Whether on the job site or at its tech-enabled Construction Innovation Lab, Miron uses VPI to bring project teams together. JAN BOTTIGLIERI The local multiplex is not the only place where papermakers can enjoy the immersive experience of modern 3D technology. They may also head to the Neenah, WI, headquarters of Miron Construction Co., Inc. There, in a tech-enabled facility ...

Read More »Techlink

TJ SUMMARIES

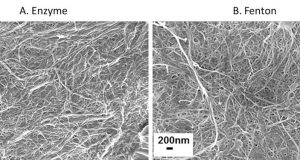

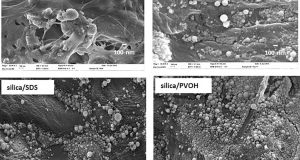

THE PAPERS SUMMARIZED HERE are from the June 2016 issue of TAPPI Journal featuring special nanotechnology content, along with the July 2016 issue featuring special content from the 2015 PEERS Conference. TAPPI Journal is an online publication of relevant and timely peer-reviewed research delivered via email and free to all TAPPI members. To receive TAPPI Journal, join TAPPI at www.tappi.org. ...

Read More »Klingele Papierwerke Saves Money, ‘Foils’ Stickies

KENTARO TAJIRI AND THOMAS WISCHEROPP For years, Klingele Papierwerke in Weener, Germany, had suffered from less than ideal conditions on its first top dryer fabric, including short fabric life and serious sheet moisture profile variation. The mill had used “spot cleaners” and off-line washes, yet was not satisfied with running and maintenance costs and the detrimental effect of stickies on ...

Read More »Innovative Direct Drive in a Turnkey-rebuild Project

RAMAZAN ATAMAN At Mondi’s Dynäs mill in Väja, Sweden, mechanical problems and high maintenance costs proved that the drive system on PM 6 needed a rebuild. Mondi Dynäs PM 6 produces sack kraft paper with basis weight ranges from 50–160 g/m2 and a web width of 6,500 mm. In 2014, the machine speed was 775 m/min. Before the rebuild, the ...

Read More »TJ Summaries

The papers summarized here are from the August 2016 and September 2016 issues of TAPPI Journal. TAPPI Journal is an online publication of relevant and timely peer-reviewed research delivered via email and free to all TAPPI members. To receive TAPPI Journal, join TAPPI at www.tappi.org. AUGUST FIBER SUPPLY Examination of the potential to reduce water application rates for hardwood pulp ...

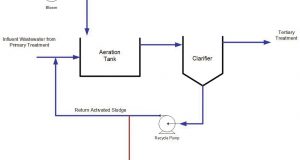

Read More »Best Practices for Wastewater Treatment and Management

VIPIN SUMANI AND THOMAS S. SEGULJIC The pulp and paper industry is one of the heaviest users of water in the US, using almost 15,000 gallons of water per ton of finished product. With water used in nearly every step of the production process, the large volumes of wastewater and residual sludge waste present treatment, discharge and disposal issues. Coupled ...

Read More »The Next-Generation QCS

New scanning sensors, soft sensors, open-ended multivariable control, and the first steps to integration with web inspection are expanding the definition of quality control. MARK WILLIAMSON It’s been almost 50 years since the first computer-based paper machine quality control systems hit the market. Over the intervening years, a lot has happened to advance the scope and effectiveness of the measurement ...

Read More »TJ Summaries

The papers summarized here are from the June 2017 and July 2017 issues of TAPPI Journal. TAPPI Journal is an online publication of relevant and timely peer-reviewed research delivered via email and free to all TAPPI members. To receive TAPPI Journal, join TAPPI at www.tappi.org. JUNE BLEACHING Improving the efficiency of hydrogen peroxide bleaching of chemimechanical pulp by continuous replenishment ...

Read More »Making Good Bacteria Even Better: Bioaugmentation in Pulp and Paper Wastewater Treatment

JENNIFER BAILEY As the world’s need for clean, sustainable water sources continues to increase, so does the need for industrial operations to reduce freshwater intake and to efficiently treat wastewater before it is released back into the environment. Pulp and paper manufacturers, as participants in a particularly water-intensive industry, have a special responsibility to control and optimize water use throughout ...

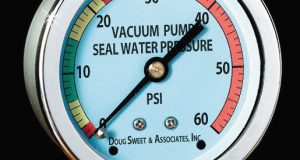

Read More »Papermaking Best Practices With Vacuum-Dewatering Systems: Part 1

DOUG SWEET, P.E. Vacuum systems are essential for papermaking. They contribute to sheet formation and dewatering, press performance, felt conditioning, and general machine efficiency. The vacuum system includes several sub-systems for vacuum control, air/water separation, and vacuum pump seal water management. Generally, paper machines operate with little attention required of the vacuum processes. Yet these systems tend to evolve into ...

Read More » Paper 360

Paper 360