You’re Not Too Busy—You’re Just Distracted

Picture this: You have established a plan for a new reliability initiative. The kickoff meetings have been held; the buzzwords are flying around. But on the plant floor? Crickets. Your reliability improvement project is slipping through the cracks. Why does this happen? It is easy to lose sight of the bigger picture in favor of tasks that can be dealt with right now.

IDCON recently participated in a preventive maintenance (PM) project at a paper mill in New York. Our responsibility was to lead the documentation of PM activities. Our first recommendation was to review the processes in the mill and then assign experienced maintenance people to do inspections right away (instead of beginning with documentation rounds). Why? Simple. If inspections start on Day One, we get quicker results than waiting for the documentation process.

This recommendation was almost instantly rejected because they wanted IDCON’s part of the project to focus only on documentation, not the processes, which we found highly unusual. Nevertheless, we focused on the documentation.

Round 1 was completed a few weeks into the project. At this point, inspections should have been done and tested on the floor, problems reported, and repairs executed.

Unfortunately, the decision makers at the paper mill continued to insist that the processes were not very important at this stage. “It’ll be fine,” they said, and instructed the team to learn how the inspections were supposed to be entered into SAP. IDCON’s stance was to let the team continue to use an Excel format until they were tested and implemented. You can probably guess what happened next.

The team focused only on getting the data into SAP. Nine months later, all PM is documented, but not a single inspection or repair job had been done. They had, however, hired several specialists to get the PMs into SAP. In other words, consultants have been on site, nearly a whole year’s worth of work has gone by, and there was zero to show for it.

FOLLOW UP IS KEY

As a maintenance leader it’s easy to lose focus and miss the importance of following up to make sure that results are being achieved and goals are being reached. Maybe you, like many others, have a myriad of urgent improvement projects on your to-do list right now. If so, you will likely need to:

- Improve planning, particularly daily and weekly planning.

- Improve the spare parts database.

- Improve daily scheduling of maintenance personnel.

- Polish PM inspections (documentation and implementation).

- Train personnel in the latest technical developments (especially instrumentation).

- Organize the storeroom.

- Work with design/construction so new equipment is maintenance-friendly and reliable.

Those are just some examples of improvements that can be made. These improvements will take place at the same time as regularly scheduled tasks and work. With all of this on top of the 4-6 hours of meetings in a day, it is no surprise that maintenance leaders can lose focus on the bigger goals and become distracted by tasks that will not produce the needed results and improvements in the end.

When it comes down to it, there are only two things that can provide reliability and maintenance improvement. Everything we do should focus on these goals:

- Preventing failures (prolonging the lifespan of equipment); and

- Faster, safer, and higher quality repairs.

Integrating these goals into the maintenance improvement plan is vital—executing them successfully gets results. Your actions must support these two goals to get direct results.

For example, documenting a mechanical inspection in the Computerized Maintenance Management System (CMMS) is important, but that documentation produces no results unless the inspection is done correctly. After a well-performed inspection, crew members report problems and failures. Then, repairs are planned and scheduled and executed. The follow-up plan for after a repair is completed should include steps to enable quick, safe, high-quality repairs to reach the end goal.

If we compare simply documenting inspections in the CMMS to tasks that actively improve equipment operations, such as aligning shafts well or making sure all lubrications are done with clean oil, it becomes clear that all these activities add to the lifespan of our equipment and yield immediate results.

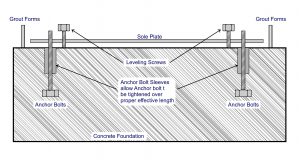

Some tasks are linked together like a chain, especially the activities that lead us to #2: faster, better, and more reliable repair. To work quickly and efficiently, these conditions must be in place: good scheduling and clear, prioritized planning and quality inspections. The figure here shows “The Chain.”

THE CHAIN THAT MUST NOT BE BROKEN

Improvements must lead to more efficient repair or preventing failures (preferably both). It is common to work on several improvements that are isolated from each other and neglect to address preventing a failure or making sure the repair is quick, safe, and well-executed. This is why sometimes we end up with zero results. We forget that project plans, leadership, meetings, maintenance systems, inspections, scheduling, and planning are completely useless if we don’t have personnel that can (or want to) repair or prevent the failures.

In the end, initiatives must result in prevented failures and repairs that are fast, safe, and high quality. As a maintenance leader, you need to communicate goals clearly, assign roles and responsibilities, offer practical support during implementation, and follow up on the improvement projects all the way until they actually happen on the floor.

Otherwise, you are just wasting time and money.