The papers summarized here are from TAPPI Journal’s April 2018 issue and May 2018 issue, which feature special peer-reviewed content from the 2017 TAPPI PEERS Conference. TAPPI Journal is an online publication of relevant and timely peer-reviewed research delivered via email and free to all TAPPI members. To receive TAPPI Journal, join TAPPI at www.tappi.org.

PULPING

Online measurement of bulk, tensile, brightness, and ovendry content of bleached chemithermomechanical pulp using visible and near infrared spectroscopy

Matthew R. Tomkins, Wesley Gilbert, and Thanh Trung

Schematic of bale movement (left) and pneumatic probe in scanning position (right).

Current pulp mill practice to determine the pulp properties of bleached chemithermomechanical pulp (BCTMP) is to prepare and test handsheets for properties of interest. While use of handsheets is well established, tests require well-trained technical staff and introduce a significant lag before test results can be acted upon.

In this report, a prototype online visible and near infrared (Vis-NIR) sensor that complements handsheet testing was trialed for 16 months at a BCTMP mill. The system consists of a cabinet located near a probe installed on a conveyor belt between a slab press and a bale press.

When a bale stops on the conveyor belt, the probe rises and comes into contact with the bale, taking a spectral measurement and predicting its bulk, tensile strength, brightness, and ovendry (o.d.) content.

The online Vis-NIR sensor provides information in real time and has the potential to be used to help mills reach target grade properties more quickly, assist in the identification of inefficient chemical dousing, reduce the effect of operator bias during testing, allow for the prioritizing of laboratory tests, and improve segregation of final products according to customer needs. Further development would be necessary to use these measurements as part of a process control strategy.

CORRUGATED CONTAINERS

Importance of specimen preparation for edgewise compressive strength (ECT) testing

Jerry Loza, Doug Cash, and Benjamin Frank

Three specimens from the same material show that the top liner, which receives the initial cutter impact, has an observable edge impact.

While more than 50 years of published studies recognize the importance of rectangular, parallel edgewise compressive strength (ECT) specimens, none of the existing test methods address the degree to which a sample specimen is defined as sufficiently parallel.

In this study, researchers presented a detailed exploration of ECT results for specimens whose edges deviate from parallel with varying severity. They identified causes of variation in dimensional measurements and the corresponding ECT values across several industry standard cutters. These variations present a significant challenge to the industry in satisfying customer expectations for performance-based packaging, as well as to the development of improved predictive models for packaging performance.

This work serves as an early step for identifying or developing more optimal test methodologies to measure the inherent compressive strength of corrugated materials.

PAPERBOARD

On the nominal transverse shear strain to characterize the severity of creasing

Douglas W. Coffin and Joel C. Panek

Geometry for a generic creasing operation. Lines on the creased material show a permissible deformation of the paperboard during creasing.

Researchers used a transverse shear strain to characterize the severity of creasing for a wide range of tooling configurations. An analytic expression of transverse shear strain, which accounts for tooling geometry, correlated well with relative crease strength and springback as determined from 90° fold tests.

The experimental results show a minimum strain (elastic limit) that needs to be exceeded for the relative crease strength to be reduced. The theory predicts a maximum achievable transverse shear strain, which is further limited if the tooling clearance is negative. The elastic limit and maximum strain thus describe the range of interest for effective creasing. In this range, cross direction (CD)-creased samples were more sensitive to creasing than machine direction (MD)-creased samples, but the differences were reduced as the shear strain approached the maximum. The presented development provides the foundation for a quantitative engineering approach to creasing and folding operations.

The equation provided that characterizes shear experienced by the paperboard increasing can be used to determine multiple crease tool configurations that yield the same effect on creasing (relative crease strength or springback).

RECOVERY CYCLE

Effect of ring formation on burner flame stability in lime kilns

Girish Mohanan, Honghi Tran, Markus Bussmann, and Richard Manning

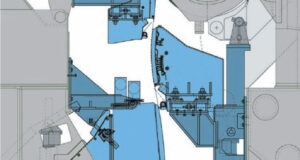

Experimental setup for investigating the effect of a long ring on burner flame pattern.

Ring formation in lime kilns is a common problem in pulp mills. Unstable burner operation that causes wide temperature variations within the kiln has been shown to be a main contributor. As rings grow thicker and longer, they are expected to affect the burner flame pattern, alter the temperature distribution, and further aggravate the problem.

This study systematically examines the effect of rings on burner operation as a function of primary air and ring characteristics, using a laboratory mock kiln. The results show that primary air greatly affects the burner flame pattern and stability. Without a ring, the flame is brighter and shorter, with an increase in primary air (PA) up to 17 percent, and blows out at 20 percent PA or higher. In the presence of a ring, the flame becomes unstable and blows out when the ring is placed near the burner, but it is more stable when the ring is placed away from the burner. Pulp mill engineers may use the information in this study to help stabilize the lime kiln burner flame.

PULPING

Dry chip feedrate control using online chip moisture

Wesley Gilbert, Ivan Trush, Bruce Allison, Randy Reimer, and Howard Mason

Normal practice in continuous digester operation is to set the production rate through the chip meter speed. This speed is seldom, if ever, adjusted except to change production, and most of the other digester inputs are ratioed to it. The inherent assumption is that constant chip meter speed equates to constant dry mass flow of chips. This is seldom, if ever, true. As a result, the actual production rate, and effective alkali (EA)-to-wood and liquor-to-wood ratios, may vary substantially from assumed values. This increases process variability and decreases profits.

In this study, researchers develop a new continuous digester production rate control strategy that addresses this shortcoming. A new noncontacting near infrared–based chip moisture sensor is combined with the existing weightometer signal to estimate the actual dry chip mass feedrate entering the digester. The estimated feedrate is then used to implement a novel feedback control strategy that adjusts the chip meter speed to maintain the dry chip feedrate at the t

Schematic of bale movement (left) and pneumatic probe in scanning position (right).

arget value. The report details the results of applying the new measurements and control strategy to a dual vessel continuous digester.

A new method of dry chip feedrate control could help mills stabilize and potentially increase production rates and achieve better production quality when combined with existing liquor dosing controls.

RECOVERY CYCLE

Use of vent stack temperature as a feedforward variable for dissolver total titratable alkali (TTA) control

Wei Ren, Brennan Dubord,

Jason Johnson, and Bruce Allison

Tight control of raw green liquor total titratable alkali (TTA) may be considered an important first step toward improving the overall economic performance of the causticizing process. Dissolving tank control is made difficult by the fact that the unknown smelt flow is highly variable and subject to runoff. High TTA variability negatively impacts operational costs.

Current practice is to use feedback control to regulate the TTA to a target value through manipulation of weak wash flow while keeping dissolver density within acceptable limits. Unfortunately, the amount of variability reduction that can be achieved by feedback control alone is fundamentally limited by the process dynamics.

One way to improve the situation would be to measure the smelt flow and use it as a feedforward control variable. Direct measurement of smelt flow is not yet possible. This study investigates the use of an indirect measurement, the dissolver vent stack temperature, as a surrogate feedforward variable for dissolving tank TTA control. Mill trials indicate that significant variability reduction in the raw green liquor TTA is possible and that the control improvements carry through to the downstream processes.

Implementing feedforward control at the dissolving tank can reduce raw green liquor TTA variability, which leads to improved operation at the slaker. Feedforward control can also minimize the impact of smelt run-offs and improve safety at the dissolving tank.

OTHER RESEARCH IN TAPPI JOURNAL’S APRIL 2018 ISSUE:

RECOVERY CYCLE

Monitoring the free lime content in lime mud using zeta potential

Wei Ren and Honghi Tran

OTHER RESEARCH IN TAPPI JOURNAL’S MAY 2018 ISSUE:

CORROSION

A hundred years of corrosion in the pulp and paper industry

Max Moskal

EMISSIONS

Factors affecting particulate removal efficiency of kraft recovery boiler electrostatic precipitators: A technical review

Ezzat Jaroudi, Ivan Sretenovic, Greg Evans, and Honghi Tran

Paper 360

Paper 360