Lubricants: Unsung Heroes of Sustainability

In an era when environmental consciousness is paramount, the lubricants industry is emerging as an unexpected champion of sustainability. Contrary to popular belief, lubricants can indeed be “green,” offering significant environmental benefits while enhancing equipment performance and efficiency.

A HOLISTIC APPROACH

While traditional definitions of environmentally friendly lubricants focus on biodegradability, low toxicity, and non-bioaccumulation, a more comprehensive view reveals multiple facets of sustainability. Properly formulated lubricants contribute to energy conservation by reducing friction, which leads to decreased energy consumption and extended equipment life. High-performance lubricants can be formulated to last longer, promoting resource efficiency by reducing waste and conserving resources.

Advancements in technology have enabled the production of stable lubricants from renewable vegetable, animal, and algae sources, expanding the options for sustainable lubricant bases. Additionally, modern re-refining processes can transform used lubricants into high-quality base oils, creating a “closed loop” system that supports recycling and reuse initiatives.

BEYOND BIODEGRADABILITY

While biodegradability remains a crucial aspect of green lubricants, industry professionals should consider additional factors to fully assess environmental impact. “Ecotoxicity” measurements help determine a lubricant’s potential harm to environmental organisms, providing valuable insight into its overall ecological footprint. Bioaccumulation assessments evaluate the tendency of a substance to accumulate in living organisms over time, which is critical for understanding long-term environmental effects.

Furthermore, embracing cradle-to-cradle design principles encourages the development of circular product lifecycles through intelligent design and manufacturing processes, promoting sustainability throughout the lubricant’s entire lifespan.

PAIR LUBRICANTS WITH PREVENTIVE MAINTENANCE AND STAFF TRAINING

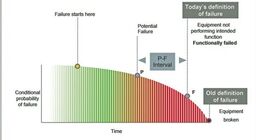

Predictive or preventive maintenance also plays a key role in optimizing lubrication efficiency. Mills can develop strategies to predict when a piece of equipment is expected to fail, then schedule and plan maintenance on the asset to avoid that failure. Many industries are trending toward scheduling oil changes with predictive condition-based methods versus older time-based methods.

A thorough evaluation of a mill’s lubrication program can help. For example, Lubrication Engineers offers its Xpert Lubrication Benchmark Audit, a one-day walkthrough that ranks a facility’s lubrication program compared to industry standards and best practices. Audit categories include lubrication best practices, asset and lubricant identification, storage and handling, contamination control, filtration, training, skill development and certifications, and safety and accessibility.

Also available is the Xpert Equipment Reliability Assessment, in which every rotating piece of equipment is evaluated with the goal of building reliability around critical assets. After review, the team prepares an agenda with a prioritized plan of action to move the facility’s needle up to best practices and expected ROI.

BUSINESS CASE FOR GREEN LUBRICANTS

Adopting sustainable lubricant practices isn’t just environmentally responsible—it’s economically sound. A well-implemented lubrication program can significantly enhance equipment uptime and efficiency, leading to improved equipment reliability and reduced operational costs. High-quality lubricants capable of operating for longer periods contribute to extended drain intervals, reducing maintenance costs and resource consumption.

Moreover, lubricants that effectively reduce friction can lead to measurable decreases in power consumption, translating to significant energy savings and cost reductions for businesses. This alignment of environmental and economic benefits makes a compelling case for the adoption of green lubricant practices across industries.

IMPLEMENTING A GREEN LUBRICATION STRATEGY

To maximize the sustainability benefits of lubricants, businesses should consider implementing these lubrication reliability best practices:

- Employee training

- Proper filtration and contamination control measures

- Oil analysis program to optimize drain intervals

- Automatic lubrication systems for improved efficiency

The lubricants industry stands at the intersection of environmental stewardship and operational excellence. By adopting a holistic view of green lubricants—one that considers their entire lifecycle and performance benefits—businesses can simultaneously reduce their environmental impact and improve their bottom line.

As the industry continues to innovate, partnering with knowledgeable lubricant suppliers will be crucial. Lubrication Engineers, Inc., with its expertise in formulating high-performance, environmentally considerate lubricants, is well-positioned to assist businesses in implementing effective green lubrication strategies. A commitment to sustainability, coupled with advanced product offerings, makes them an ideal partner for companies hoping to enhance their environmental profile while improving operational efficiency.

With the right approach and support, lubricants can indeed be green, contributing to a more sustainable and efficient industrial future. By choosing environmentally responsible lubricants and implementing best practices in lubrication management, businesses can reduce their environmental footprint while reaping the economic benefits of improved equipment performance and longevity.