KIM “WILL” ROBINSON

Historically, the pulp and paper industry has risen to the challenge of solving issues with the skills available; yet these skills are not being updated and refreshed. An APS approach can re-establish the skills our workforce needs.

In the day and age of global improvements in consistency and quality across many manufacturing sectors, pulp and paper mills are still encountering processing problems too frequently. For the most part, papermakers have become adept at diagnosing and fixing problems, particularly when they are one-dimensional. These types of problems emerge out of a direct “cause-effect” framework. Their root-cause diagnosis is simple, straightforward, and often requires only repair or recalibration of some process component. Process problems starting, recognized, and having a measurable impact within a department are often the problems most quickly diagnosed and resolved.

For instance, when a paper break occurs between the third and fourth dryer sections, it is far easier for the machine tender to check the tightness of the draws and assign the draw setting as the core problem. For the papermaking crew, the problem started and stopped within the department. However, if a furnish change created the same paper break, it will be more difficult to assign an upstream cause. System-wide problems, such as those arising in the woodyard or some fiber make-down process, are much more difficult to solve.

A common but unhelpful habit is to define a problem as, in fact, the symptoms of the problem. For instance, low MD tensile in the final product is a “tensile problem” for the operations group, but it is not the real problem creating the issue, it is the effect. Naming the effect as the problem tends to restrict the focus on only the testing department or paper machine; whereas, the problem can have its origin further upstream, as in the example with paper breaks.

PROBLEM INVESTIGATION TEAM

Most mills have issues that resist straightforward, simple solutions. These problems are more complex and require a different level of thinking. It is necessary to employ a more disciplined approach to identify the core problem. Frequently, these process deviations are a “perfect storm” of process circumstances that come together to create a manufacturing problem. Multi-factor causes are the most difficult ones that a mill will encounter. Over time, if the problem persists, departmental staff members will try to solve them, yet without success.

When multiple attempts to solve these problems fail, the underlying factors remain and become embedded into “the way the mill operates.” These undiagnosed issues are present in each corner of a mill, yet are no longer in the “problem” category. If you ask the staff of a mill if they have any operational problems, the most common answer is “No, we’re fine.” But when you ask if they observe frequent “wet streaks,” non-uniform CD profiles, non-mechanical sheet breaks, etc. the answers usually confirm deeper, un-named process issues routinely undermining mill performance and stability (as well as employees’ job satisfaction.)

Mills unfamiliar with solving problems at this level should form one or more investigative teams at the facility. This team must have management’s support and authority to launch investigations, brainstorm, and test potential solutions. Unless that is done, we have a group of bright, capable, operators, engineers, and managers who are less prepared to analytically dig into issues at their mill.

MILL PROBLEM-SOLVING

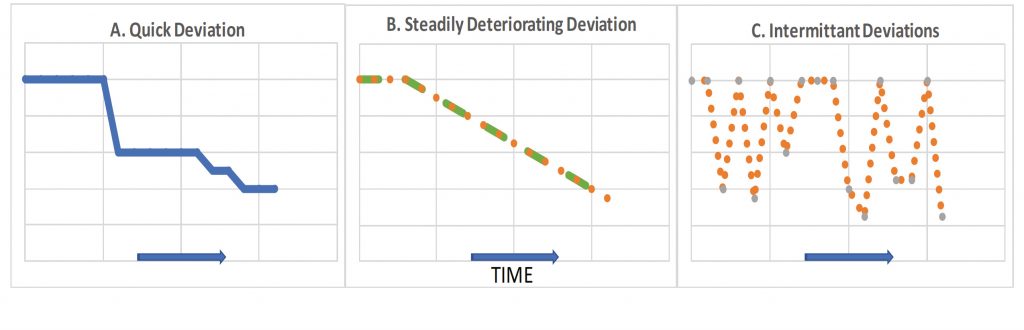

The first recognition of a new production problem shows up through an abnormal process or product quality deviation. Human nature tends to recognize bad (negative) deviations as undesirable, particularly when they impact quality or productivity. These deviations can first manifest themselves in end-product testing, process instability (e.g., paper breaks), or some other unanticipated process variation. Figure 1 illustrates several common types of process deviations: deviations that occur rapidly and do not recover (1A), steadily deteriorate over time (1B), or intermittently deviate from the norm or desired state (1C).

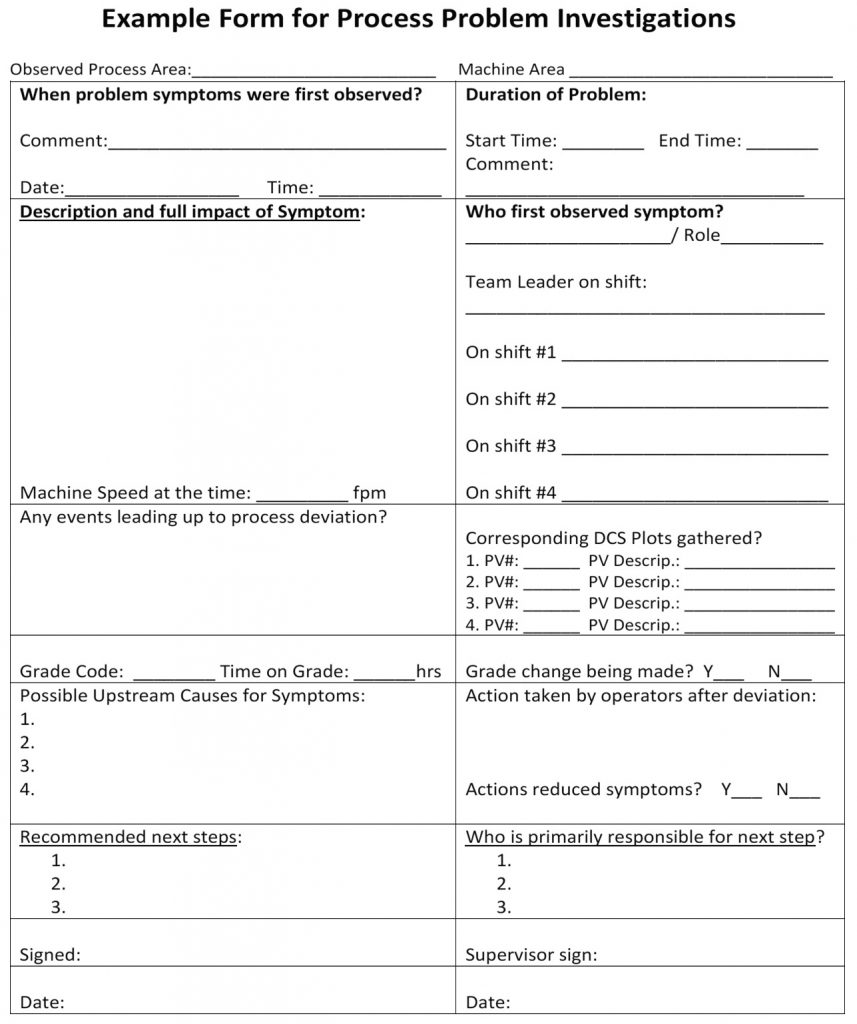

Most mill production problems result from an up-stream cause(s). When an operator or tester observes a meaningful and undesirable deviation from expectations, an organized “first-responder” effort is necessary to capture the process circumstances surrounding the problems. Figure 2 shows an example form that can help in the initial data collection effort.

ANALYTICAL PROBLEM SOLVING

For harder-to-uncover root problems, valuable existing methods can provide a much-needed systematic and disciplined approach to problem-solving. Several formalized and popular analytical problem solving (APS) approaches available to the mill investigator include those provided by Princeton Associates (W. Altier)1, Kepner-Tregoe2, Blue Dragon3, and others4.

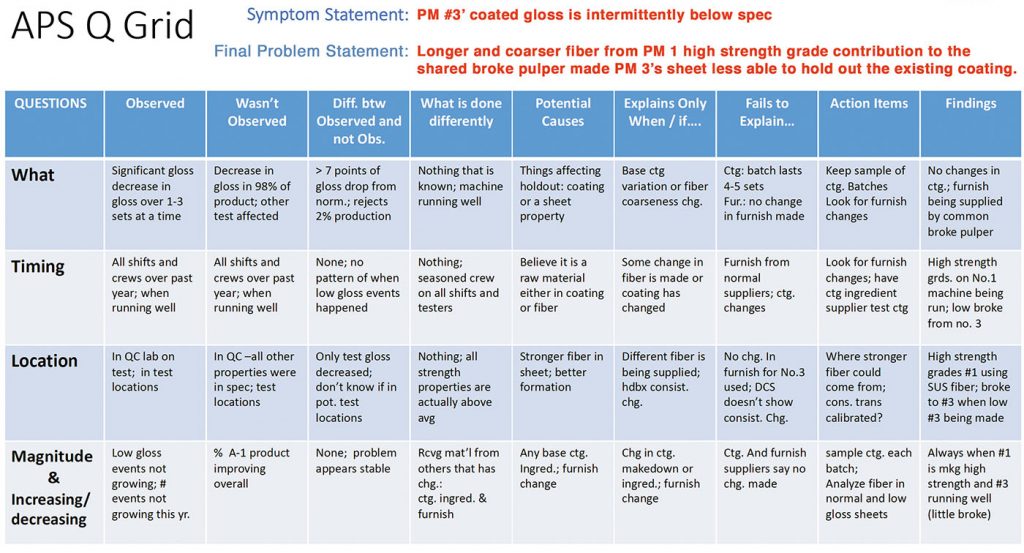

Several days of workshop training can effectively prepare team members to use these tools to gain confidence in the APS process. These APS methodologies have, at their core, ways to flush out and clarify what is known (and not known) about the up-stream processes impact on a downstream deviation. Table 1 gives an example of a form the problem solver can use to practice applying the APS framework—using a fictitious problem.

Table 1 (on next page) further helps the investigation team narrow its focus. By this time, the APS questions asked and answered begin to eliminate assumptions that are detrimental to the clear and open thinking that APS requires.

KNOWING WHAT YOU DON’T KNOW

The APS process will initially result in creating more questions than answers. The analytical problem solver’s thinking expands by not knowing some dimension of the problem. The access to additional data may be simple or difficult. Watching an existing suspect PV and then downloading it from the data archive before, during, and after the “deviation” period may be all that is necessary. However, more difficult problems have, at their root cause, no “meter” on them in the process. For instance, a colloidal build-up in the white water, a change in chemistry at the wet end, non-uniformity of sizing, etc. creates the need to test another parameter consistent with the deviation presented in Table 1, “Action Items.” These surrogate measurements require some creativity. The question the team must ask is: “What also goes up or down with the thing we wish to study and how would we observe/measure it?”

The APS process will narrow the list of possible causes listed in Table 1. Each cause remaining after elimination of those that fail to consistently offer viable explanations become candidates for consideration.

How do you go about establishing the root cause? If the team can simply measure a PV directly that tracks a potential cause, it may only be necessary to study absolute values and/or variability in the data during the deviation period. You’ll need to determine what factors are contributing to these changes. Further upstream PV analysis usually hints as to the root cause.

If direct measurement of one of the team’s potential causes proves elusive, it may be necessary to “ping” the operation with increases or decreases of the process factor you believe is the root cause of the problem.

Finally, your team is in a good position to create an accurate problem statement. Understanding the problem, the team should then turn its efforts to creating sustainable solutions. Papermakers often know exactly a correct action to take once they have a defined a root problem.

BENEFITS TO THE WORKFORCE

While some organizations might relegate APS investigations to engineers or frontline supervisors, these techniques are richest when a team consisting of a vertical slice through the organization are invited to participate.

The first benefit is that all members of a trained APS team forever after “think differently” about events around them. While an appointed principal investigator might be assigned a given problem, all team members then participate in brainstorming potential causes, collecting “event” data, and listing process assumptions. Broadening these skills to a wider group at the mill is intentional, after initial APS team’s efforts yield successful outcomes.

Employees who actively participate in APS are more engaged and create more value for the organization, contributing to its success. Persistent problems are solved and the quality of life at the mill improves. Experts tell us that employee retention improves when engagement, personal development, and professional recognition are central to a company’s culture.

HABITS OF GREAT COMPANIES

Companies that embrace total quality and unending process improvement can solve problems when they arise with permanent fixes. These companies document the change in department SOPs and train current and future employees on all team insights and recommendations.

At all levels, pulp and paper industry leadership has accomplished remarkable safety improvements over the past 30 years. This has led to proactive implementation of improvements, documenting better process understanding parallel to the approach used in safety training of current and future personnel. Many layers of leadership support the safety investigation process fueled by support and commitment to rid the mill of all hazards. The APS approach lends itself to a similar framework and gives safety-conscious mills an advantage in scripting the APS into the safety investigation and resolution process.

APS is an effective way to eliminate problems so recurrence is highly unlikely. Leadership that supports and drives a rigorous problem investigation culture empowers its team to challenge long-held process assumptions and get to the root cause. The use of APS tools creates a disciplined approach and a better way of thinking about problems by creating a common mill language.

In this type of environment, historic problems no longer persist. Employees within the organization support one another to solve their day-to-day problems…for good.

Kim “Will” Robinson has a BS in paper engineering from SUNY, MS and Ph.D degrees from the Institute of Paper Chemistry, and an MBA from the University of Chicago. He has held leadership posts with International Paper, James River (Graphic Packaging), and Caraustar. For the past 10 years, his efforts have been focused on assisting mills in overcoming systemic operating difficulties. Reach him at [email protected].

References:

1. Altier, William J., The Thinking Manager’s Toolbox, Oxford University Press, 1999.

2. Kepner, Charles H. and Tregoe, Benjamin B., The New Rational Manager, Princeton Research Press, 1981.

3. De La Espriella, Rob and Bernhard, Charles D., www.dle-services.com, 2017.

4. American Society for Quality (ASQ), Toronto Section, Is – Is Not Tool, https://asqtoronto.org/resources/quality-tools/problem-solving-analysis-tools/, 2020.

.

Paper 360

Paper 360