Paul Richards, senior technology manager, Tissue

Stefano Marenco, director, PrimeLineTIAC and R&D Tissue

Joseph Guadagno, vice president, Tissue and Air System, North America

Can you give an overview of the Andritz TAD concept, including anything interesting about the development timeline?

Paul Richards: Andritz only entered the TAD machine market in mid-2000, following the breakdown and closure of the Beloit Corporation. Whilst others looked to acquire the technology, Andritz focused on the experience of the personnel in an effort to further grow into the TAD market, and the US market in general. Over the next two years, a concept was conceived and engineered and by early 2003 Andritz had its first order for a TAD machine.

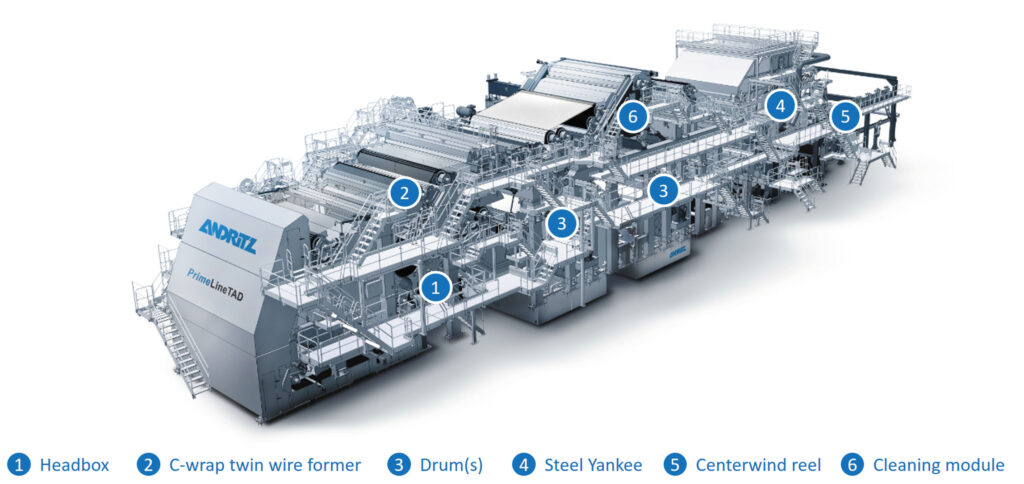

The Andritz PrimeLineTAD comprises a 2- or 3-layer headbox with dilution control that delivers the stock to a modified C-wrap twin wire former. The former is adapted to allow vacuum assisted dewatering of the base sheet before the sheet transfers to the TAD section. At the pick-up, there is the possibility to run a speed differential to tailor the quality and sheet structure according to customer needs, before the sheet passes over the “shaping” or “moulding” vacuum box to lock in the sheet structure. Next, the sheet is dried over two TAD drums in series, up to anything between about 75 percent and 90 percent dryness depending on the needs of the specific customer. The TAD drum is a patented design, with a fully welded stainless steel construction that supports the TAD fabric and sheet during the drying process. The complete air handling system has been developed and engineered using computational fluid dynamics analysis (CFD) by our North American colleagues in Canada.

The sheet is then transferred to the Yankee cylinder for application of dry crepe before passing over the recently developed and patented active air foils and being wound using the linear center-wind assisted reel.

A number of the technologies have been specifically developed for the TAD product. These include the 3-layer headbox, the TAD drums and their air-systems, the active foils and the center-wind reel. Additionally, the C-wrap had to be modified to allow the use of vacuum assisted dewatering in the former.

When we first started down this route, we typically offered a single large diameter TAD drum, but have since developed our standard machine to the two drum arrangement to optimize the overall energy efficiency of the process for our customers.

Can you talk about the challenges customers face when producing premium quality tissue?

Joe Guadagno: The biggest challenges for most newcomers to the TAD business are quite honestly the levels of complexity of the process compared with conventional tissue making. That, of course, plus the fact that the machine is more than twice as long as and, therefore, more expensive than, a standard light dry crepe (LDC) tissue machine. The level of papermaking competence required is high and the personnel with experience are not as readily available on the employment market as for, say, LDC production. Moreover, the TAD side of the tissue industry is particularly secretive, with all manufacturers carefully guarding their know-how. This means movement of personnel from one manufacturer to another often will have contractual obstacles or barriers to making a new start.

A second issue for TAD is the overall bulk of the product. This is the biggest advantage for TAD products, but means that transportation is a potential cost problem. TAD needs to be produced close to the market to avoid transporting high bulk, low weight materials, when shipping costs can start to seriously influence overall production costs. The other big issue for TAD producers is the overall energy demand. Through-Air drying uses a large amount of thermal energy, which is typically generated using gas burners. In many regions of the world, the infrastructure cannot support such demands and so alternatives would be needed.

In theory, just about anybody could produce TAD if they already have some papermaking experience; it is more a question of having a suitable market for the final product. To be attractive, the customer needs to be willing to pay a small premium for the “premium quality” produced. In many regions, there is a strong reluctance to accept this requirement and, as such, it becomes difficult to justify the levels of investment and, historically, ROI calculations have thus been unattractive.

Who would be the ideal customers to benefit from this technology?

The ideal customer needs to already have a good basis for operation. It must not necessarily be in tissue, although this helps to ensure there is a trained workforce available. The process is bigger than conventional LDC and needs more personnel to work the machine from pulping to reel. Although the product is not very heavy for the roll size, the frequency with which the parent rolls leave the machine requires an investment in roll handling to ensure rolls are swiftly processed and fed to converting.

Such customers also need a sound awareness and experience of the converting of tissue. It makes no sense economically to ship paper to a converting plant and have it converted off-site. Key personnel with operational capabilities, especially in the area of controls and automation, together with dedicated maintenance resources with proper levels of materials (spare and wear parts) will ensure the process is kept running at the highest efficiency.

Given the foregoing, the ideal customers are those that already have such operations, but everybody has to start somewhere, and Andritz—based on its long-term expertise with TAD technology—can support through this complete development phase (when the machine and process are brought into commercial operation) with know-how, equipment, training, assistance, and services.

Can you go into detail about the technology (the hood and air system) and what sets the Andritz PrimeLine TAD concept apart from competitors?

Joseph Guadagno: The TAD Hood and Hot Air System consist of important equipment that defines the TAD system’s thermal drying process. All components must be carefully selected and optimized to allow the TAD drying process to operate efficiently through the range of parameters needed for tissue and towel grades. The process air system is used to transport hot air through the paper sheet with a uniform temperature and pressure profile. There are different ways to properly mix the air and optimize the supply air temperature and pressure profile uniformity to the TAD drum. For this purpose, we developed specially designed static mixers, guide vanes and perforated screens that are incorporated into the ductwork and the TAD supply hoods. Our extensive experience in air systems engineering, both from field installations and from using CFD analysis for optimization, has allowed us to excel in this area. The air system layout must not only be carefully designed with minimum space consideration, it must also address energy efficiency, air flow simplicity and component accessibility. All these factors have a direct impact on installation and operating costs.

The process air is transported through the large insulated ductwork by the variable speed supply fans that deliver the required air mass to the sheet. A natural gas-fired burner is installed after each TAD supply fan to heat the air supplied to the sheet and to increase its drying potential. The burners are selected to operate with low CO and NOx emissions throughout their design firing rate. The PLC-based control logic monitors the burner firing rate, and ultimately the TAD supply air temperature, for the various system operating modes.

The supply air ducts are connected to the TAD hood modules with articulating joints that permit the TAD hoods to retract, allowing access during fabric change, sheet breaks, or cleaning and inspections during maintenance shutdowns. The wet and dry end TAD hoods are constructed of two independent, retractable halves, with perforated nozzle plates that allow proper airflow distribution into the space between the TAD hood and TAD drum. The supply air is “pulled through” the sheet by negative pressure within the TAD drum.

Moisture removed from the sheet is then partially evacuated to the atmosphere using the TAD exhaust fan. The air exhausted to the atmosphere is replaced with fresh air make-up. The TAD supply fan pushes the TAD return air back into the pre-dryer supply air duct system in this continuous drying cycle.

By controlling the TAD supply air properties like mass flow, temperature, and absolute humidity, we optimize the drying capacity of the system. With the proper control of the exhaust air pressure, moisture, and temperature, the optimal energy use can be achieved together with extended life of TAD fabrics, both of which represent a significant operating cost.

Of course, various types of heat recovery can be implemented to reduce overall energy consumption. We have implemented several types of heat recovery options, such as air-to-air, air-to-water, turbine and vacuum blower exhaust for pre-heating air, and several other solutions. Our goal is to make the highest quality tissue and towel products with reduced energy input.

Can you talk in-depth about energy savings, and perhaps provide some numbers?

Paul Richards: TAD by its very nature is extremely energy intensive, which is one of the key reasons the market has developed so much in the USA, where energy is traditionally so much cheaper than in other regions. What we are seeing today, however, is an interest from regions where energy is much more expensive, but where a market can still be developed if a way can be found to reduce the energy impact.

Historically, TAD was made with a dryness after the TAD of around 95 percent—one of the reasons that led to the development of the UCTAD, or Un-Creped TAD, process. The Yankee, a traditional part of any tissue machine, was only really a carrier, allowing a percentage of dry crepe to be put into the end product. Today, depending on the technology being used and the manufacturer, the dryness after the TAD can be significantly lower. In fact, we and our customers are constantly looking to push these boundaries and are evolving with the chemistry suppliers to allow higher moisture to the Yankee. This movement of the drying balance is a major step in reducing the energy demand for drying.

From the time of the development of our first TAD machine to the current offering, we have reduced the drying energy demand in the region of 15-20 percent by the simple use of a second TAD drum, albeit smaller diameter drums. This allows a much more controlled and targeted use of the hot air in the drying process. We can use much hotter air for the first air system, which also has a lower permeability of the tissue sheet, where the pressure drop is considerably higher. Then, in the second system, where the sheet is drier and more open, we can use lower temperatures and higher volumes. All of this protects the other system components, such as the TAD fabric, whilst allowing smaller overall system components and commonality between the system sizes.

Taking this line a little further, our drive is now to further push the balance of the drying toward the Yankee, with a target around 65 percent max solids to the cylinder. This can only be achieved in conjunction with our customers and our partners in the chemical side of our industry. Financially, however, if such a movement can be realized, then the energy efficiency of the drying process could finally be at an optimal level. Once all the “free water” has been removed, and only intercellular water is left, the impingement process is much more efficient from a drying perspective.

Another recent addition to energy saving opportunities comes from developments in vacuum technology. Using blowers instead of traditional liquid ring pumps provides a hot air source that can be used for pre-heating a portion of the incoming air as it enters the system.

Another possibility, probably more popular in places where gas supplies are more limited or infrastructure is not yet available, is the use of steam (heat exchangers) as a heating medium. The system temperatures lend themselves to consideration of such heat exchangers, especially in situations where an excess of steam is available, such as near pulp plants etc.

Can you also go more in-depth on fiber savings?

Paul Richards: When we talk about fiber savings we need to be a little careful. A ton of paper is still a ton of paper, whichever way you look at it. The key is, however, that the yield of finished (converted) rolls for a given end diameter is much higher, due to the much enhanced caliper (or bulk) of the finished sheet. Depending on what the goal of a given customer is, they can either manufacture a lighter basis weight base sheet or they can convert more rolls of the same basis weight. Either way, there is a saving of fiber for the same number of finished rolls, or a higher number of finished rolls for the same weight of paper. Both solutions create a path to more profit potential if all other economic factors are met.

Can customers see the TAD concept in action, and see some samples produced of their own products?

Paul Richards: The PrimeLineTIAC (Tissue Innovation and Application Center) pilot machine at our facility in Graz, Austria, is currently configured in TAD mode. Now would be the ideal time for customers to see what TAD can do for their markets.

Stefano Marenco: We are actually running trials with our customers and one of the main purposes of the trial is to produce paper reels (small rolls of 600 mm width) that are then converted by the customer into the final products. The tissue makers can then run market analysis and product quality tests to predict the interest of the consumer or market potential for a new product.

The actual restrictions imposed by the coronavirus are not helping our clients to freely travel and supervise all the trails. In some cases, where no personal presence was possible, our Andritz IT and automation personnel could support our customers with virtual meeting and assistance tools that make the trial experience as integrated as possible.

Can you talk about any references?

Stefano Marenco: Customer trials are highly confidential and are protected by various nondisclosure agreements. We can tell you that we are testing some new technologies in TAD mode and the results are promising at this stage. New ideas have also been developed for new products with unique quality aspects and the trials schedule is quite tight at the moment.

Can you tell us about any ongoing R&D work on the TAD concept?

Paul Richards: One of the key areas of interest in this technology is clearly a reduction of the drying energy. Much of the current effort is directed at how best we might achieve a reduction of the overall drying energy without increasing the net energy input. Obviously, our goal here is to make deep cuts into the overall net energy. Perhaps key to this is increasing the sheet solids ahead of the first TAD. This is where the largest gains in thermal drying energy reduction can be made. The question is only how much energy we have to put in elsewhere to increase the solids.

Stefano Marenco: We are also focusing our research on technical solutions that can increase the overall efficiency of the TAD machine with a more compact design in order to reduce the building footprint and the civil construction costs for this technology.

For more information, please visit www.Andritz.com/tissue or contact us at [email protected]

Paper 360

Paper 360