Tolfsson has been working as the head of R&D Tissue at Valmet’s center of tissue research and development in Karlstad, Sweden for the last 10 years and has seen many new developments emerge from initial ideas and turn into valuable, working concepts and products. But how has R&D in tissue production changed over the years, particularly as we enter an era of a much more environmentally aware customer, as well being at the dawn of an autonomous world? And what should we look out for in the future of tissue making?

T360°: How has R&D in the tissue industry evolved over the last few decades?

Tolfsson: When compared to 25 years ago, R&D at Valmet has completely changed. In the late 90s and early 2000s, the focus was very much on the mechanics of the machines and being the top supplier when it came to mechanical design. We tended to leave the process knowledge side of things to our customers; they were the experts in that department. But now process knowledge plays a much more important part in our R&D activities. We have now also become experts on how to run the machines, which paper properties are needed, and how different properties effect energy use, runnability, and efficiency of the machines.

We are also partnering much more with our customers, listening to their needs, feeling their pain, testing out their ideas. This we do both at their sites and on our pilot machine in Karlstad.

One thing that stands out when working in the tissue industry is the sheer diversity of products from the different regions of the globe, so we find that we also have to have an equally diverse knowledge bank when it comes to R&D.

Who drives the innovations in R&D? Does it come from internally at Valmet, or from your customers?

That’s a good question, but actually it’s both. When it comes from inside, it is usually reflecting what the customer is going to need in the future; for example, lowering the carbon footprint or making sure to keep on the right side of environmental legislation. But quite often we have a surprise from a customer, something that really challenges us, like trialing a new raw material.

This is where the pilot plant comes into its own, and we get the opportunity to work on projects together with our customers. This is an exciting way of doing R&D as we often stumble across new ideas that can be beneficial for all our customers, and sometimes the whole industry.

What trends are you noticing in the industry in particular when it comes to your R&D work?

What are your customers asking for? We are definitely seeing demand increasing for higher quality products, particularly in Europe, China, and the rest of Asia. So of course with our range of machines we can satisfy pretty much any need when it comes to high quality.

But the real trend we are noticing is that our customers are demanding much more efficient machines when it comes to production and fiber, energy, and water savings. One of the areas we pay very close attention to when it comes to machine efficiency is runnability. The fact is you can have a highly energy efficient machine, but if a lot of paper is going into the pulper, then what is the point? A well-running machine that is producing high quality tissue is a great tool for the producer because all areas of production improve.

So at Valmet we design all our machines to be as energy and raw material efficient as possible, at the same time as making sure that there is as much quality product on the reel as possible. That is how we make all the numbers add up when it comes to carbon footprint and sustainability. Good runnability is a crucial part of our R&D work.

Another trend we are noticing is that the emphasis is moving away from “tons on the reel,” particularly in China, where our customers are looking for higher qualities using our TAD or hybrid machines. It’s like flicking a switch, the change has come so quickly. It is much more now about surface area than tons when looking at production numbers.

What are the main challenges you see your customers facing at the current time?

Apart from the pandemic, the tissue industry is faced with various challenges at the moment, including the fluctuation in pulp and energy price rises. Energy is perhaps the most serious challenge, particularly for those producers that are still using older machines which are not very energy efficient, so they will not be able to absorb the price rises.

There is a huge difference in energy and water use when comparing a tissue machine designed in the 90s to a modern machine. Even though the 90s does not seem that long ago, a modern machine now will have half the energy consumption of a 20-year-old machine, and water consumption will drop by as much as 80 percent. Developments on tissue machines have come a long way in a short space of time.

There is no-doubt that having a modern fleet of machines in the current climate is a huge advantage. As an effect of this we see a huge demand for our Advantage ViscoNip press for rebuilds, for example.

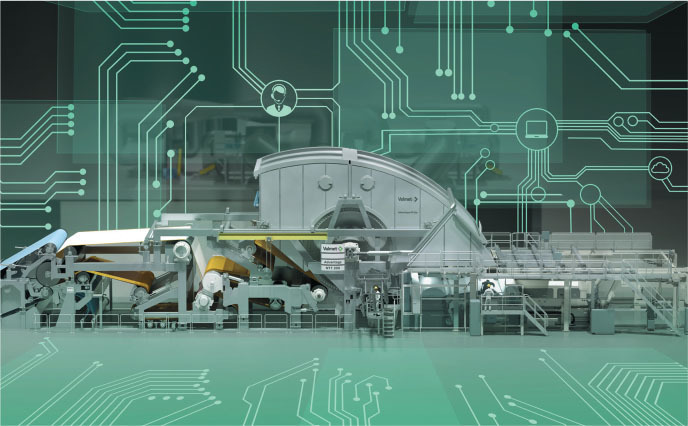

How important is digitalization becoming to Valmet when talking about tissue production?

This a big focus at Valmet and we are using the Industrial Internet across the production process all the way to converting—from being connected to machines to following performance or spotting potential issues before they become serious. At Valmet, we want to help our customers to monitor what’s going on in the machine and look out for ways to avoid unplanned shutdowns, and analyze performance.

We are also in a very good position to understand and compare energy and raw material efficiency and help customers apply best practices across the fleet of Valmet-delivered machines. Through process expertise and data analysis, we can identify the sweet spots and find out where things are going well and what needs to be improved in the tissue machine or the production process.

A lot of our work at Valmet involves simplifying the data management so that everyone can easily understand what the data is telling them and then how to act. There are around 10,000 signals coming continuously from a tissue machine, and production managers and operators need intuitive tools to help them solve problems and make adjustments in as little time as possible.

What work are you doing at Valmet on fibers other than wood for tissue production?

This is a really important area for us at Valmet, and we believe we are going to see a major change in the industry where we will be using more fiber sources that are based on annual growth cycle as opposed to the longer growth cycles of wood fiber. We believe we are going to see limitations in the future when it comes to wood fiber use in tissue, particularly as tissue tends to be a single use product. We are already seeing an increased use of bamboo, which is an excellent choice of fiber for tissue production. Bamboo is fast-growing, and in terms of quality and how it handles on a tissue machine, it is equal to wood fiber.

Besides bamboo, we are seeing bagasse as a raw material being widely used, and in Europe and North America straw is being used more and more. Compared to wood fiber and bamboo, these are completely different fibers, so they are not substitutes and call for a lot of work on how we handle them to get the most out of them.

No conversation involving business or industry nowadays would be complete without acknowledging the effects of Covid-19 on operations and activities. Can you tell us your own experiences relating to the pandemic?

The pandemic has led to a lot of extra activity in the tissue industry when it comes to our customers. Take North America, for instance, where there was a huge rise in consumption; in fact, there was well publicized “extreme consumption” at the start of the pandemic. We guess that every single jumbo roll will have been pulled out of storage and been through converters at producers in the US to deal with the increased demand!

From a machine supplier point of view, including R&D of course, we have had our challenges due to the pandemic; we are a global operation, and have customers spread all over the world. Our customers need our expertise in greenfield operations, new builds, rebuilds and start-ups.

When the pandemic started, we of course utilized our performance centers and local resources to support when it was difficult to travel. Fortunately, even before the pandemic we were already strongly developing our remote services and digital tools and they really came into use when the virus struck. In fact, I think it has become quite clear that digital services and tools will remain in place post-pandemic as we have all realized that people travelling around the globe is not always necessary to keep machines and mill operations running smoothly.

Paper 360

Paper 360