Process Intensification Using Membrane Separations

In manufacturing, separation processes driven by industrial heat (evaporators and distillation columns) account for 50 percent of energy consumption1 and, combined with high capital costs for new equipment, contribute up to 70 percent of the cost of producing a raw material or chemical, depending on the sector2. Commodity producers are also typically unwilling and/or unable to support green premiums3 to reduce energy consumption where such objectives are of political or strategic importance.

Via Separations, Watertown, MA, has delivered a product that improves the financial performance of a manufacturing facility. With Via, mills see average chemical savings of US$17/ton—complementing energy savings in regions with low fuel costs.

Via augments and replaces existing evaporator or distillation column infrastructure, providing both energy efficiency and electrification. By offering chemical savings, equipment stability improvements, production increases, and up to 90 percent energy savings, sites benefit from process intensification that aligns with financial objectives.

In 2024, Via delivered its first-of-a-kind (FOAK) commercial project to the pulp and paper industry, providing washing and production benefits to International Paper’s Grande Prairie facility in Alberta, Canada. Grande Prairie produces 380,000 air dry tons (ADT) of Northern Bleached Softwood Kraft (NBSK) pulp per year and directly employs 400 people. NBSK is primarily used in tissue and towel manufacturing. The FOAK Via system processes more than 20 percent of the mill’s black liquor, a valuable byproduct of the manufacturing process that is leveraged for re-use in manufacturing.

Informed by four separate pilots with Green Bay Packaging, Ahlstrom, and Graphic Packaging International, Via’s construction of the first commercial facility was completed in 10 months. The system—consisting of more than 600 membrane modules—was integrated into the mill with no downtime, has now surpassed 2,500 hours of operation, and encountered a 0 percent yield loss in the 100 million times scale up of the novel membrane technology. This system represents the largest implementation of membrane technology in industrial environments outside of the food and beverage and water purification/treatment sectors.

VALUE DRIVERS

The value drivers for mechanical separation enable up to a 5-10 percent increase in corporate EBIDTA when implemented across a pulp and paper manufacturer’s portfolio. Below, we share results quantified from data gathered during the first six months of operation at scale. This data reflects actual observed performance from the Via system; however, we have generalized the economic numbers based on industry averages. This article does not make any statements or insights about International Paper’s operations at Grande Prairie or generally.

Via Separations integrates into existing pulp manufacturing facilities between the washers and the evaporators, increasing the concentration solids of the black liquor and reducing the subsequent steam demand for evaporation, the chemical demand for the washers, and increasing the stability and production of the evaporators. In the case of Grande Prairie, Via processes a slip stream, but can also integrate into the full stream.

SEPARATING OUT SAVINGS

We can separate savings into different categories by type. We can also illustrate how each type of savings can be applied within the mill.

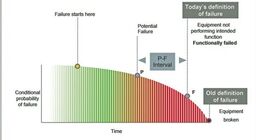

Energy Savings: Via delivers a 76 percent reduction in energy consumption compared to the incumbent evaporators. This amount already nets any reductions in power generation associated with reduced steam load. Energy consumption is measured as a specific energy per gallon of clean water removed (kWh/gal) including auxiliary systems and is compared to the thermal energy required to operate the evaporators. This dramatic energy reduction is possible because Via eliminates the need to drive a phase change in the fluid using heat. Via Separations’ membrane system uses electricity as the driving force (pressure) at a significantly reduced load than the thermal alternative.

The North American evaporator fleet is primarily composed of evaporators nearing end of life (median age 44 years) with a typical steam economy of 4.25 pounds (lbs) of water evaporated per lb of steam supplied4. Grande Prairie installed a new set of evaporators in 20115, so they are more energy efficient than the average North American evaporator; yet Via still demonstrated greater than 70 percent energy savings per gallon of clean water produced.

The Gen 2 implementation of Via’s membrane technology will further reduce system energy consumption by delivering throughput increases in the graphene oxide membranes. It will represent a 90 percent reduction in total energy consumption relative to evaporation.

Chemical Savings: An alternative way to leverage the operational benefits of membrane performance is to maintain the evaporator load but increase the amount of water used in pulp washing to reduce chemical consumption. Mills can use the additional water removal capacity from the membrane system to optimize the washing process. This reduces the energy per unit of water removed, while the amount of water is increased so that the total energy consumption remains relatively unchanged. At 2024 natural gas prices, this often offers a more attractive cost benefit to US mills.

The impact of this effect can be quantified by analyzing the optimum amount of water the mill should use to clean the pulp. This is represented by the net amount of water per ton of pulp added during washing, defined as the dilution factor. Increasing the dilution factor increases the required amount of water removal by a Via system or an evaporator set, while reducing the dilution factor increases the chemical costs to the mill for bleaching and makeup. The minimum costs associated with these steps thus defines the optimum dilution factor for mill operation.

Using the method published by Rivera et al.6 and updated to reflect typical energy prices for delivered gas and electricity to a US pulp mill (US$6.50/MMBTU and $45/MWh, respectively), we can calculate the impact of the measured performance of the Via system on washing economics.

The specific energy consumption for the FOAK at full capacity shifts the ideal dilution factor from 3 to 4 in a bleached mill (such as Grande Prairie) and 2 to 2.5 in an unbleached mill in this analysis. This generates savings of US$7.60 and US$6.30 per oven dry ton (ODT) of pulp, respectively. Implementation of Gen 2 systems pushes the anticipated savings for bleached and unbleached mills to US$18.50 and US$15.20 per ton, respectively, or US$13.1 million and US$10.7 million annually for a 2,000 ton/day mill at full scale. Gen 2 will offer further financial benefits, as illustrated in Figure 1. Via first published the basis for this analysis in TAPPI Journal in 2021. It has been updated here to reflect observed data. All dollar values are expressed in USD.

Evaporator Stability: Facility upsets and associated downtime often result in low solids flow entering the evaporator, which translates into instabilities and lost production. Though these may occur only a couple of times per year, they can represent a substantial amount of lost revenue with negative implications for facility margins. Inherent in the membrane system design is increased output during low solids events; the permeate (clean water) output at low solids is demonstrably higher than at high solids, delivering water removal when the facility needs it the most. With observed data summarized in Figure 2, the mill can translate the 93 percent boost in membrane production into accelerating the facility startup or recovery from an upset.

Production Debottlenecking: When a facility is seeking to produce additional tons of product—whether below or above nameplate capacity—water removal can be partially or fully leveraged for pulp production to drive revenue increases. Table 1 illustrates the marginal net revenue uplift for allocating permeate production to debottlenecking. For this analysis, we used a marginal value of US$250/ton to predict the approximate net revenue uplift.

Decarbonization: In regions with carbon pricing, a system the size of Via’s Grande Prairie installation avoids one ton of fossil fuel CO2 every 80 minutes, or 6,500 metric tpy. To date, assuming a biogenic or renewable source of electricity and full turndown of the evaporators, the project has displaced more than 600 tons of CO2, equivalent to 1.6 billion miles driven by gas powered vehicles7.

System Performance: Via’s black liquor concentration system is successfully meeting specific intermediate key performance indicators. Two of these—throughput and quality—are illustrated here.

Throughput: System performance is a culmination of more than a dozen membrane parameters, but one of the most significant drivers of capital and operating cost is throughput. Figure 3 illustrates expected and actual performance of membrane throughput for the 540 graphene oxide membranes representing over eight miles of material, normalized for confidentiality. The fluctuations in throughput through the first two months of operation represent system tuning and optimization, further variation is a result of fluctuations in feed solids. Across the entirety of the range average throughput was 37 percent higher than the initial design target.

Quality: The quality of the separated, clean water (permeate) is critical for its reuse in the mill’s process. Via has ensured the system can automatically respond (divert) should the quality of the permeate exceed design specification. Figure 4 shows the raw data for conductivity, which is used to measure the quality of the output. The shaded white regions are due to errors with the instrumentation. Minor excursions past the threshold are also evident, quickly returning to within specification automatically without affecting mill operations.

THE FIRST OF MANY OF A KIND

In September 2024, joined by representatives from International Paper and Natural Resources Canada, Via hosted a ribbon cutting in Grande Prairie. Via has three new products under development in adjacent sectors, and an inbound pipeline in pulp and paper, chemicals, and fuels. The industrial sector’s demand for process intensification will drive the company’s climate impact.

Achieving scale is critical for the growth of all climate technology businesses. The “burden of proof” in the industrial sector is particularly high. Frequently referred to as the “Climate Valley of Death,” scaling challenges include financing, transition of company focus, and customer offtakes.

For the Grande Prairie project, Via successfully productized a revolutionary technology developed in an academic lab in seven years with support from venture capital investors like Engine Ventures, NGP, Safar Partners, and Prime Impact Fund; industry partners such as the Biorenewable Development Consortium (BDC); accelerators such as Greentown Labs; and government programs including the US Department of Energy ARPA-E (DOE), MassCEC Catalyst, NSF Seed Fund, and Natural Resources Canada IFIT (NRCan).

There is more to come. Via is tackling the 700+ million metric ton (MMT) annual emission reduction opportunity across industrial manufacturing while lowering the cost of producing pulp by US$17/ton from chemical savings alone.