Author: Thomas Holm – Buckman

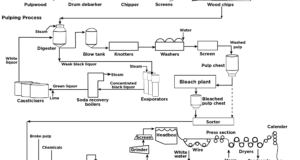

In the late 1990s, the Paper Industry was confronted with the issue of dioxin formation in the effluents of some of their bleach plants. Dioxin formation in the bleaching of wood pulp via the use of chlorine was documented. The industry began using chlorine dioxide, which provided significantly less formation of dioxin. Next the industry started to use oxygen delignification to reduce expensive chlorine dioxide usage, and in an effort to reduce it further, the use of enzymes for pulp bleaching was investigated.

During the early 2000s, mill trials began using a blend of xylanase and cellulase enzymes to reduce the amount of chlorine dioxide. A narrow operational band of pH and temperature had to be maintained over a period of 1-3 hours for the enzymes to be effective. Unfortunately, the required conditions were not native to the typical pulp mill, so pH and temperature control strategies had to be employed. Typical pH at the end of the brownstock washing system is between 9.0-11.5, causing the need for acidification to achieve the required 6.5-7.5 pH range. The acidification of this pulp proved to be problematic as residual lignin would reprecipitate causing more issues than could be overcome with the enzymes. There were also safety issues as hydrogen sulfide gas would be released. Some mills had limited success, but for the most part, the concept of bleaching enzymes was abandoned. For the mills that could implement the process, there were issues with yield loss. This was because the enzymes used contained a significant amount of cellulases which caused unwanted breakdown of the cellulose.

Recently, the technology of enzyme isolation and production has changed so that a new generation of materials warrants a closer look. We have been able to produce enzymes that perform in a higher pH regime and purify them to remove the cellulases. These new enzymes can operate at pH up to 10.0, at higher temperatures and shorter retention times than their ancestors. This has opened up a new opportunity to not only reduce bleaching costs through the reduction of chlorine dioxide, but also to produce a less toxic effluent.

This new generation of enzymes is being applied in bleaching with excellent results. Several mills have commercially adopted the technology. The dissolution of xylans before bleaching allows a mill to remove additional lignin compounds attached by a hemicellulose matrix and wash them out of the system before the introduction of chlorine dioxide. Many mills are experiencing a 10-15% reduction in total chlorine dioxide usage, and in some cases, as high as 30%. In addition, the removal of lignin and ferulic acid associated with xylans is assisting in the reduction of the “b” value (or yellowness) of the final pulp(1). This can result in the reduced usage of optical brighteners in the final paper product. The dissolution of xylans has also been shown to reduce overall brightness reversion; therefore, less bleaching chemical is needed to maintain brightness targets. Multiple mill trials have shown that xylan removal by enzymes has no significant impact on paper properties. A sample of beater curves, with and without enzymes, appears in Figure 1. The removal of surface xylans has had no significant impact upon paper properties. End user characteristics in graphics papers have also been studied, and no ill effects have been found from paper produced from enzymatically treated pulp.

Figure 1: Impact of enzymes upon standard beater curves (PFI revolutions)

Another concern with the use of enzymes is the release of additional BOD/COD to the treatment plant. Enzymes do increase the release of organic material, and in a mill where there is a prebleached washing stage, this organic loading is sent back to the recovery system. The net impact in these systems is a reduction in BOD/COD loading from the bleach plant. One mill has experienced a 14% reduction in effluent BOD. In cases where there is no prebleached washing, enzyme activity will cause an increase in BOD/COD loading; however, the increase is in the form of simple sugars and related organic acids. These materials are much easier to digest than chlorinated phenolic compounds created in conventional bleaching. Since ClO2 usage is reduced, the effluent from the bleach plant has a lower toxicity. One should remember that by removing oxidant (i.e. ClO2), by definition, we will naturally have a higher COD/BOD content in the effluent.

(1) HOEKSTRA, PHILLIP – “Next Generation Technology for Enhancing Pulp Bleaching” – TAPPI PEERS 2016

Paper 360

Paper 360