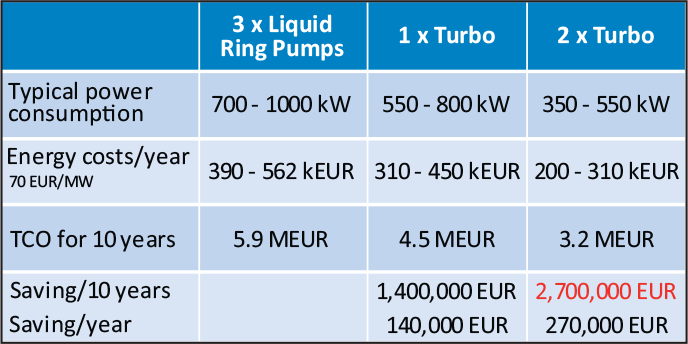

Depending on tissue machine design and width, the most efficient operation sometimes requires one or two turbo blowers. The specified air flow capacity is typically quite high, consisting of overall safety margin, felt life, and type margin, and with liquid ring pumps, e.g., pump wear and seal water temperature variation margins. In normal operating conditions, the needed air flow capacity is ∼40…50 percent lower than the specified capacity. Regardless of the situation, a RunEco system with a fully speed-controlled turbo blower provides high operating efficiency at all times.

During normal operation one single-stage turbo blower typically provides sufficient capacity. However, a system with two turbo units allows even higher operational flexibility, controllability, and energy efficiency. As an example, tissue machines often have three main vacuum consumers, namely the press suction roll and two felt uhle boxes. Also, the vacuum level of the suction press roll is often clearly lower than that of the uhle boxes. And as air is a compressible medium, the volume changes significantly with the surrounding pressure. These unavoidable facts lead to considerable energy losses in a one-unit system through two mechanisms: 1) throttling losses in the suction press vacuum level control; and 2) air expansion from the lower suction press roll vacuum state to the higher vacuum in the felt uhle boxes and in the main vacuum header. An often-used vacuum level difference of approximately 10 kPa between the suction press roll and felt uhle boxes can lead to a more than 30 percent increase in the air volume through expansion and thus a large increase in the energy consumption.

A two-turbo blower RunEco system, while offering a redundant air flow capacity, also offers a higher degree of controllability and less losses resulting in a more energy efficient vacuum system. Typical savings in energy consumption are 30-50 percent when the losses are eliminated in a two-turbo system. Another advantage is the existence of a back-up in the very unlikely malfunctioning situation, as the machine can be run with one turbo unit only, though sometimes with less efficiency.

Fully rebuilding a system with blower technology is not always the most efficient solution, especially if this means that different vacuum levels need to be combined in one blower. In rebuild cases, an economical solution, with suitable airflows, can also be a hybrid vacuum system combining existing LRP with a new turbo blower. The LRP continued to be used for the higher vacuum uhle boxes and/or to assist the turbo blower with higher airflows after a felt change. In a case where the uhle boxes can be operated with moderate vacuum levels, close to the suction press roll vacuum, the LRP can then be stopped during the normal running period and used only for abnormal airflows such as experienced with new felts.

DISCOVER THE POTENTIAL OF YOUR MACHINE

Vacuum demand varies for different paper grades, felts and machine speeds, therefore, a tailor-made solution with flexible and variable capacity can balance the supply and demand, resulting in optimized dewatering and minimized power consumption. Vacuum levels are measured at the vacuum pumps and blowers to identify problem areas. The dewatering elements such as flat boxes, save-all pans and uhle boxes are reviewed. Specialists study pressure and bleed losses to analyze the energy consumption and evaluate if the vacuum levels are too high.

With the experience of thousands of audits and dewatering studies at paper mills, we are able to benchmark the effectiveness of existing vacuum systems, dewatering equipment, suction elements, fabrics and felts.

Today, over 900 turbo blowers have been sold globally. This experience and expertise allows us to work with our customers, help them get the most out of their papermaking process and vacuum systems, and ensure they achieve both their operational and process goals.

REFERENCES

Lee & Man Tissue TM 9, 10, 11 & 12 are new double-width tissue machines installed in the Guangdong site in southern China. All machines are equipped with two EP500-D1 turbos to fulfil the capacity and enable controllability. Installed power in all cases is 1000 kW; however, with the help of EcoFlow dewatering equipment the machines have been optimized to run only with one unit during normal operation having an energy consumption between 300-350 kW.

All energy consumption targets have been fulfilled and the efficiency has been increased even further with an exhaust air heat recovery system. In addition, turbo systems are naturally running without any sealing or cooling water.

Lee & Man Tissue TM 3 was a vacuum system rebuild project for a double width tissue machine in the Ruichang site in central China. In the existing system there were three liquid ring pumps consuming altogether ∼800 kW. The new system was rebuilt with one EP550-T1 turbo unit replacing all the pumps.

After start-up the turbo operation was optimized with the help of EcoFlow dewatering equipment enabling a reduction of ∼50 percent of the energy consumption during normal operation. All energy efficiency targets have been reached and sealing and cooling water consumption fully stopped.

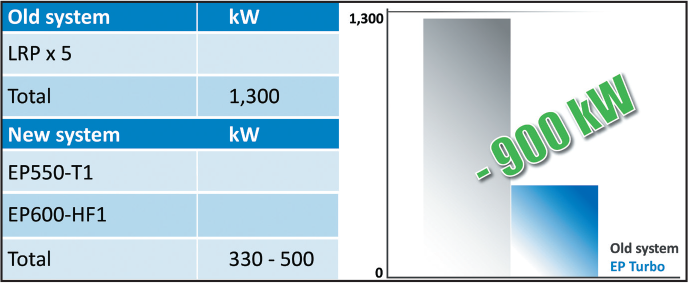

Confidential tissue machine TM 11 is a double width tissue machine in Europe. A vacuum system rebuild project was started to improve energy efficiency and improve profitability. The old vacuum system consisted of five liquid ring pumps consuming altogether ∼1300 kW. The new system was rebuilt with two EP blowers, EP550-T1 and EP600-HF1.

After start-up the turbo operation was optimized with the help of EcoFlow dewatering equipment, enabling a reduction in the energy consumption up to 900 kW during normal operation. All energy efficiency targets have been reached and sealing and cooling water consumption fully stopped.

Paper 360

Paper 360