For years, this industry and others had looked toward 2020 as a mile-marker on many paths—particularly the road to sustainability. “20/20 Vision” became a metaphor for more than seeing perfectly; it became a way of looking ahead at the environmental performance goals being set by individual companies and the industry as a whole. The year 2020 became a convenient target date on which to pin our ambitions and investments—a chance to measure mill performance against benchmarks set five or 10 years earlier.

Of course, the 2020 we got was far different than most had pictured. As the pandemic shifted our industry’s focus toward keeping workers safe and navigating the disrupted global supply chain, we had little time to take a step back and ask, “Well, how did we do? Where do we go from here? How do we set—and meet—the new goals that will propel our industry forward?”

Paper360° Editorial Director Jan Bottiglieri posed these questions to Jukka Tiitinen, area president, North America, for Valmet. A leading global developer and supplier of process technologies, automation, and services for the pulp, paper and energy industries, Valmet has a new sustainability program, “Forward to a carbon-neutral future,” that amps up its previous targets.

P360°: Tell us a bit about Valmet’s new sustainability program. Why are such ambitious goals necessary?

TIITINEN: Climate change and global warming are significant challenges that are driving companies to rapidly transform and reduce their carbon dioxide emissions. Sustainability is not a new topic; at Valmet, and in the pulp and paper industry overall, we have been focusing on this important topic for many years, as it is a long-term commitment.

Technology plays a key role in mitigating climate change and global warming in the transition to a carbon neutral economy. This is why we have created “Forward to a carbon neutral future,” which continues our comprehensive sustainability work. Valmet´s impact can be huge through its technology, services, and automation to the pulp and paper industry.

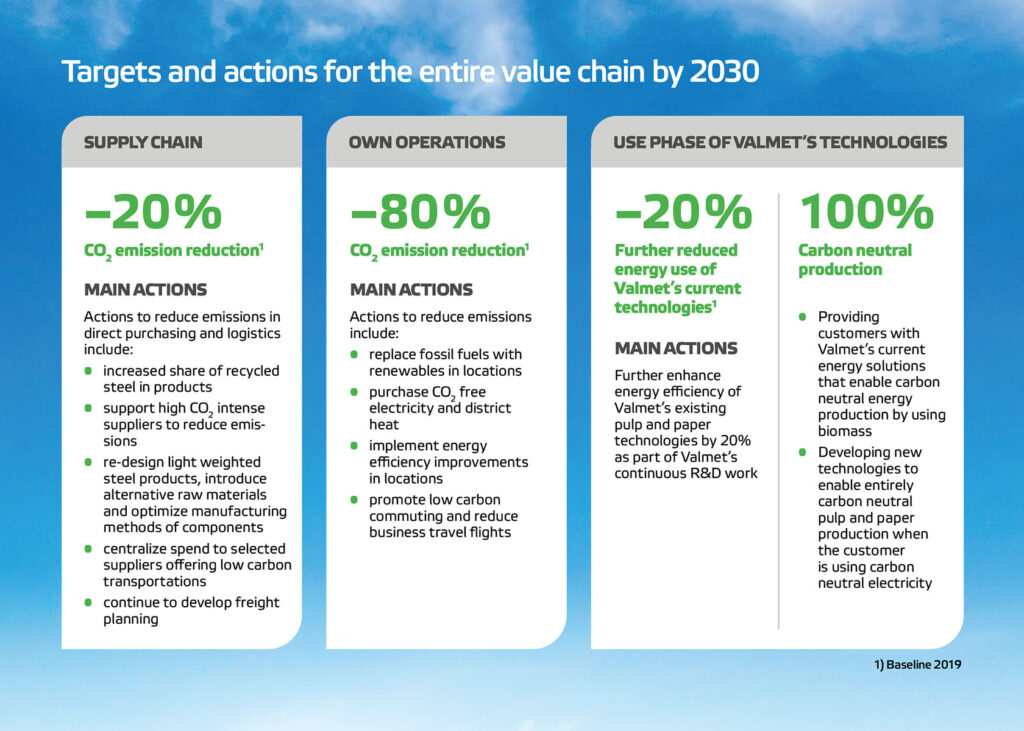

Our climate program includes ambitious CO₂ emission reduction targets and concrete actions for the whole value chain, including the supply chain, our own operations, and customers’ use of our technologies. These targets will be achieved without emission compensation. The program is aligned with the Paris Climate Agreement´s 1.5-degree pathway and the United Nations’ Sustainable Development Goals. The climate program’s targets have been approved by the Science-Based Targets initiative.

What is the goal-setting process like within Valmet? How do you set new targets, then effectively communicate these targets to team members and customers?

Valmet has a comprehensive Sustainability360° agenda with detailed actions and targets for each focus area: sustainable supply chain; health, safety and environment; people and performance; sustainable solutions; and corporate citizenship. The agenda is executed through three-year action plans. The current sustainability agenda was launched in 2014, and this year the whole agenda will be updated with detailed action plans for 2022-2024.

For example, updating Valmet’s sustainability agenda will include reviewing the latest industry analysis from a sustainability perspective, benchmarks and peer reviews, corporate sustainability trends, and regulatory analysis. Receiving input from employees, customers, suppliers, and other stakeholders is also an essential part of the work. The sustainability agenda is approved by Valmet’s Executive Team.

We promote our progress in sustainability through active stakeholder dialogue. With our customers, we have regular meetings and other direct contact such as fairs, seminars, and customer satisfaction surveys, and through specific industry organizations. With our own employees, we have very active communication through our intranet, newsletters, and information calls and sessions. In general, Valmet shares timely information about our operations through press and trade releases, the company website, several publications, and social media channels.

We focus on the most impactful areas throughout our value chain—where Valmet may have an impact, or those areas that may impact us.

How did the company achieve its previous sustainability goals—and were your efforts impacted at all by pandemic realities?

We have progressed well toward our targets through systematic work across Valmet´s business lines and areas. In 2020, we continued to implement the actions defined in the current action plan, which is ongoing for 2019–2021. We made good progress, despite the exceptional operating environment due to the pandemic.

In 2020, our efforts in supply chain were directed to ensuring our supply chain functionality and cost effectiveness during the pandemic, implementing our key supplier sustainability program, piloting remote supplier sustainability auditing, and advancing supplier collaboration to reduce CO2 emissions in our purchasing. We successfully continued to support our suppliers, and to execute and further develop our existing key processes to enhance sustainability in our supply chain.

To ensure sustainable safety development, we continued to work with safety issues locally through our safety programs, including coaching, training, communication, and injury prevention activities. Our efforts were successful, and we made good progress toward our goal of zero harm, achieving 3.1 (4.4) in total recordable incident frequency for employees.

Our personnel survey runs every second year. This gives us enough time to analyze results, define focus areas, and take required actions. Completion of high-level actions—those set at the business line, area, and global levels—was 90 percent for the 2019 survey in 2020. In addition to high-level actions, managers across the company work to execute team-level actions.

In corporate citizenship, commencing our social responsibility program, proceeding with the corrective actions related to the human rights impact assessments of our own operations, and the updating of our code of conduct were some of the 2020 highlights.

How have your pulp and paper industry customers’ own sustainability goals changed? How has Valmet been able to accommodate those customer goals with new products and services?

Our customers’ sustainability targets are tightening all over the world. Also, climate regulation to reduce emissions is being developed and implemented globally, aligned with the Paris Climate Agreement. Many of our customers have set ambitious climate targets focusing on their own operations and Valmet has a good opportunity to become the preferred partner for climate-neutral production.

Today, our customers’ chemical pulp mills provided by Valmet are usually bioenergy self-sufficient already. Furthermore, we enable carbon neutral heat and power production for our customers with our current biomass-based energy solutions.

By 2030, our target is to enable 100 percent carbon neutral production for all our pulp and paper customers by developing new process technologies. We are also improving the energy efficiency of our current offering by 20 percent.

How has Valmet adapted and improved its own manufacturing processes to meet new sustainability targets?

Our actions to reduce emissions in our own operations include:

• replacing fossil fuels with renewables in certain locations;

• purchasing CO2 free electricity and district heat;\

• implementing energy efficiency improvements in certain locations;

• promoting low carbon commuting; and

• reducing business travel flights.

A successful industry depends on many factors to be considered truly “sustainable”— for instance, innovation, workforce readiness, raw materials, and new markets. Which of these factors are particularly important to Valmet?

As stated earlier, Valmet’s Sustainability360° agenda outlines specific targets for each focus area: sustainable supply chain; health, safety, and environment; people and performance; sustainable solutions; and corporate citizenship.

In sustainable supply chain, we develop our existing processes that create the foundation for a sustainable supply chain and create new approaches to reduce the environmental impacts of our supply chain.

In HSE, we invest in safety culture and effective HSE processes and practices and collaborate with customers and partners to improve HSE results.

In people and performance, we boost employee engagement and develop the best talent. We are also a responsible employer and promote diversity.

In sustainable solutions, we create technologies and services that enhance resource and energy efficiency and the use of renewable raw materials. We also actively promote the sustainability benefits of Valmet’s offering to meet customers’ needs.

In corporate citizenship, we respect human rights and require our business partners to do the same. We also promote transparent reporting and open dialogue with our stakeholders.

Paper 360

Paper 360