Energy Efficiency Requires a Comprehensive Approach

Pulp and paper manufacturing continues to be a cornerstone of the global industry, yet it remains one of the most energy-intensive sectors, second only to chemicals. As author Dick Reese notes on page 14, energy expenses can account for 10-40 percent of total manufacturing costs. These high demands underscore the crucial need for energy efficiency to maintain profitability.

Technological advancements, process improvements, and reductions in water usage have collectively driven a measurable decline in overall energy consumption over the past decade. However, with increasing regulatory pressures and the growing emphasis on sustainability, pulp and paper manufacturers must continue seeking innovative solutions to reduce energy use and costs .

HARNESS WASTE WITH BIOREACTORS

Organic waste streams present both a challenge and an opportunity for pulp and paper mills. Instead of viewing waste as a disposal issue, mills can leverage it as a valuable resource for energy generation. One innovative solution involves using anaerobic bioreactors to convert organic-rich waste streams into methane. Bioreactors process waste through anaerobic digestion into biogas, which can be used as fuel for boilers. This reduces reliance on traditional energy sources and lowers wastewater’s biological oxygen demand, simplifying treatment processes.

S&B, an integrated engineering firm based in Houston, TX, has successfully delivered bioreactor projects in this segment. By converting waste streams into viable fuel sources, these projects enhance energy efficiency and contribute to improved environmental sustainability, showcasing how waste can be transformed into a key asset for mills.

At its Nymolla Mill in Sweden, Stora Enso has transformed waste management into an energy opportunity. The company’s biogas plant harnesses the potential of wastewater from mill operations and converts it into biogas. The facility converts wastewater into biogas, upgrades it to natural gas quality, and feeds it into the Swedish gas grid. This clever reuse of waste reduces the mill’s carbon emissions and adds a significant renewable energy source to Sweden’s power mix. The project shows how industrial byproducts can become a valuable resource.

INNOVATE WITH MEMBRANE TECHNOLOGIES

Emerging technologies revolutionize the way pulp and paper mills approach energy efficiency. Reverse osmosis (RO) and other membrane technologies gain attention because they can optimize energy use during pulping.

One of the most energy-intensive steps in pulp production remains the evaporation of black liquor, a byproduct containing spen cooking chemicals and organic materials. RO technology can concentrate black liquor before evaporation, significantly reducing the required steam.

Although full-scale implementation of RO systems in pulp mills is still evolving, research and pilot projects suggest the potential for dramatic energy savings.

OPTIMIZE STEAM SYSTEMS

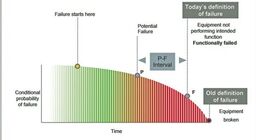

Steam systems can offer one of the most effective ways to enhance energy efficiency in paper mills. Conducting thorough audits and assessments of steam systems allows mills to identify areas where they can reduce steam usage, which can translate into substantial energy savings.

Technologies such as thermal compressors provide an effective solution through improved utilization of low-pressure steam. Thermal compressors capture vented low-pressure steam and recompress it to a higher pressure, increasing overall efficiency and reducing the need for high-pressure steam throughout the mill. This approach can help maximize the use of existing resources and cut energy consumption.

REDUCE WATER USAGE

Water is another essential resource in pulp and paper manufacturing. Mills often consume 10 to 50 million gallons of water daily, much of which is recycled. However, regulatory mandates increasingly require mills to reduce their water usage by 10-15 percent.

Conducting water audits is a practical first step in identifying opportunities for improvement. These audits analyze the entire water lifecycle within the mill, pinpointing areas where recycling or reuse can be maximized. For instance, wastewater from one process can often be treated and reused in another to reduce the overall demand for fresh water.

Optimizing water usage can also lead to significant operational benefits such as lower energy costs associated with heating and treating water. These improvements also enhance the mill’s sustainability profile, making it more attractive to eco-conscious customers and investors .

A COMPREHENSIVE APPROACH

Energy efficiency in the pulp and paper industry requires more than isolated fixes. The most successful strategies are holistic: integrating waste management, water use optimization, and advanced technologies like membrane systems and thermal compressors.

Engineering, procurement, and construction (EPC) experts play a critical role in helping mills navigate these complexities. EPC firms can design and implement tailored solutions that address operational and environmental challenges by conducting thorough assessments and collaborating closely with mill operators.

For example, in a recent multi-year project, S&B conducted comprehensive evaluations of more than 30 mills, using front-end loading processes to identify and prioritize upgrades. The team developed detailed designs that integrated production efficiency improvements, modernized machine controls, and expanded roll size capabilities. By combining advanced system upgrades with targeted steam audits and vendor-specific solutions, the project achieved significant gains in energy efficiency while minimizing downtime.

Adopting a comprehensive strategy enables mills to maximize energy savings, reduce operating costs, and enhance long-term sustainability.

As the industry faces increasing regulatory pressures, rising energy costs, and a growing demand for sustainability, it is essential to embrace innovative technologies and comprehensive approaches. From harnessing waste through bioreactors to implementing cutting-edge membrane technologies, optimizing steam systems, and reducing water usage, mills can unlock significant operational improvements while contributing to a more sustainable future. These advancements reduce costs and environmental footprints and enhance resilience in a competitive market.