MARK RUSHTON

Consumers now really ‘get’ the fact that fiber-based materials are environmentally-friendly alternatives to plastics when it comes to packaging. However, this is not simply a case of brand owners and supermarkets swapping one for the other; plastics have many features that fiber-based packaging simply does not have, at least at the moment. This is where R&D in chemistry comes into the forefront: in the future, chemical R&D success stories will drive the fiber-based packaging industry forward and will hold many answers in the quest to find more sustainable alternatives to plastics.

“Even now, in a lot of cases, fiber-based materials can provide an alternative to plastic-based packaging,” says Reetta Strengell, director of R&D and technology, Kemira. “However, replacing plastics in packaging is not a simple task. Without chemistry, packaging board would not have the required properties, such as stiffness, strength, or formability. In addition, all food packaging needs to be hygienic and seal proof, good for protecting food and preventing leakage. So, in R&D at Kemira we are doing a lot of work, for example, on barrier coatings to create resistance to grease and liquids, to find other new solutions to improve the functionality of fiber-based packaging, and to ensure that it meets high standards for hygiene.”

Finnish-based Kemira has been operating in the chemicals business for almost 100 years and is now one of the leading companies supplying chemicals right across the industry, from pulp to paper, board, and tissue. Chemistry is there from the start of the manufacturing process, bleaching the fibers, making them easier to pulp, and treating process and waste waters. It also gives functionality to the end products.

The world of chemistry in the pulp and paper industries contains vast areas of expertise, with many different specializations, Strengell says. “There are many interesting things going on in R&D. We are working on replacing fossil-based raw materials and products with more bio-based ones, as well as finding ways of utilizing valuable components from process side streams in our products. Regarding packaging, we have also been successful in the trends toward lightweighting and increasing strength.”

When it comes to packaging for food, there are stringent regulations, and one product certainly cannot be simply replaced by another. Strengell says, “While this is a time of fantastic opportunities for fiber-based packaging, there are strict requirements and regulations, in particular around material in contact with food. If, say, we come up with a new molecule, it must be tested and certified. Anything new needs to be proved as absolutely safe before it goes into production and use.

“In addition, it needs to be tested for runnability. It’s great to have a new barrier coating solution as an alternative to plastic, but if it doesn’t work properly on the paper or board machine, or go through the converting line, then that’s not so great,” she explains. “Runnability and functionality are really important when it comes to chemical solutions, so it can sometimes take a lot of time and effort to get from R&D to final products.”

FOOD PACKAGING CONSUMER SURVEY

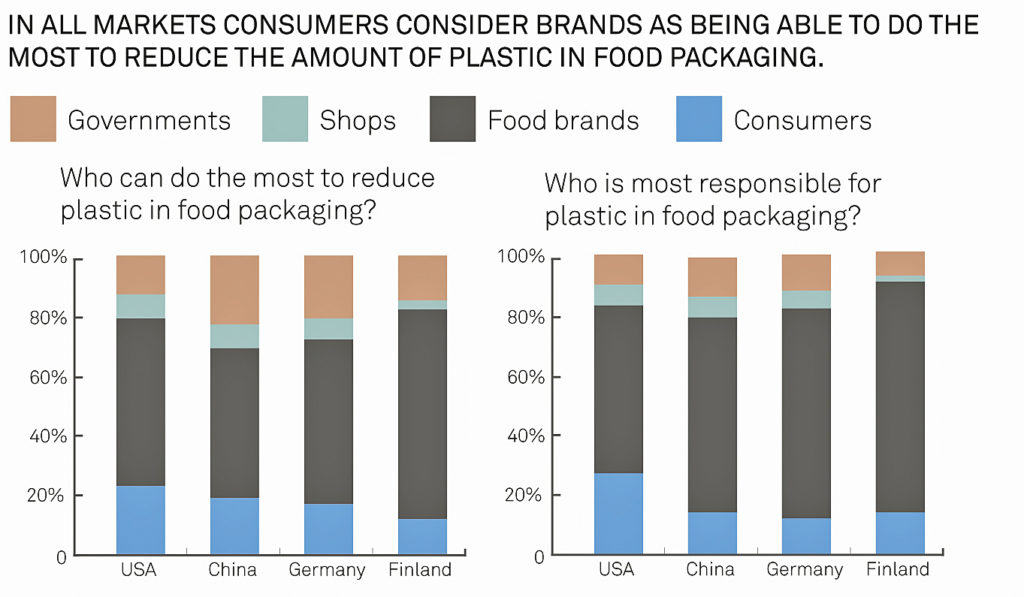

As a major chemical supplier to the pulp and paper industry, Kemira is a vital part of the packaging value chain; therefore, end-user behavior, demands, and wishes are massively important in terms of the company’s future vision. It recently commissioned an in-depth, independent consumer survey on food packaging in some of the main markets it supplies to: China, Finland, Germany, and the US. Altogether, 4,044 adult individuals were surveyed about their views and attitudes toward food packaging, plastics usage, and renewable materials.

The survey dug deep into consumer attitudes and everyday choices in the various countries, with questions including how often respondents cook at home, shop for groceries, and buy ready-made meals. They were also asked about the importance of different features of the food packaging itself and how these affect the decision to buy the food product. For instance, is the packaging too large for the food inside? Is it protected enough? The survey also asked respondents about the roles of different actors—i.e., who is most responsible for the plastic in food packaging?

The consumers’ answers make for fascinating reading; for instance, the survey revealed that a large number of those surveyed would be willing to pay more for food packaging that was made from renewable resources. In the case of China, 85 percent of respondents said they would pay more. It also revealed that a high number of those surveyed in Europe in particular would view increased plastic in packaging as a negative development.

The survey also revealed recycling habits of the four countries, with the citizens of Germany being the highest recyclers and those in the US the lowest.

“This survey concentrated on the consumers, their attitudes, what they want out of their food packaging, but also what they expect,” says Strengell. “We can clearly see that there is currently a real switch going on regarding consumer choice. They want sustainability built into the products they are buying, and that includes the packaging that their chosen products come in, and brands are recognizing this. The survey finds that consumers are willing to pay more for sustainable packaging. But it is interesting to note that the key consumer priorities for the food packaging itself are also related to functionality, such as the hygiene and leak-proof properties of the container.”

Kemira’s full International Consumer Survey can be downloaded here: https://www.kemira.com/insights/we-asked-consumers-about-food-packaging/

Kemira and Chemicals from Renewable Sources

Kemira is also looking closely at developing its own 100 percent bio-based chemicals for paper and board production. It recently signed up to a four-year EU-funded project that aims to develop chemicals from renewable raw materials, as well as develop new ways to improve production efficiency at pulp mills with higher utilization of wood biomass.

The project, which launched in May 2019, has received a EUR5.9 million (US$6.5 million) funding from the Bio Based Industries Joint Undertaking. During the next four years, Kemira will work with other project members to assess the technical and economic feasibility of potential bio-based offerings produced from a demonstration-scale pulp mill in Europe. The final aim is to develop fully bio-based polymeric chemistries for paper and board production to complement—and ultimately replace—polymers that are derived from fossil fuels.

Paper 360

Paper 360