“What was once a brown box is now a marketing platform, a key component of the omni-channel brand experience.” —Robert Seay, vice president, digital print strategy for Georgia-Pacific. (Photo: Georgia-Pacific)

“What was once a brown box is now a marketing platform, a key component of the omni-channel brand experience.” —Robert Seay, vice president, digital print strategy for Georgia-Pacific. (Photo: Georgia-Pacific)

New digital inks and printing processes are changing the way corrugated boxes look and function. No longer just a “plain brown box,” corrugated packaging can do more than ever in terms of altering consumer perception, conveying product information, and serving new markets. Vendors of digital printing machinery and inks have helped make that happen with products and services that will help define the future for their customers.

Paper360° reached out to three corrugated industry vendors doing exciting things in the digital printing arena. The future they see ahead for corrugated manufacturers is as bright … as the digital images on the side of a corrugated box!

HOW WE GOT HERE

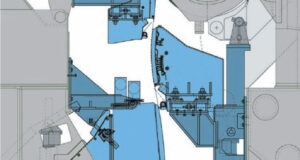

Corrugated is a dynamic industry with constantly developing technology; but when it comes to digital printing, our pros were able to point out the most impactful development. “The single biggest advancement has been the movement from slow, multi-pass printers, into single-pass printing. This movement to a faster, more productive method has fueled other digital technology suppliers to put a tremendous focus on corrugated packaging and displays,” says Lloyd Kent, vice president, sales and operations for Kento North America. “This includes various software that runs, oversees/manages, and enhances digital print. Also, many offset and flexo ink manufacturers have jumped into the digital arena, which means greater competition and ultimately lower consumable costs.”

Single-pass printing is the gateway to faster production times, more design flexibility, and a streamlined supply chain, says Robert Seay, vice president, digital print strategy for Georgia-Pacific. “By eliminating the need for print plates, designs can be turned around faster, leading to quicker change request completion and, ultimately, faster sign-off on the final product,” says Seay. “Roll presses offer large volume as well as lower | DIGITAL PRINTING minimum quantities with full-color, photo quality graphics. The ability to order what is needed, when it’s needed helps mitigate supply chain challenges and allows companies to accommodate changing demand without the risk of excess inventory.”

This change has given manufacturers many more capabilities than they had only 10 years ago—and many more options. “The number and types of printers has changed greatly. Today there are numerous manufacturers selling single pass printers for sheet printing, and roll-to-roll printers for webs. Resolutions have improved significantly and litho quality print is capable from many printers. Print speeds have more than doubled, and in some cases, tripled in the last 10 years,” comments Jim Wegemer, director of national accounts for INX International Ink Co.

His colleague Jim Lambert, vice president of INX’s Digital Division, notes that ink technologies have needed to keep pace with printer advances. “This has meant faster drying or curing, the ability to jet through smaller nozzle sizes, and the ability to have better rub resistance and flexibility. All of this has been accomplished while economics have improved, providing better value to printers and end users.

“Workflow, stackers, feeders, die cutting, and finishing have needed to improve and keep pace with the demands and expectations of digital print,” Lambert says. “The future for digital will keep pushing the envelope: faster speeds, the ability to print on a broader range of substrates, more print units to allow for more specialty work, and more digital hybrid solutions that combine the best of conventional and digital print together. Inline die cutting solutions might be a possibility.”

Kento’s Lloyd Kent expects a future that will include methods to reduce overall digital print costs. “Specifically, producers will be lowering ink and associated consumables costs using hybrid technology that uses flexo for large solids, and offering solutions like in-line die cutting—plus other technologies to enhance the print such as white ink, metallic ink, and various overprint varnish (OPV) options.”

NEW MARKETS AHEAD

For GP’s Robert Seay, the future means new markets. “Going forward, manufacturers will continue to address deficiencies in platform solutions that hold back expanded market penetration,” he says. “These areas include running costs, reliability, uptime, systems integration, solution life expectancy and total cost of ownership.

“As digital print solutions become more robust and efficient, they will more and more address gaps in the existing corrugated market where it makes sense. Examples include more digital sheets from sheet feeders or expanded substrates like uncoated brown and white applications. Digital print solution concepts incubated in corrugated can transition into other markets such as carton board, kraft paper, mailers, and more as digital print solutions mature,” says Seay.

“It’s important to note that digital assets open the door to new opportunities and make a huge difference in the productivity of all machines in a corrugated plant by allowing for each machine to be used for what it does best,” says Kent. “Many companies adding digital solutions to their arsenal use these machines for personalization, versioning, shorter run lengths, and in many cases, digital print is their first step into high graphics printing. Others use single-pass as a complement to their HBL RDC’s and litho-laminating equipment. Traditional two- and three-color packaging will continue its move to incorporate digital, and as we are seeing right now, subscription and e-commerce packaging use a variety of digital solutions. For display work, box plants will be looking at alternative materials and liners can open new revenue streams and should be a key consideration in any digital machine purchase.”

The increased speed and higher resolution achieved by single pass digital printing have helped corrugated makers achieve quality that may have required litho printing in the past, says Wegemer of INX. “This has improved the run size for break even, and it has allowed a larger range of work, in both packaging and displays, to move to digital. Digital can provide much more attractive graphics, as opposed to solid color coverage, at an improved value. Where some print was historically done as line work, much of this can now be accomplished economically with more attractive graphics, broadening the reach of digital on corrugated.”

Digital may also take over many day-to-day jobs currently being done with flexo, says Wegemer, due to the increased speed. “And in areas where customers may order print and warehouse portions of conventional job runs, digital may be able to take on more of this need by only running and shipping what is needed and not tying up investment in packaging inventory sitting in a warehouse,” he says. “But to accomplish this on a bigger scale, faster digital throughput is needed.”

WHAT BOX MAKERS SHOULD KNOW

Kent says that, to understand the future, it’s important to understand the past. For corrugated packaging and display producers, this means looking at a big factor slowing the adoption of digital printing: the cost of ink. “Corrugated packaging and displays have traditionally relied on big solid colors, but replicating this digitally is often cost prohibitive,” he says. “Now, with a hybrid printing option, box plants can use flexo to drastically reduce the cost of ink, offer more print enhancements, and get a higher quality final product.”

The ongoing evolution of digital printing technologies is important to keep in mind, says Lambert. “Quality, speed, unit cost, and flexibility are all changing quickly. In looking at what digital or digital hybrid might be able to do for the corrugated customers, they need to be sure to look at current technology solutions. I don’t recommend making a decision based on something you saw two years ago.”

To fully embrace the future, corrugated manufacturers should think of digital print as a rapidly evolving capability offering nearly limitless possibilities, says Seay. “Keep an open mind and look at end-to-end solutions to find the potential for the biggest savings and transformations. Working with an experienced partner can help determine how the solutions and possibilities can best meet the objectives of the company. What was once a brown box is now a marketing platform, a key component of the omni-channel brand experience.”

Paper 360

Paper 360