Catch up with Tor's latest installment in the series "How to Document Cost-Effective Preventive Maintenance" here.

Read More »Tag Archives: preventive maintenance

Choosing a Maintenance Method

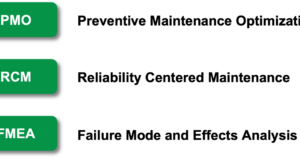

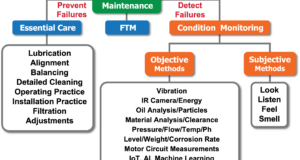

In terms of Maintenance Methods, there are three choices for existing equipment. They are Operate to Breakdown, Fixed Time Maintenance, and Condition Based Maintenance. Operate to Breakdown: The equipment is run until it breaks down. Fixed Time Maintenance: The replacement of parts or equipment on a fixed/scheduled frequency. Condition Based Maintenance: The problem is found and fixed at the time when it is discovered. It is a common assumption that Condition Based Maintenance is always the most cost effective. While this is commonly the case, it is not always true.

Read More »Equipment Doesn’t Break Down, Components Do!

What is a component? IDCON uses the word “component” to describe an item that is highly repetitive for preventive maintenance purposes. For example, the AC motor on the infeed hydraulic unit is composed of several components or machine elements. The infeed hydraulic unit is a highly repetitive unit often found in paper mills, refineries, mines, etc. AC motors are a component that is reoccurring as well.

Read More »How to Document Cost-Effective Maintenance Tasks Part 3: Process for Documenting Preventive Maintenance Tasks

Part 3 in this series focuses on Preventive Maintenance documentation processes. In order to document a cost-effective preventive maintenance system, there must be a clear and established process in place for how to document PMs. It is not enough to rely on vendor information and personal experience alone.

Read More »How to Document Cost-Effective Maintenance Tasks Part 2: The Productivity Circle

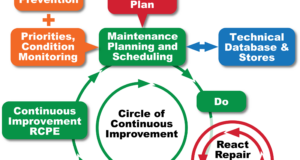

Part 2 in this series covers how Preventive Maintenance fits into the overall Reliability and Maintenance cycle. Figure 1 shows IDCON’s Productivity Circle which is used to demonstrate the overall partnership between Operations and Maintenance.

Read More »How to Document Cost-Effective Maintenance Tasks Part 1: Preventive Maintenance Definition

IDCON’s latest series will detail the correct way to document cost-effective maintenance tasks. The first thing to do is go back to the basics. Part 1 will cover the background and theory of how to achieve the correct tasks and documenting Preventive Maintenance tasks.

Read More »What NOT to Do as a Maintenance Planner

by Torbjörn Idhammar Every organization needs to provide planners with a clear job description. That description may differ among companies due to the size of the organization. Some companies combine the roles of planner and supervisor. Others have dedicated planners for shutdowns/turnarounds. Many have staff members with the title of “planner” who do not do any actual planning. So, how ...

Read More »Is Your Preventive Maintenance Program Right for Your Plant?

Regardless of where the opportunities for improvement exist, it is very common that we begin working on improvements in the area of planning and scheduling (P&S).

Read More » Paper 360

Paper 360