Husum, Sweden, is a coastal town along the Gulf of Bothnia, across from Finland’s West Coast; it is also home to Metsä Board Husum, a leading European pulp and paperboard manufacturer. This modern mill produces bleached chemical pulp and paperboard and is one of Europe’s top manufacturers of folding box board for gift packaging and other high-end paperboard products. Jan Edlund is reliability engineer and head of preventive maintenance at Metsä Board Husum, and it is his job to ensure the machines continue running smoothly, with no unexpected interruptions.

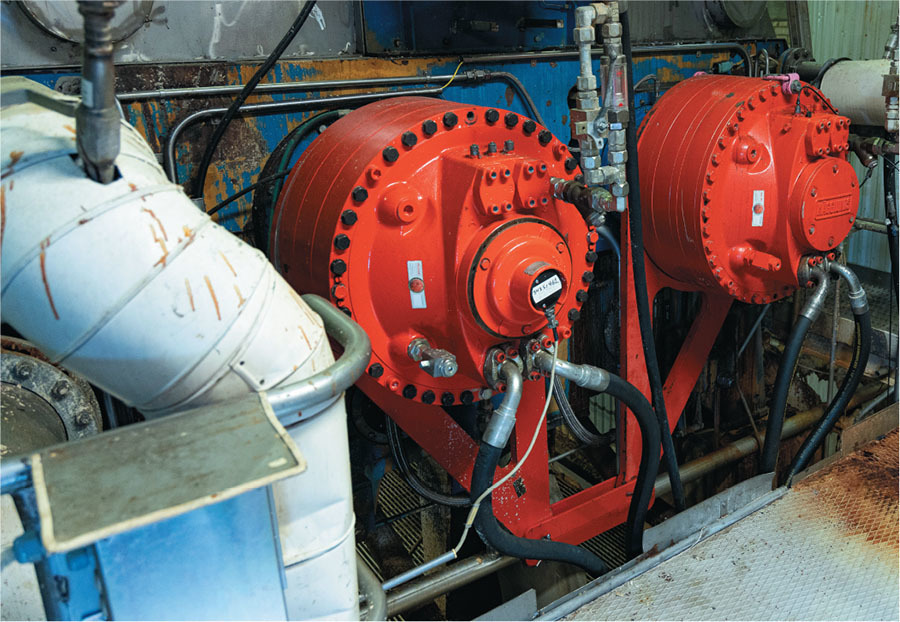

Hydraulic drives in place at Metsä Board Husum, Sweden.

“We’ve set up new routines for preventive maintenance,” Edlund says. “Many years ago we had 17 employees working on pump repairs. Thanks to preventive maintenance, we’ve been able to reduce that number to two. We find a fault, create a work order and carry out maintenance during scheduled shutdowns. We are naturally prepared to tackle problems, but despite having thousands of motors and pumps, the team is rarely called out.”

That picture is confirmed by Mattias Ahlqvist, a hydraulics technician. “Very little goes wrong. I started in 2007 and I’ve hardly ever seen a breakdown,” Ahlqvist says. One reason? Because high reliability is so important, hydraulic drive systems have increasingly become the company’s choice. “We now have 21 hydraulic motors in operation. We’ve switched from gearboxes to hydraulic motors in several locations,” Edlund reports.

“It’s important to have reliable suppliers when we need help,” says Edlund. “It’s also good to have a fresh pair of eyes to check out our machines.”

“It’s important to have reliable suppliers when we need help,” says Edlund. “It’s also good to have a fresh pair of eyes to check out our machines.”IDEAL APPLICATION FOR HYDRAULICS

Hydraulic motors can be installed almost anywhere in a pulp and paper mill. The Husum mill has no shortage of examples. The company chose Hägglunds hydraulic drives from Bosch Rexroth to install in class A applications—wherever production losses would quickly get expensive if a machine came to a stop. Examples include the cooking and washing stages, as well as conveyors and reactors.

A Hägglunds direct drive system comprises a hydraulic motor and a flexibly placed drive unit, overseen by a control and monitoring system. “For those of us who work in maintenance and production, this type of drive solution is a dream because of its low rpm and high torque. If you want reliability, hydraulic drives are the answer. It’s also relatively easy to replace a hydraulic motor, since no foundation is needed,” says Edlund.

The Husum mill’s relationship with Hägglunds drive solutions began in the mid-1970s, long before Hägglunds joined the Bosch Rexroth family. At that time, the mill was investing in new washing equipment for one of its pulp lines.

“We installed Hägglunds Viking hydraulic motors on the wash presses,” Edlund says. “In fact, one of the motors we installed in 1976 is still running today. This experience taught us the value of characteristics such as quality and reliability, and it led us to install the 20-plus drives we have at the mill today.”

WORKING AS A TEAM

Metsä Board Husum handles its own replacement of motors and pumps, but the company also takes in specialist advice from the Hägglunds team at Bosch Rexroth.

“It’s important to have reliable suppliers when we need help. This is especially true when it comes to replacement parts, which can otherwise have very long delivery times,” says Edlund. “It’s also good to have a fresh pair of eyes to check out our machines. Sometimes you overlook things you see every day, so you might miss a small leak. Regular cleaning helps to prolong the service life.”

Hägglunds offers all customers service agreements, and each contract is tailored to the individual customer. The Husum mill has a contract for regular servicing by Hägglunds specialists. Teamwork between the Metsä and Hägglunds service teams has extended the service life of the drives.

“The benefit of having a contract with Hägglunds is that we can contact them if anything unexpected happens at the mill and we need help,” says Hydraulics Technician Niklas Sjölund. “They are very accessible and show up quickly to help. Because we have worked closely with Hägglunds for such a long time, we also know what products they have and how quickly they deliver. This is especially important if we need parts urgently, as we know we can rely on them.”

Ahlqvist agrees. “They have a great service organization. On the few occasions there has been a fault they have solved it quickly, even complex problems. The standard of service and reliability is excellent. For example, when we once needed a back-up pump, we were able to borrow one from them.”

EARLY ADOPTER

Metsä Board Husum aims to lead the way in adopting new technology and likes to test new solutions at an early stage.

“Thanks to our interest in technical development, we’ve been able to try out new equipment from Hägglunds over the years,” says Edlund. “We tried out the very first Marathon motors, as well as the CB motors when they were developed. That helps us see future solutions, both for production and for maintaining our equipment. This can involve everything from AI and the development of maintenance products to new methods for manufacturing products.

“As a result, Metsä Board Husum was one of the first to install Hägglunds CMp—a maintenance tool that continuously monitors the condition of the hydraulic system.

“We are increasingly investing in this form of monitoring as AI solutions and remote monitoring are built into the machines,” says Sjölund. “For us, the benefit of CMp is that it lets us check all the parameters in real time from a computer. It also means that Hägglunds personnel can inform us if they see any odd behavior in the drives. Even though we monitor them ourselves, it’s good to have a second opinion. There are many Hägglunds installations that are similar, so they are very good at assessing condition.”

Contact , industry sector manager, Pulp & Paper, for Hägglunds, at [email protected]. Learn more about Metsä Board Husum at metsagroup.com.

Paper 360

Paper 360